In the early days of fibre communication, distance was important and voice communication was the number one consideration.

Today speed plays a pivotal role and fibre is used for voice and petabytes of data information, which includes audio, broadband Internet, video on demand, live streaming services and many more.

Fujikura Ltd., a Japanese company, was founded in February 1885 by Zenpachi Fujikura. The company started by manufacturing silk and cotton insulated winding electrical wires. Since then, Fujikura has grown to an industrial giant with over 50 000 employees and clocking over $7 billion per annum and has become one of the largest cable manufacturers in the world. Fujikura developed the first arc fusion splice machine in 1978 and the world’s first core-alignment unit in 1985.

With the advent of optical fibre cables, one of the challenges that presented itself was the joining of two fibres. The first technology available to join the fibres was mechanical splices, which used a connecting jelly in a casing; however, these types of connections were not suitable for long distance transmission.

A new method had to be found to join the fibres in a way that minimised transmission loss and to be more permanent and stable. In 1978 Fujikura developed the first arc fusion splice machine, the Fujikura FR-1. The unit was comprised of an electromechanical component and a microscope.

By 1980 Single Mode (SM) fibres were developed and in 1985 Fujikura launched the world’s first fully automated arc fusion splicing machine, the F-20 Series. This was the first splicer to use the Fujikura Profile Alignment System (PAS), now common in all modern splicing machines. The FSM-20CS was recognised worldwide as being excellent and was put into mass production that moved Fujikura into the No. 1 world market position. Today, four decades later, Fujikura still remains the world leader in splice equipment.

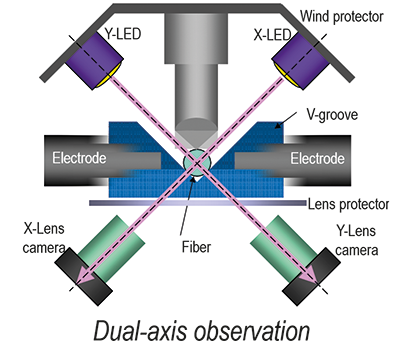

PAS is the intelligent recognition of the core of the fibre. The splicer detects the refraction of light caused at the core-cladding interface. Images are taken in two orthogonal planes so that the core can be located precisely. The unit uses six high-precision stepping motors to align the fibre on the X axis and Y axis. The camera focus point on the fibre is also adjusted. PAS information is also used to determine the fibre-type, i.e., SM, MM, DS, NZ or BIF.

In just microseconds, the splicer reads the cleave angle at the edges of the fibre and checks for foreign anomalies like dust or moisture and does a cleaning arc to remove them. The final splice-arc is at 8000 V d.c. across two electrodes and is carefully controlled by a very sophisticated (secret) algorithm which sets the arc frequency, arc power and duration. Stepping motors move the fibre in whilst the unit arcs and a perfect joint is achieved.

Environmental information, i.e., temperature, humidity and altitude, is used before and during the splice arc to automatically adjust the algorithm. Any adjustments are stored and used for the next arc. This keeps the Fujikura splicer accurate even if environmental changes occur.

Lastly, a tensile strength test and automated checks are done to detect weakness or anomalies in the joint and a Splice Loss Estimation (SLE) is done. SLE is the process used within the splicer to gauge the amount of optical power lost at the splice joint. Traditionally, field splicers have utilised only cold images for loss estimation and as a result, splice loss evaluation was much simpler. Fujikura uses warm splice images (Core-Sense technology) to increase accuracy. This increased estimation accuracy gives operators a better tool to gauge the quality of their splice before wasting time testing and performing splicing rework. Whereas before it was a mystery as to what your actual splice loss would be with a splice joint, you now have confidence of an accurate reading.

Fujikura currently offers two types of splicing machine technologies: 1) true core-alignment for backbone (Fujikura-90S); and 2) cladding-alignment for FTTX (Fujikura-41S). These units are fully ruggedised for shock, moisture and dust resistance and suitable to operate in harsh conditions.

Fujikura’s smart management technology includes Active Blade Management Technology (ABMT) and Active Fusion Control Technology (AFCT). ABMT utilises Bluetooth communication with the CT50 cleaver to manage cleaver blade rotation when the blade is worn. AFCT features True Core Alignment via Advanced Image Processing Technology (AIPT) which is a type of AI (artificial intelligence) technology to enhance splice quality under all conditions.

The combination of both technologies provides stable low-loss splicing.

Fujikura splice kits feature user friendly operation, ultimate robustness, smart management technology, new concept electrodes, universal tube heater, carry case, removable work tray, easy maintenance and fully automated 4-step splicing with dual heater oven-element on the 90S.

IC Logistix (ICL) is the sole accredited distributor for Fujikura in southern Africa. ICL was founded in 2011 when an opportunity opened up to attain the distribution rights for Fujikura Ltd. Customers hold ICL in high regard for its professional service, highly knowledgeable staff who are keen to assist and for its integrity – a rare characteristic in this day and age.

Aftersales service

WARNING: Some ruthless distributors offer equipment without aftersales service. An unenlightened client might purchase often cheap, nasty and inferior equipment without realising that no aftersales service is available in South Africa.

ICL offers in-house service, calibration and repairs at its accredited lab in Ferndale, South Africa. The lab is fully accredited for the Fujikura, AFL and Softing brands and ICL’s technical staff are factory trained and specialised in their respective fields.

IC Logistix carries a vast amount of spare parts for all models and even serious repairs are usually completed within a 3-day turnaround time. All the company’s products are imported via the correct channels and carry the manufacturers’ warranty as specified.

Contact IC Logistix for more information at

| Tel: | +27 11 521 2370 |

| Email: | [email protected] |

| www: | www.iclogistix.co.za |

| Articles: | More information and articles about IC Logistix |

© Technews Publishing (Pty) Ltd | All Rights Reserved