Charge and discharge currents increase the temperature of batteries and temperature directly affects their lifespan and storage capacity. Batteries tend to be efficient and provide a normal life span at room temperatures, but when they are subjected to cold temperatures, their capacity is greatly reduced and as temperatures increase above room temperature, their life span is reduced. At extreme temperatures, batteries can break down in several stages: leakage, smoke, fire and explosion. Manufacturers often perform abuse tests to determine the temperatures for each of the stages of breakdown.

The increased adoption of consumer mobile devices has made measurement of heat relevant, particularly for when batteries charge and discharge. The rule of thumb for electronic devices is that for every 10°C rise in temperature, the average reliability of an electronic device decreases by 50%. Or, if the temperature is lowered by 10°C, the reliability will double. In other words, the expected meantime between failures ratings (MTBF) can be improved by two times, if the operating temperature is lowered by 10°C.

This article provides advice for selecting test instrumentation to set up and make accurate battery charge and discharge temperature measurements to aid in making the appropriate capacity or lifespan trade-off, and improve the reliability of a product or device.

Why choose a DAQ?

Basic temperature measurements can be made with an infrared digital thermometer, or a digital multimeter (DMM) with a thermocouple hooked up.

So, why choose a DAQ instrument?

It is beneficial to use a DAQ when:

• It is necessary to measure multiple temperature points in a single setup.

• Other types of measurements such as voltage, current, resistance or frequency are necessary in the same test setup.

• Needing to perform data logging over a period, and memory space is a potential issue.

Keysight supplies the 34970A and 34972A general-purpose DAQ instruments that can be used for temperature measurements. Because they can measure across various input signals including AC/ DC voltage, AC/DC current, 2/4-wire Ω, frequency and period, they are incredibly versatile.

Selecting a multiplexer

Multiplexers allow a single measurement system to measure multiple channels. Temperature measurements often use several thermocouples or other sensors, so multiplexers provide a way to connect each one to the measurement system. The multiplexer will also scan the sensors, measure one at a time and then automatically move to the next one.

Multiplexers work well for temperature measurements because temperature changes much slower than the scan rate. Here are several multiplexer options for temperature measurements:

Select a multiplexer with a built-in thermocouple reference junction when you need to obtain absolute temperature measurements. Keysight’s 34901A and 34902A offer this built-in capability.

Determine the number of channels needed for your application. Each multiplexer provides a different number of channels available for testing. Keysight’s 34908A provides up to 40 channels.

Scanning speed of up to 60 channels per second is sufficient for most temperature measurement applications. If needed, faster scanning is available with the 34902A multiplexer, at up to 250 channels per second.

Most multiplexers can accept other types of input signals besides temperature, such as AC/DC Volts, 2-wire Ω, frequency and period. Some multiplexers can also measure AC/DC current.

Multiplexers can also measure temperature using thermistors and RTDs. More accurate measurements can be made using 4-wire Ω measurements. The 349701A and 34902A are capable of both 2- and 4-wire Ω measurements.

Choice of temperature sensors

The 34970A and 34972A DAQ models have universal inputs with built-in signal conditioning circuitry and software algorithm. This gives the flexibility to choose from a range of temperature sensors.

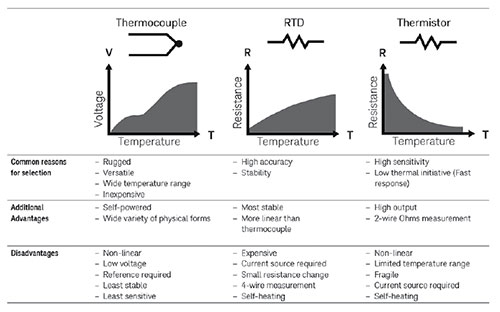

Thermocouple

Popular thermocouple sensor types are the type B, E, J, K, N, R, S and T. Thermocouple types vary by their operating range, chemical properties, sensitivity, melting point and output.

Depending on the test environment, some thermocouple types are more suited for use than others. As mentioned earlier, absolute temperature measurements are attainable with the thermocouple reference junction built into the 34901A, 34902A and 34908A multiplexers.

Resistance temperature detector (RTD)

There is a choice of 2-wire and 4-wire type RTD sensors. The 4-wire type RTD sensor should be used if the leads are very long as this can affect the accuracy of temperature measurements. RTD sensors are known for having superior stability, accuracy and resistance-temperature linearity over other temperature sensors such as the thermocouple and thermistor.

Thermistor

Thermistors are either negative temperature coefficient (NTC) or positive temperature coefficient (PTC) types. With NTC, resistance decreases as temperature rises while with PTC, resistance increases with temperature. NTC type thermistors are more common, with ranges that include the 2,2 kΩ, 5 kΩ and 10 kΩ types. Thermistors are more sensitive than thermocouple or RTD sensors but are not as linear as an RTD.

Considerations for data-logging and analysis

It was mentioned earlier that a DAQ device is recommended for temperature measurement, especially when multiple temperature points are involved or when temperature needs to be data logged and monitored over a period. As a DAQ instrument needs to be connected to a PC, some software applications are necessary for instrument connection, configuration and data logging. An application that provides visualisation, graphing and reporting capability can also be beneficial.

Several test vendors offer software applications to connect, control and automate test instrumentation. Keysight offers BenchVue software, which provides an intuitive user interface to quickly set up and execute tests, and then get results faster. The Test Flow feature allows the user to build their own automated tests, reducing significant test development time.

BenchVue supports hundreds of Keysight instrument types and models, and dedicated instrument apps are automatically launched upon instrument detection. The BenchVue Data Acquisition Control & Analysis app can be used for data acquisition, data logging and data visualisation. The app provides multiple data visualisation displays and math capabilities, making it a powerful time-saving tool for instant monitoring, analysis and reporting.

For more information contact Concilium Technologies, +27 (0)12 678 9200, info@concilium.co.za, www.concilium.co.za

| Tel: | +27 12 678 9200 |

| Email: | info@concilium.co.za |

| www: | www.concilium.co.za/test-measurement |

| Articles: | More information and articles about Concilium Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved