Safety of lithium-based batteries has attracted much media and legal attention. Any energy storage device carries a risk, as demonstrated in the 1800s when steam engines exploded and people got hurt. Carrying highly flammable gasoline in cars was a hot topic in the early 1900s. All batteries carry a safety risk, and battery makers are obligated to meet safety requirements; less reputable firms are known to make shortcuts and it’s ‘buyer beware!’

Safety of lithium-based batteries has attracted much media and legal attention. Any energy storage device carries a risk, as demonstrated in the 1800s when steam engines exploded and people got hurt. Carrying highly flammable gasoline in cars was a hot topic in the early 1900s. All batteries carry a safety risk, and battery makers are obligated to meet safety requirements; less reputable firms are known to make shortcuts and it’s ‘buyer beware!’

Lithium-ion is safe but with millions of consumers using batteries, failures are bound to happen. In 2006, a one-in-200 000 breakdown triggered a recall of almost six million lithium-ion packs. Sony, the maker of the lithium-ion cells in question, points out that on rare occasions microscopic metal particles may come into contact with other parts of the battery cell, leading to a short circuit within the cell.

Battery manufacturers strive to minimise the presence of metallic particles. The semiconductor industry has spent billions of dollars to find ways of reducing particles that reduce the yield in wafers. Advanced clean rooms are Class 10 in which 10 000 particles larger than 0,1 μm per cubic metre are present (ISO 4 under ISO 14644 and ISO 14698). In spite of this high cleanliness, particle defects still occur in semiconductor wafers. Class 10 reduces the particles count but does not fully eliminate them.

Battery manufacturers may use less stringently controlled clean rooms than the semiconductor industry. While a non-functioning semiconductor simply ends up in the garbage bin, a compromised Li-ion battery can make its way into the workforce undetected and deteriorate without knowing. Resulting failures are especially critical with the thinning of the separators to increase the specific energy.

Cells with ultra-thin separators of 24 μm or less are more susceptible to impurities than the older designs with lower Ah ratings. Whereas the 1350 mAh cell in the 18650 package could tolerate a nail penetration test, the high-density 3400 mAh can ignite when performing the same test. New safety standards direct how batteries are used, and the UL1642 Underwriters Laboratories (UL) test no longer mandates nail penetration for safety acceptance of lithium-based batteries.

Li-ion using conventional metal oxides is nearing its theoretical limit on specific energy. Rather than optimising capacity, battery makers are improving manufacturing methods to enhance safety and increase calendar life. The real problem lies when on rare occasions an electrical short develops inside the cell. The external protection peripherals are ineffective to stop a thermal runaway once in progress. The batteries recalled in 2006 had passed the UL safety requirements, yet they failed under normal use with appropriate protection circuits.

There are two basic types of battery failures. One occurs at a predictable interval-per-million and is connected with a design flaw involving the electrode, separator, electrolyte or processes. These defects often involve a recall to correct a discovered flaw. The more difficult failures are random events that do not point to a design flaw. It may be a stress event like charging at sub-freezing temperature, vibration, or a fluke incident that is comparable to being hit by a meteor.

Let’s examine the inner workings of the cell more closely. A mild short will only cause elevated self-discharge and the heat build-up is minimal because the discharging power is very low. If enough microscopic metallic particles converge on one spot, a sizable current begins to flow between the electrodes of the cell, and the spot heats up and weakens. As a small water leak in a faulty hydro dam can develop into a torrent and take a structure down, so too can heat build-up damage the insulation layer in a cell and cause an electrical short. The temperature can quickly reach 500°C, at which point the cell catches fire or it explodes. This thermal runaway that occurs is known as ‘venting with flame.’ ‘Rapid disassembly’ is the term preferred by the battery industry.

Uneven separators can also trigger cell failure. Poor conductivity due to dry areas increases the resistance, which can generate local heat spots that weaken the integrity of the separator. Heat is always an enemy of the battery.

Most major Li-ion cell manufacturers X-ray every single cell as part of automated quality control. Software examines anomalies such as bent tabs or crushed jelly rolls. This is the reason why Li-ion batteries are so safe today, but such careful manufacturing practices may only be offered with recognised brands.

What to do when a battery overheats

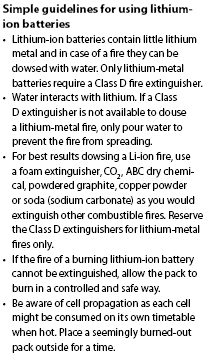

If a Li-ion battery overheats, hisses or bulges, immediately move the device away from flammable materials and place it on a non-combustible surface. If at all possible, remove the battery and put it outdoors to burn out.

A small Li-ion fire can be handled like any other combustible fire. For best results use a foam extinguisher, CO2, ABC dry chemical, powdered graphite, copper powder or soda (sodium carbonate). If the fire occurs in an aeroplane cabin, the FAA instructs flight attendants to use water or soda pop. Water-based products are most readily available and are appropriate since Li-ion contains very little lithium metal that reacts with water. Water also cools the adjacent area and prevents the fire from spreading. Research laboratories and factories also use water to extinguish Li-ion battery fires. Halon is also used as a fire suppressant, but this agent may not be sufficient to extinguish a large Li-ion fire in the cargo bay of an aircraft.

A large Li-ion fire, such as in an electric vehicle (EV), may need to burn out as water is ineffective. Water with copper material can be used, but this may not be available and is costly for fire halls. When encountering a fire with a lithium-metal battery, only use a Class D fire extinguisher. Lithium-metal contains plenty of lithium that reacts with water and makes the fire worse. As the number of EVs grows, so must the methods to extinguish such fires.

During a thermal runaway, the high heat of the failing cell inside a battery pack may propagate to the next cells, causing them to become thermally unstable also. A chain reaction can occur in which each cell disintegrates on its own timetable. A pack can thus be destroyed in a few seconds or over several hours as each cell is being consumed. To increase safety, packs should include dividers to protect the failing cell from spreading to the neighbouring one.

The gas released by a venting Li-ion cell is mainly carbon dioxide (CO2). Other gases that form through heating are vaporised electrolyte consisting of ethylene and/or propylene. Burning gases also include combustion products of organic solvents.

While lithium-based batteries are heavily studied for safety, nickel- and lead-based batteries also cause fires and are being recalled. The reasons are faulty separators resulting from ageing, rough handling, excessive vibration and high temperature. Lithium-ion batteries have become very safe and heat-related failures occur rarely when used correctly.

For more information contact Michael Rogers, Uniross Batteries, +27 (0)11 466 1156, [email protected], www.uniross.co.za

| Tel: | +27 11 466 1156 |

| Fax: | +27 11 466 9109 |

| Email: | [email protected] |

| www: | www.uniross.co.za |

| Articles: | More information and articles about Uniross Batteries |

© Technews Publishing (Pty) Ltd | All Rights Reserved