Transmitting electrical energy over long distances, for example, inside a factory, is no easy task. Of course, electricians could provide a connection to the power grid at any location in a manufacturing facility. However, this is time-consuming and expensive.

Power over Ethernet (PoE) has existed as an alternative to individual power grid connections for many years. With it, up to 71 W can be delivered to a device (at up to 100 m). PoE uses Cat 5 and higher twisted pair cables, and is employed in numerous applications in which Ethernet cables have already been installed.

A type of PoE called SPoE, also for two-wire cables, represents a new option. With it, up to 52 W can be transmitted via a single two-wire cable. Distances of up to 1 km are possible. Two-wire cables are already being used in many industrial plants for 4 to 20 mA applications. They can easily be used for SPoE. If there’s no existing wiring, new wiring can be added easily, even without the help of an electrician.

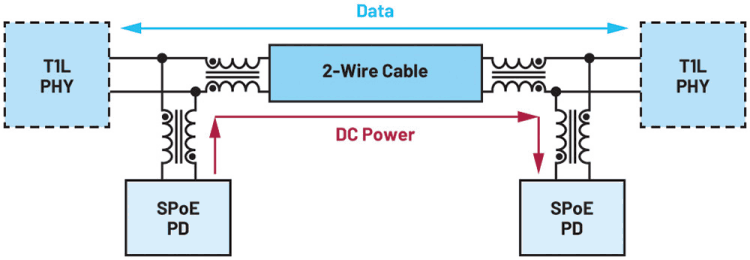

Like PoE, SPoE can be used for both data and power transmission. This is significant, because remote electronics usually need power and data connectivity. Figure 1 shows this with the T1L PHY blocks.

Why would you use the SPoE technology to transmit just energy? SPoE is an IEEE-standardised technology that is compatible with SPoE hardware from a variety of different manufacturers, provides comprehensive system telemetry for monitoring the energy transmission state, detects faults, and offers overvoltage protection and ground loop isolation.

An SPoE solution requires a power sourcing equipment (PSE) controller, that is, a circuit that transmits the electrical energy through the two-wire cable, and a powered device (PD) controller that receives the energy from the two-wire cable. Figure 1 shows a point-to-point connection. Star and daisy-chain connections are also possible. If existing cables are used, this reduces the cost and effort required to rewire the circuitry.

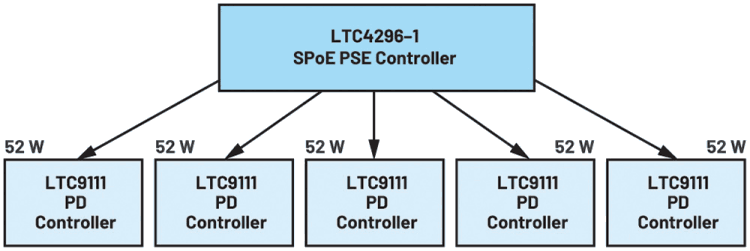

PSE controllers are often designed for multiple channels (cables). This is significant for systems that power multiple remote machinery (that is, sensors). The LTC4296-1 from Analog Devices, for example, can supply up to five loads of energy (Figure 2). Each supply line can be up to 1000 m long.

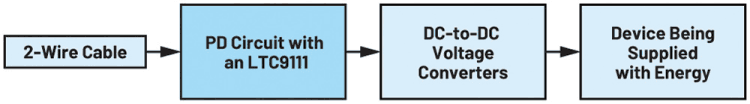

Figure 3 shows a block diagram of a PD receiver circuit with an LTC9111. The energy comes from the two-wire cable. The PD circuit takes care of the classification and monitoring of the line transmission, with the classification specifying the power class that the energy transmission will operate in. If the operated electrical device needs a voltage other than 24 or 55 V, an additional DC-to-DC converter is used.

Another technology besides SPoE is power over data line (PoDL). The two technologies are very similar. SPoE works with a voltage of 24 or 55 V and can bridge distances of up to 1000 m, while PoDL is used in systems at a shorter distance of 15 or 40 m and works with a voltage of 12, 24, or 48 V. PoDL is mainly used in automotive and similar applications, such as construction equipment. SPoE is designed for use in industrial environments.

There are clever ways of delivering power safely through a two-wire pair cable. This makes high-power applications, like intelligence at the edge, possible and reduces costs by using wiring from existing industrial setups.

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

© Technews Publishing (Pty) Ltd | All Rights Reserved