Thermal management and temperature derating have always been something that designers have had to plan for to keep their products safe. Temperature and power are closely linked, especially when it comes to connectors.

Every electrical circuit has resistance. The value may be small, but when passing power through that circuit, any resistance causes some of the energy to be converted into heat. With enough power, this can cause a rise in the temperature of the terminal, which is transferred to everything else around it.

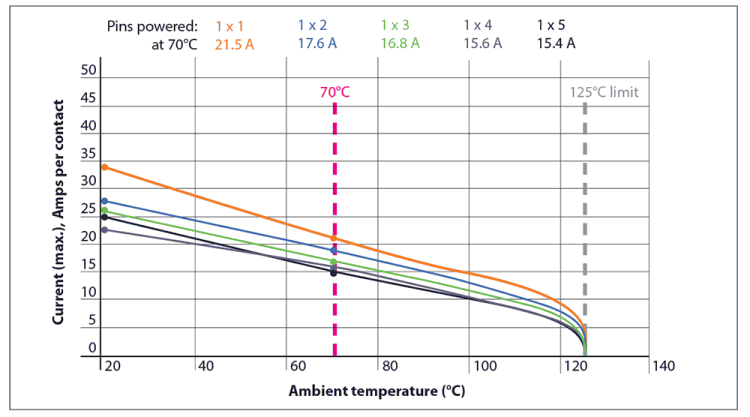

For this reason, it is important to understand how much heat is generated. In common with many connector manufacturers, Samtec publishes a temperature derating chart, in particular for the power connectors. Figure 1 shows an example chart, taken from the popular mPOWER series of power connectors. In the chart, it can be seen that an ambient temperature of 70°C requires that the current passing through the contact be reduced by 20%, proving that external conditions play an important role in the performance of connectors.

The published operating temperature of the connector itself also needs to be considered. This will often be limited by the materials used in the connector’s design, in particular the plastic used for the insulator. In the hypothetical example, the operating temperature range of the connector might be 125°C which is typical for a Samtec connector fitted with gold-plated contacts. Samtec also manufactures connectors with tin-plated contacts as a more cost-effective option, but it is important to note that the operating temperature for tin-plated contacts is lower.

There are several solutions to the problem of temperature and current ratings. The simplest approach is to use a connector with larger contacts. One of the key factors governing the current rating of an electrical terminal is its mass. A larger terminal with more material should have a lower resistance and be able to carry more power. However, as the goal is to find solutions for the compact designs of the future, a larger connector is not always convenient.

A second method to solve the problem is to use a connector with a larger pitch. Pitch is the term used to describe the distance between terminals within electrical and electronic components. A greater pitch will aid in the dissipation of heat, which should lead to a reduced temperature rise for a given current. However, this solution will also result in a larger connector, which does not solve the initial design problem.

The thoughtful approach is to consider the contacts themselves. Conventional designs comprise a fixed male contact that is inserted into a female socket. The mating area of the female terminal is split or bifurcated, and the two parts provide a constant force to ensure electrical continuity. The actual area of contact between the two terminals is small. However, alternative contact designs allow greater performance.

Samtec offers connectors with a range of contact designs that allows the correct choice of connector for the intended application. Regardless of the choice that is made when selecting power connectors, it is vital that the concept of how the environment will affect the design is understood. To aid in the design choices, Samtec offers a range of information, including temperature derating charts, that allows for an informed decision to be made.

| Tel: | +27 11 425 1400 |

| Email: | [email protected] |

| www: | www.spectrumconcepts.co.za |

| Articles: | More information and articles about Spectrum Concepts |

© Technews Publishing (Pty) Ltd | All Rights Reserved