Designed for use in a wide variety of consumer and industrial applications, STMicroelectronics’ 6-axis iNEMO inertial measurements units (IMU) feature an embedded machine learning core (MLC) to offload the burden from the host processor. Machine learning is an application of artificial intelligence (AI) through which a machine can learn, by itself or in a supervised way, without explicit programming. It provides a system the ability to automatically learn and improve from experience without compromising the accuracy of the data collected.

The machine learning processing capability allows for moving some algorithms from the host processor to the IMU (inertial measurement unit). The IMU would therefore only consume less than one hundredth of the MCU (microcontroller) power used for the same typical tasks. The MLC is designed to run in a highly power-efficient manner and provides accurate results in the shortest possible time. A meta-classifier is also available to further enhance data accuracy in specific cases.

Developers of applications using sensors can thus benefit from the advantages of machine learning by creating their decision trees (using large data sets and high processing power) and having them run on an optimised MLC in the same sensor device.

Decision trees can be created and updated much faster using machine learning compared to explicit programming when appropriate data sets are available. The machine learning processing capability allows moving some algorithms from the host processor to the IMU. For typical tasks the IMU would consume 0,001 times the power of an MCU used for the same task. This is a key enabler for ultra low-power edge-computing. iNEMO IMUs with MLC can be configured to run up to eight decision trees simultaneously and independently, giving added flexibility to developers.

The LSM6DSOX contains a 3-axis accelerometer and 3-axis gyroscope and tracks complex movements using the machine learning core at low typical current consumption of just 0,55 mA to minimise load on the battery.

The consumer-grade LSM6DSRX contains a 3-axis accelerometer and a 3-axis gyroscope with extended full-scale angular rate range up to +/-4000 dps.

The industrial-grade ISM330DHCX comes with 10-year product longevity assurance and is specified from -40°C to 105°C, with embedded temperature compensation for superior stability.

Intelligent sensing with iNEMO inertial measurement units

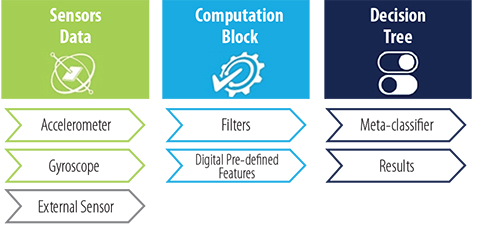

iNEMO IMUs are built around three blocks, as shown in Figure 1.

The built-in sensors (accelerometer and gyroscope) filter real-time motion data before sending it to the computation block where statistical parameters defined as ‘features’ are applied to the captured data. The features aggregated in the computation block will be used as input for the third block of the machine learning core.

The decision tree evaluates the statistical parameters and compares them against certain thresholds to identify certain situations and generate results sent to the MCU. The machine learning core results are the decision tree’s output results which include the optional meta-classifier.

Building your decision trees,

iNEMO IMUs offer a wide range of design possibilities for developers by allowing them to create their own embedded machine learning algorithms and to build the best decision tree for their application.

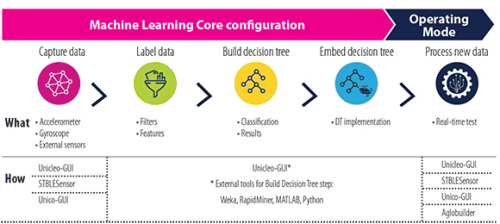

1. Collect data

The first step is to collect a representative set of data for the motion-related application being modelled. Examples of physical parameters include acceleration, temperature, sound, pressure, magnetic field, depending on your application.

2. Label and filter data and configuration features

Once the data is collected, a label is assigned to each statistical data pattern associated with an identified outcome, e.g. ‘jogging’ or ‘failure mode’. The computation blocks, i.e., the filters and features, can then be configured. The features are statistical parameters computed from the input data (or from the filtered data) in a defined time window, selectable by the user based on the specific application.

3. Build the decision tree

Use a machine learning tool for data mining tasks (such as Weka, Rapidminer, Matlab, Python), to generate settings and identify limits in the sample data to build a decision tree which recognises the type of motion data to be detected.

4. Embed the decision tree in the MLC

Weka or similar tools then generate a configuration file that is uploaded into the sensor and you are ready to go.

Operating mode: process new data using a trained decision tree

Finally, when the device is programmed, the machine learning core results can be processed using the defined, trained decision tree in your application. Developers can also get support and exchange ideas in the MEMS and Machine Learning and AI community page on the STMicroelectronics website (www.st.com).

| Tel: | +27 11 923 9600 |

| Email: | info@arrow.altech.co.za |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

© Technews Publishing (Pty) Ltd | All Rights Reserved