Customers often ask about data cable categories and what they mean. For many end users, engineers and purchasing agents, who don’t work with these types of cables on a daily basis, the different categories can seem complicated and overwhelming.

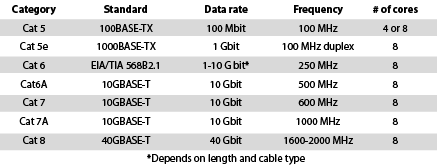

However, what appears to be complex at first glance, can be simple to understand with a couple of tips. The category positively correlates with the data speed, i.e., the higher the category, the higher the possible frequency and the higher the frequency, the higher the possible data rate.

Data cable basics

One can compare category cables to a multi-lane road; the more lanes a road has, the more vehicles that are able to travel on this road concurrently. The standards are generally based on a maximum cable length of 100 m. This cable length consists of 90 m of installation cable and 10 m of patch cable. After the initial 100 m a repeater/extender is added to the cable system, which strengthens the signal and prepares it to be transmitted an additional 100 m as needed to connect the machine or its apparatus, and the control unit. Additionally, category data cables have to fulfil decoupling values of the pairs, e.g., near end cross talk (NEXT).

For Cat 5 cables, the decoupling of the pairs is realised in the cable construction with different twisting lengths of each pair. That means for four pairs, there are four individual twisting lengths during production. The effectiveness of the twisting is not able to reach the target values and additional steps have to be added during cable construction for higher categories.

Cat 6 cables allow a choice between two technical designs. The relevant decoupling values of Cat 6 can be achieved with a plastic cross that creates distance between the pairs. Another way is to use a pair in metal foil (PIMF) construction.

The thickness of the aluminium foil influences the effectiveness of the screen. Many people think that a screen in the construction protects the cable from environmental influences. However, it also has the opposite effect – the screen keeps the electrical signal in the cable and avoids negatively influencing other equipment in the vicinity.

For even higher categories, such as Cat 7, 7e and 7A, a copper braid is mandatory to fulfil the standardised electrical values because an aluminium foil alone is not enough. Furthermore, each screening material has advantages and disadvantages.

Aluminium foil is inexpensive, but by itself this material does not perform well in applications that require flexible, track or torsion cables. If a metal foil is moved again and again cracks start to appear, which decreases the effectiveness of the screening in the cable. This is the reason some manufacturers construct cables that move frequently or are located in electromagnetic vulnerable (EMV) areas using both an aluminium foil screen and a copper braid. This applies even to cables that are ‘only’ Cat 5 classification.

For cables with high numbers of bending cycles and small bending radii, some manufacturers use an additional metallised tape to fulfil effective screening.

This is similar to a woven tape with integrated metallised parts, which offers longer lifespan without cracking compared to a standard aluminium foil.

Cable markings

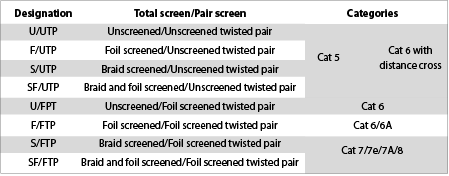

Cable manufacturers quite often receive questions about the markings on the data cables, such as U/UTP or SF/UTP. The identification marks before the forward slash symbol (/) refer to the overall cable screen; the identification marks after the forward slash refers to the screening of the pairs. Table 2 shows some common data cable markings.

Core material options

There are a variety of possible core options, from both a material and stranding perspective. In most applications, bare copper is the preferred core material to use. However, in specific applications, such as the railway industry, a tinned copper core is preferred due to its higher corrosion resistance.

In terms of core stranding, solid cores are typically used in fixed installations, while flexible applications require a more nimble core which typically consists of seven strands. Flexible cores are used for drag chains and robotic applications with short lay length in order to achieve a more flexible cable and smaller bending radius.

For the smallest bend radii and maximum cycle quantity/service life, customers can request to have data cables constructed with 19-strand cores. The more strands in a core increases its flexibility; however, the best solution for a specific application and respective technical specifications should be discussed in consultation with the cable manufacturer.

Once the construction of the core has been defined, it’s time for the next production steps: insulation extrusion, twisting of the individual cores into pairs (or four cores known as a star quad), screening, and lastly, the outer sheath. Each production step is geared toward the customer’s specific application and technical requirements to achieve a design which ensures the highest operational safety and reliability. Construction examples include:

• Cores with long lay lengths for fixed cable installations, and short lay lengths for flexible and high-flex applications.

• Aluminium foil screen for fixed installation, because the aluminium cracks after a few cycles, thereby decreasing the screen quality. When aluminium foil is used as a screen in flexible applications, it is always in combination with a copper braid, and the aluminium foil is incorporated into the screening process.

• Braided screens with long lay length for fixed installations, but short lay length for flexible and continuous flex applications.

Sheath material options

Cable sheath types are plentiful and can be narrowed down to what application the cable will be performing in. For cable installations in buildings, polyvinyl chloride (PVC) or flame retardant non-corrosive (FRNC) compounds are the typical choice of sheath material.

PVC is not halogen-free, but it is flexible and inexpensive. FRNC compounds meet the requirements of being halogen-free and flame-retardant, and emit a less optically dense smoke, which makes exiting a building easier and allows for improved fire fighting operations in the event of a fire emergency. Polyethylene (PE) sheaths are mainly used for outdoor cable applications and/or in cases where a cable needs to be buried into the ground. These cable sheaths are good at resisting moisture and exposure to the sun.

Due to the increase of data cables being used in industrial automation, it is common in such applications to use oil-resistant PVC blends, polyurethane (PUR) or thermoplastic elastomer (TPE) sheath compounds. These cable sheath types are preferred for their increased oil resistance, and ability to withstand the mechanical stresses often associated with the use of drag chains and robotics. The choice of a particular compound or blend is based on the application and operating conditions.

Cable quality

Finally, it is highly recommended to have data cables that have had their mechanical capabilities extensively tested to withstand the rigors of operating in continuous-flex (drag chains) and torsion (robotics) applications. Data transmission rates can lessen or signal quality could erode due to cables that are unable to withstand strenuous operating conditions.

Manufacturers should use a combination of test equipment, such as drag chains, torsion apparatuses, ovens and freezers, and, in some cases, specific application testing rigs, such as towers that mimic the strain and load on cables found inside wind turbines.

| Tel: | +27 11 462 8752 |

| Fax: | +27 11 462 8638 |

| Email: | sales@helukabel.co.za |

| www: | www.helukabel.co.za |

| Articles: | More information and articles about Helukabel SA |

© Technews Publishing (Pty) Ltd | All Rights Reserved