Bidirectional, power-dense DC–DC converters are the ideal solution for the new and challenging use cases presented by machine electrification across numerous industries. High-efficiency, fixed-ratio DC–DC converter modules can support transient regenerative loads without the cost and complexity of liquid cooling.

Electrification, the societal movement away from fossil fuel powered machines, is sweeping across all industrial, vehicle and aerospace/defence equipment categories. Electrification has both environmental benefits and key performance benefits such as high-torque motors enabling high levels of acceleration in electric vehicles.

High DC voltages ranging from 270 V up to 1000 V are commonly used in electric equipment and vehicles to reduce power losses in the bussing or cabling between the power source and the load. High voltages also enable the delivery of high levels of transduced mechanical force, both linear displacement and rotational displacement.

DC–DC converters play a vital role in transforming high voltages to lower voltages, with or without isolation, regulation, and reverse operation, in electric vehicles, data centres, communications systems, and industrial equipment. These power converters can be implemented using discrete components or in modular package form.

Over the past 10 years or so, the dominant DC subsystem power delivery network (PDN) voltage of 12 V has begun to transition to 48 V (54 V in data centres), driven by the significant increase in load power requirements, and the need to maintain safety, heralding the emergence of HV-to-48 V DC converters. Coincident with this evolutionary change of subsystem PDN voltage has been the adoption of 48 V-centric DC-DC converter power modules, which have numerous ease-of-use, power density, power scaling, and weight benefits, and which support regeneration.

Electrolytic batteries, using a fast-evolving variety of chemistries, are often used as both high-voltage and low-voltage DC power sources and are obviously ideal for mobile and handheld applications. The rechargeable nature of many battery types, from lead acid cells to the latest sodium-ion and graphene types, and modern supercapacitors, support regenerative energy use cases that in aggregate are destined to save enormous amounts of energy globally.

In electric vehicles, it is common to see nominal battery pack voltages of 400 and 800 V DC, with 800 V battery packs likely to dominate. Mild hybrid vehicles generally use 48 V DC batteries, with some manufacturers electing to use 12 V DC multi-cell packs. Electric vehicles include not only automobiles, but also industrial and agricultural vehicles and all types of recreational vehicle platforms.

Why is 48 V DC power distribution replacing 12 V DC power distribution?

Higher distribution voltage delivers the same power with lower current. Because distribution power losses are a function of the square of the current (P = I2R), in high power applications these substantial conduction losses due to busbar and cable resistance can be reduced by using higher distribution voltages.

Busbars and cables are sized according to current carrying capacity, and a 4x increase in voltage and a 4x decrease in current has a substantial impact on sizing, weight, and cost. For example, to conduct 200 A, a copper busbar needs a cross-sectional area of about 0,4 square cm, whereas to conduct 800 A, a copper busbar needs a cross-sectional square of about 2 square cm, five times larger.

High voltage to 48 V conversion with a fixed-ratio converter module

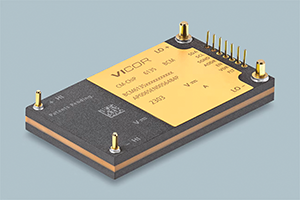

The Vicor BCM6135 series is a family of fixed-ratio, isolated, bus converter power modules with integrated magnetics and by design are inherently bidirectional, supporting regenerative battery applications.

One member of this family, a 2,5 kW steady-state-rated module, has a ratiometric conversion ‘K factor’ (the equivalent of transformer turns ratio) of 1/16 and is rated to convert nominal 800 V to nominal 50 V. Due to its circuit topology and zero-voltage and zero-current switching, its peak efficiency is 97,3%, resulting in only 67,5 W of power loss as heat.

The BCM6135 supports instantaneous bidirectional start-up and steady-state operation. Furthermore, the BCM6135 acts as a capacitance multiplier, scaling the bulk capacitance across the high-voltage bus to the low-voltage bus by the square of the K factor. This attribute saves the cost, weight, and space of the bypass or bulk capacitors that otherwise would be required on the low-voltage bus.

Additionally, the high switching frequency of the BCM enables extremely fast load step transient performance of 8 MA/s, allowing the module to replace auxiliary batteries and supercapacitors otherwise needed to support the transient load steps in demanding applications.

The thin 7,3 mm BCM6135 module family is overmolded and electroplated for thermal agility, shielded and interconnected through surface mount terminals or through-hole pins, and the three-dimensionally interconnected ChiP package offers low thermal impedance and high thermal adeptness, including a coplanar thermal interface to heat sinks and cold plates.

This high-voltage to 48 V power module is often used in continuous load applications, but it is also well suited to transient pulse load applications and depending on the pulse duty cycle of the load, potentially can be used with passive cooling.

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

© Technews Publishing (Pty) Ltd | All Rights Reserved