Consumers are increasingly interested in monitoring their own health due to both increased health awareness and the ability to use monitoring to prevent or treat various diseases. For instance, diabetes, obesity, and high cholesterol levels are pervasive problems – due in no small part to changes in lifestyles – while at the same time, the proliferation of smartphones and wearable devices enables consumers to use health monitoring applications to assist them in maintaining optimal health.

Patient-centric healthcare applications inform users of medication times, number of calories consumed, dehydration levels in the body, and so forth.

This increasing trend toward healthcare information technology systems enables practitioners to access patient data if the patient consents. Routine checkup of lab reports, as well as easy access to radiology and pathology reports from mobile devices will no doubt boost the growth of patient-centric healthcare applications. Figure 1 shows an example of a monitoring system.

Medical devices

Analog Devices has serviced the medical market for many decades. We have observed that low-power precision components have enabled the rapid growth of portable and wireless medical devices. These types of medical products generally have high standards for reliability, run time, and robustness, with much of this burden falling on the power management system and its components. Medical monitoring products must operate properly and switch seamlessly between a variety of power sources such as batteries, AC mains outlets, supercapacitors, and even harvested ambient energy sources.

The power system architect must design a system that is protected against, and must sometimes tolerate, fault conditions to maximise operating run time – if powered from batteries – while also ensuring that normal system operation is reliable whenever a valid power source is present.

Another trend fuelling the growth of portable and wireless medical instrumentation is a change in patient care. Specifically, this can be attributed to the increased use of remote monitoring systems within a patient’s own home. One reason for this trend is economic – the costs of keeping a patient in a hospital are prohibitive – both for the patient and the medical provider. This accounts for the growing trend of portable electronic monitoring systems that incorporate radio frequency (RF) transmitters, so that any data gathered from the patient can be sent directly back to a supervisory system within the hospital or doctor’s office for later review and analysis.

It is reasonable to assume that the cost of supplying the appropriate medical instrumentation to the patient for home use is more than offset by the cost of keeping them in the hospital for observation purposes. Nevertheless, since the equipment will not be used under professional supervision, it is of paramount importance that the equipment used by the patient is safe and reliable.

The manufacturers and designers of these products must ensure that equipment can run seamlessly from multiple power sources and have high reliability in the wireless transmission of the data collected from the patient. This requires the power management and conversion architecture to be robust, flexible, compact, efficient, and low-noise over a wide bandwidth.

Power conversion architecture

Although switching regulators generate more noise than linear regulators, their efficiency is generally far superior. Noise and EMI levels have proven to be manageable in many noise-sensitive applications if the switcher behaves predictably. If a switching regulator switches at a constant frequency in normal mode, and the switching edges are clean and predictable with no overshoot or high-frequency ringing, then EMI is minimised.

A small package size and high operating frequency can provide a small, tight layout, which minimises EMI radiation. Furthermore, if the regulator can be used with low-ESR ceramic capacitors, both input and output voltage ripple can be minimised. Nevertheless, not all system architects have a comprehensive switch-mode power conversion background to address these noise interference aspects.

Many of these systems also require a number of various low-voltage rails for powering low-power sensors, memory, microcontroller cores, I/O, and logic circuitry, further complicated by thermal design constraints due to a lack of air flow or heatsinking for cooling purposes.

Analog Devices’ Power by Linear product group has focused on power supply solutions with industry-leading products and power experts. For example, there are many applications in medical electronic systems that require continuous power even when the main supply is interrupted, requiring robust backup power. The backup run time of these systems is generally defined by the time the system needs to shut down properly after its main supply is lost. This time varies from minutes to hours depending on the end application.

New solutions to ease design constraints

Supercapacitors are an excellent choice for systems that need high power, short duration backup power. Any IC that supports this type of application would typically require the capability to support 2,9 V to 5,5 V supply rails during a main power interruption. Supercapacitors have high peak power capabilities, making them an ideal choice for systems whose applications require high peak power backup for brief time intervals.

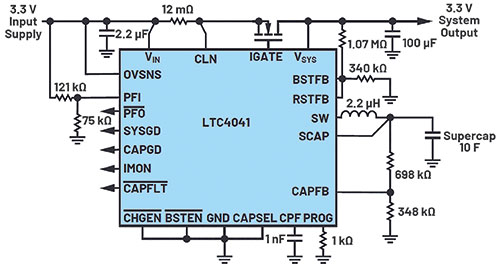

For instance, the LTC4041 uses an on-chip, bidirectional, synchronous converter to provide high efficiency step-down supercapacitor charging, as well as high current, high efficiency boost backup power. When external power is available, the device operates as a step-down charger for one or two supercapacitor cells while giving preference to the system load. When the input supply drops below the adjustable power fail indicator (PFI) threshold, the LTC4041 switches to boost mode operation and can deliver up to 2,5 A to the system load from the supercapacitor.

During a power fail event, the device’s PowerPath control provides reverse blocking and a seamless switchover from input power to backup power. Typical applications for the LTC4041 include ride-through dying gasp supplies such as those typically found in medical equipment, power meters, industrial alarms, and solid-state drives. Figure 2 shows a typical LTC4041 application schematic.

If two supercapacitors are used, an internal supercapacitor balancing circuit maintains equal voltages across each supercapacitor and limits the maximum voltage of each supercapacitor to a predetermined value. Its adjustable input current limit function enables operation from a current limited source, while prioritising system load current over battery charge current. An external disconnect switch isolates the primary input supply from the system during backup.

The device also includes input current monitoring, an input power fail indicator, and a system power fail indicator. The LTC4041 also includes an optional OVP (over-voltage protection) function using an external MOSFET that can protect the IC from input voltages greater than 60 V.

For power supply designers of thermally- and space-constrained medical systems, it is important to have a compact and efficient 5 V buck converter that has high conversion efficiency to minimise thermal constraints and a very small solution footprint and height profile.

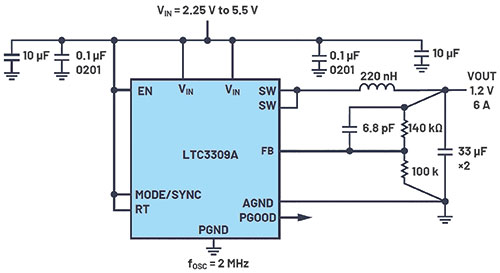

The LTC3309A specifically addresses space and thermal design constraints. It is a very small, low-noise, monolithic, step-down DC-DC converter capable of providing up to 6 A of output current from a 2,25 V to 5,5 V input supply. The device employs ‘Silent Switcher’ architecture with external hot loop bypass capacitors to achieve both low EMI and high efficiency at switching frequencies as high as 3 MHz.

Moreover, the LTC3309A is a constant frequency, current-mode, step-down DC-DC converter. An oscillator turns on the internal top power switch at the beginning of each clock cycle. Current in the inductor increases until the top switch current comparator trips and turns off the top power switch. The peak inductor current at which the top switch turns off is controlled by the voltage on the ITH node.

The error amplifier serves the ITH node by comparing the voltage on the FB pin with an internal 500 mV reference. When the load current increases, it causes a reduction in the feedback voltage relative to the reference, leading the error amplifier to raise the ITH voltage until the average inductor current matches the new load current. When the top power switch turns off, the synchronous power switch turns on until the next clock cycle begins or, in pulse-skipping mode, inductor current falls to zero.

If overload conditions result in excessive current flowing through the bottom switch, the next clock cycle will be delayed until switch current returns to a safe level. If the EN pin is low, the LTC3309A is shut down and is in a low quiescent current state. When the EN pin is above its threshold, the switching regulator will be enabled.

Since the LTC3309A uses a constant-frequency, peak current-mode control architecture, it can provide fast transient response with minimal output capacitance. A 500 mV reference allows for low-voltage outputs, while 100% duty cycle operation delivers low dropout.

Other features include a power good signal when the output is in regulation, precision enable threshold, output over-voltage protection, thermal shutdown, a temperature monitor, clock synchronisation, mode selection, and output short-circuit protection. The device is available in a compact 12-lead, 2 mm x 2 mm LQFN package.

Conclusion

There can be no doubt that the system designers of portable and wireless medical monitoring devices used for in-home patient health monitoring purposes face daunting design challenges. These include the multiple constraints that they must accommodate, many of which seem to be mutually exclusive. Examples are both thermally- and space-constrained enclosures, as well as being able to transmit data without interference or interruption.

Fortunately, thanks to Analog Devices’ recent introductions of the LTC3309A and LTC4041, the designer has viable solutions to meet the demands for small, compact, and thermally efficient solutions that will fit into portable equipment form factors.

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

© Technews Publishing (Pty) Ltd | All Rights Reserved