For over 165 years, the Siemens AG technology group has been synonymous worldwide with technical performance, innovation, quality and reliability. Siemens Österreich has been present in the Alpine republic for over 135 years now and is among the leading technology companies there. The core business in Austria concentrates on electrification, automation and digitalisation. System supplier Ersa recently installed its first plant there: Versaflow 4/55 with the Versaflex selective soldering module.

Electricity is our most important source of power and the ever-increasing levels of automation and interconnectedness make a reliable electricity supply indispensible. Regardless of the branch, requirements or application, an efficient power supply is a fundamental necessity for all plant operations. Within Siemens AG Österreich, the business division Siemens Industrial Manufacturing, Engineering and Applications (SIMEA for short) is the dynamic hub for development, engineering and manufacturing of PCBs, devices and components.

One of the main points of focus at the Vienna site is industrial power supply. There, and in the Sibiu site in Rumania, Siemens produces customised power supply systems and components, such as the regulated direct power unit SITOP, which are then used worldwide in automation, drive and building technologies as well as in the wind energy and medical engineering sectors. The core competences are development and product management, industrialisation of power electronics and engineering of customer projects as well as prototyping and test engineering.

Diverse variant soldering without changeover time

For production of the new generation of power supply units, LOGO!Power – deployed primarily in distribution boards – SIMEA realised the need for a new production line. Features of the new mini power supply units include great performance in the smallest space, effective operation thanks to excellent efficiency over the complete load range and lowest performance loss during idle times, as well as various performance classes with different output voltages.

The requirements on the remit for the machine manufacturer were therefore formulated as follows: “Soldering diverse variants without changeovers, in the required cycle time.” The challenge lay, on the one hand, in the layout of the boards – there were three different circuit board panels, all differing in terms of size and proximity of the connections, as LOGO!Power is available in three different versions. Every panel consists of six main circuit boards and six sub-circuit boards, and the panels are not in parallel. “The sub-circuit boards are set at an angle of 90° in the panels and are later soldered onto the main circuit boards. The second and even greater challenge was the required cycle time of 40 seconds, which absolutely had to be observed,” explains Harald Schmidt, process technician – soldering at SIMEA.

With this challenging remit, Siemens approached the system supplier Ersa in Wertheim. Part of the tender was an application report for which test boards to be soldered were provided by SIMEA. Once the test boards arrived in Wertheim from Vienna, it soon became clear just how complex and demanding the task actually was.

While it was possible to work in parallel on the six main circuit boards with a y-variable double-pot, one could not reach the sub-circuit boards. This would have required a second soldering module with a single nozzle or a dip module. However, this arrangement would have made it impossible to meet the required cycle time of 40 seconds – the very thing defined as absolutely necessary in the specifications. Furthermore, this arrangement would have required higher tooling costs and changeovers, which SIMEA also wanted to avoid.

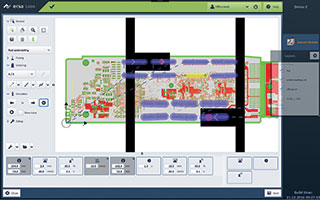

It was therefore decided at Ersa that the problem would be tackled with the Versaflow 4/55 high-end selective soldering plant – fitted with the extremely flexible Versaflex selective soldering module. This allowed the required cycle time to be observed while at the same time guaranteeing the standard of quality.

The inserted pins fitted and there were no solder bridges, even with small pin interspaces. The results of the soldering test were recorded in an application report and presented to SIMEA. “This application report and the observance of the cycle times were crucial to our decision for Ersa,” says Schmidt, and continues: “Only with the use of the Versaflex was it possible to achieve the required cycle time of 40 seconds per unit. The two tasks for the circuit board panel – pre-soldering of the sub-boards and soldering of the sub-boards to the motherboards are simply not possible – with the required quality and cycle time – on any other soldering plant. The enormous flexibility offered by the Versaflex selective soldering module is one of a kind on the market and does away with the need for a second soldering module.”

Double pots working completely independently

The two solder pots in this innovative, fully new double soldering module are mounted on two independent axes. This allows Versaflex to be used in conventional parallel operation but also in an asynchronous mode, so that both pots work completely independently of one another – this functionality really came into its own in this project. This is because, as each solder pot is mounted on a separate axis system, x-, y- and z-direction can be set completely individually.

A further crucial factor for Harald Schmidt was the software with clear, simple operation and programmability – in the soldering programme, the parameters for each component on the board, such as flux application, wave pressure or soldering speed can be individually adjusted. “I am no longer forced to handle the entire product with an average value. This gives me greater flexibility and reduces soldering errors,” says the THT expert.

The software calculates the optimum paths for the nozzles and shares the solder between two soldering nozzles. The pots then do their jobs completely independently of one another – the result is optimised, shortest possible cycle times and, consequently, increased throughput.

Smart features bring efficiency and productivity

Today, almost all forms of electronics manufacturing are subject to enormous cost pressure. The aim is to make as few errors as possible, ideally none at all. Process reliability and zero-fault production have become almost second nature for all electronics manufacturers. In this context too, Ersa was able to score with the Versaflow: the selective soldering system contains a setup verification feature ensuring that the right soldering tool has been attached. Process cameras monitor, for example, soldering wave height and nozzle wetting; if required, the correction process is triggered and carried out.

For the peripherals, i.e. transport belts from the picking and placing stations to the soldering unit and lifting and lowering stations, Siemens Österreich brought in the materials handling and automation specialists Pacha Automation – no stranger to Ersa either, since the two companies have been working together as trusted partners for many years. In this specific case, Pacha tailored the peripherals perfectly to SIMEA’s requirements and manufacturing needs and the chosen Ersa Versaflow 4/55.

After processing the LOGO!Power circuit board panels in the soldering system, the product is returned to the pick and place stations via a lifting and lowering station and a conveyor belt under the soldering system. The sub-boards are further processed directly on the next board, i.e. fitted out on the main boards.

The sub-boards are also prepared for soldering before the complete panel is sent off on its journey through the Versaflow. The finished motherboards are removed from the panels and sent on for final assembly. Aptly, the SITOP!Power units are used for power supply in the Versaflex soldering plants.

Competent consultation and top soldering quality

“In addition to cycle times and quality, support and advice are vital decision criteria for us when it comes to investing in new equipment,” says Schmidt. “In Ersa we have found a partner we regard as exemplary. The cooperation is uncomplicated and very pleasant, reaction time extremely short and we receive very competent advice. The plant is reliable in operation and delivers top soldering quality.

“The Versaflex selective soldering module is the ideal solution for us: We manage without a second soldering module or a high-cost dip solution which would also require setup time when changing production. The ERSASOFT 5 machinery software with CAD Assistant 4 is a true highlight – making programme generation or adaptation really easy; and it even works while production is ongoing. Here, Ersa gives us the kind of flexibility that no other manufacturer can provide in this form at the moment.”

The Versaflow 4/55 selective soldering plant with Versaflex soldering module is Ersa’s first machinery project for SIMEA in Vienna. All those involved in the successful implementation see it as a sound basis for future projects.

For more information contact Techmet, +27 (0)11 824 1427, info@techmet.co.za, www.techmet.co.za

| Tel: | +27 11 824 1427 |

| Fax: | +27 11 824 3150 |

| Email: | sales@techmet.co.za |

| www: | www.techmet.co.za |

| Articles: | More information and articles about Techmet |

© Technews Publishing (Pty) Ltd | All Rights Reserved