Wide input rails are common in many electronic systems including communications infrastructure, automotive and industrial systems. Input voltages as high as 100 V need to be converted to 24 V/12 V/5 V or other lower voltages that can be used by electronic systems.

A typical solution for creating one or more low-voltage rails consists of a low-voltage integrated controller with additional drivers, FETs and sometimes transformers. A high step-down ratio sometimes involves more than one power stage.

Increasingly, wide input voltage power management integrated circuits (ICs) that combine features previously available only at lower voltages are now available from many vendors at competitive prices. High-voltage power management ICs, such as Texas Instruments’ LM5000 series of integrated controllers and regulators, can simplify the design of high-voltage power management solutions.

This article presents various application scenarios where high-voltage capability up to 100 V is required, and explains how high-voltage power management ICs can reduce component count, enhance reliability and facilitate design reuse. Real-world circuit examples from communication infrastructure, industrial, automotive and consumer electronic systems demonstrate the potential benefits.

Operating voltage ratings

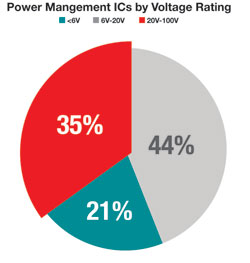

Power management ICs are available in various voltage ratings and have been available in lower voltage ratings for some time. Each new generation increases integration and drives down cost.

Major analog vendors are building high-voltage custom processes where multiple voltage ratings can be achieved in the same process. Using different doping concentrations and clearance, more integrated features are becoming available at higher input voltages and at a competitive price.

Motivations for using wide VIN voltage integrated ICs

More than 35% of power management ICs currently in use handle an input range above 20 V and wide input voltage range is common in industrial, automotive and communications infrastructure systems. Even for many 12 V and 24 V systems, transient conditions approaching 100 V are not uncommon and need to be considered.

Systems that require high voltage (up to 100 V) fall in three groups: 1) those that must operate at high input voltages; 2) those that need to be protected against high input voltages; and 3) many where the high voltage is desired for extra margin of safety and system robustness.

The first group consists of systems that need to operate properly at high input voltages (40 V – 100 V). Examples of high-voltage systems include Power over Ethernet (POE) line range of 37 V – 57 V, and a 48 V communication bus with a range of 36 V – 75 V. This is where high-voltage ICs have maximum impact.

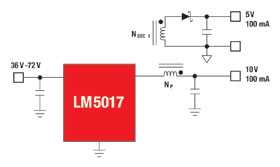

High-voltage ICs replace multiple discrete elements, and sometimes transformers that characterise the non-isolated supplies operating from high voltage. One example circuit operating from a 36 V – 72 V line voltage is shown in Figure 2. The lower output voltage is used by driver and controller circuits.

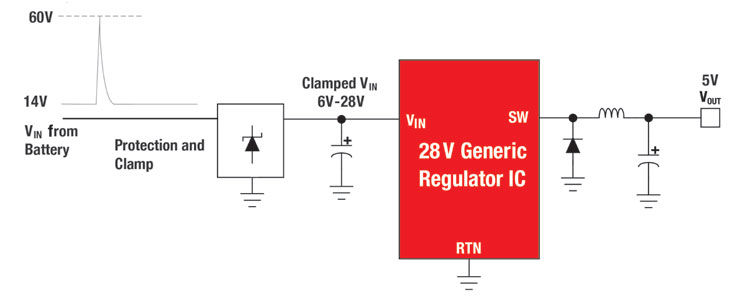

The second group of applications typically operate from a fixed lower voltage rail, for example a 12 V or 24 V battery, such as in automotive (or truck) systems and industrial systems. Occasionally, however, the input line has spikes of 60 V or higher.

While the power management circuit is not supposed to operate and deliver power to its full capacity at these abnormally high voltages, it is nonetheless expected not to fail or expose the downstream circuits to unsafe voltages. Many of the ICs targeted for 12 V/24 V rails are rated for 20 V or 28 V. To protect these devices from higher voltage surges, usually some kind of protective clamp is used that limits the input voltage spikes to a level below the rated voltage.

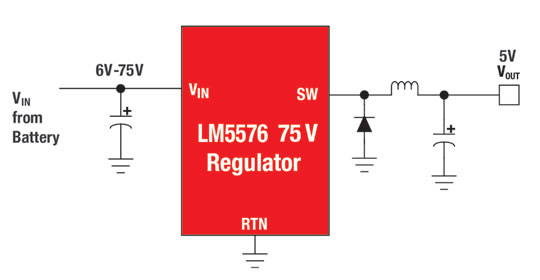

Figure 3a shows a 12 V system with input clamp. These clamps add cost, area and design time. A high-voltage IC, such as the LM5576, can provide seamless operation throughout the input voltage transient without requiring a low-voltage clamp protection circuit (Figure 3b).

For higher-current applications, high-voltage controller ICs, such as LM5116-19, provide advanced features which include fixed frequency pulse-width modulation (PWM) operation with external sync, buck-boost operation (LM5118) and multi-channel operation (LM5119).

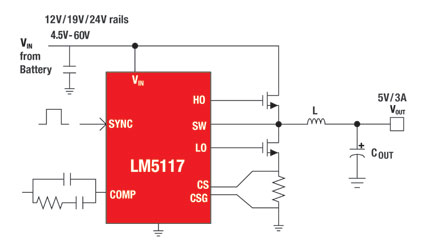

A 3A buck converter for USB chargers is shown in Figure 3c. This buck converter can operate directly from 12 V/24 V automotive rails or 19 V laptop charger ports.

Finally, there is a third group of applications for when the designer wants an extra margin of safety and robustness. Even though a lower-voltage power management solution may work in theory, there are those uncharacterised conditions that may happen only once in the lifetime of the product.

Using a high-voltage integrated circuit that is just as easy to use as its low-voltage counterpart provides the designer peace of mind. The product now has an extra level of reliability that may make the defining difference in the quality of otherwise comparable products.

Power semiconductor devices are particularly sensitive to over-voltage. This is because the devices’ operating and absolute maximum voltage ratings tend to be very close. Because of this, any design margin needed for a robust design must be considered by the designer when selecting power management ICs and passive components.

Once a DC-DC controller or regulator with sufficient voltage margin has been selected, a lot of flexibility in design is available to the designer, as is explained in the rest of this article.

Design reuse using wide VIN power management ICs

Many designers tend to re-use a proven circuit with minor modifications for multiple input/output rails. This approach allows them to save significant effort when a new circuit is designed and debugged from scratch.

The designer knows from experience the tricks, traps and capabilities of an existing circuit. Additionally, the component selection, layout and inventory management are simplified by reusing one building block instead of creating separate building blocks for each rail in the system.

Certain arguments can be made in favour of selecting a more customised IC that is especially suited for a lower-voltage application. Chief among these are the lower resistance associated with low-voltage integrated devices, lower cost and possibly extra features.

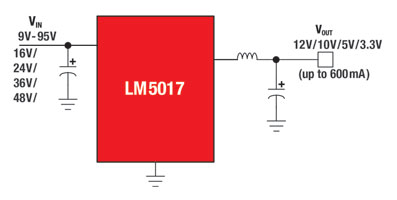

For low-current, lower-power applications, the benefits of having a common pool of converter and regulator circuits usually outweighs the incremental improvement in performance offered by the lower-voltage counterparts. This is truer now with the availability of high-voltage integrated regulators that come at a competitive cost. One such example is shown in Figure 4.

A standard constant on-time (COT) synchronous buck regulator circuit like the LM5017 can be used in multiple applications having different input and output rails. Repeated use saves both design and debug time.

Another scenario is presented in the system shown in Figure 5. The first stage converts from 19 V – 38 V rails to a 16 V rail, which is used for certain parts of the circuit. The second stage converts the 16 V rail to a 3,3 V rail. Using the same circuit as the starting point for both regulators reduces the effort in designing the overall power solution.

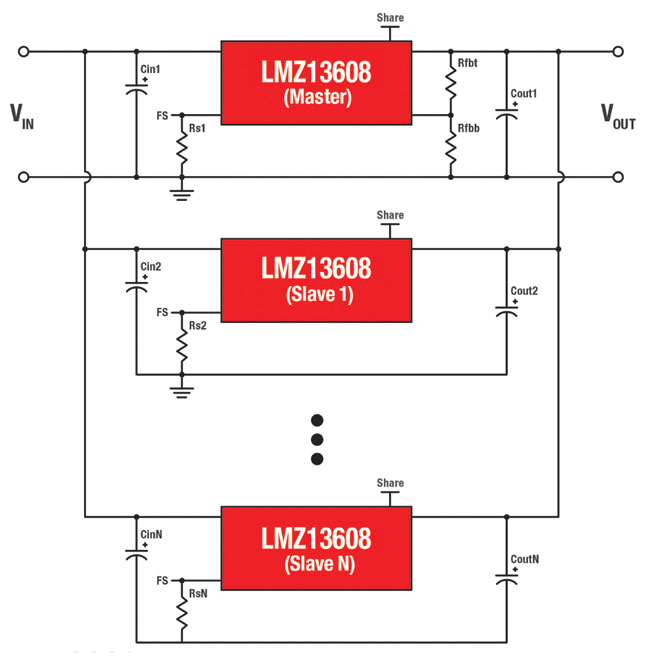

The solution in Figure 6 uses up to six LMZ13608 modules in parallel to achieve a high-density 36 V input power supply for up to 48 A output current.

Inverting rails using wide VIN ICs

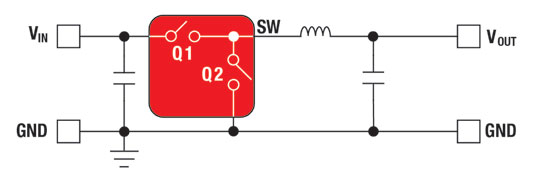

Another area where high-voltage ICs can save the day is in generating negative voltage. It is common knowledge that a buck regulator IC can be used in an inverting buck-boost configuration to generate negative output rails from positive input voltage rails.

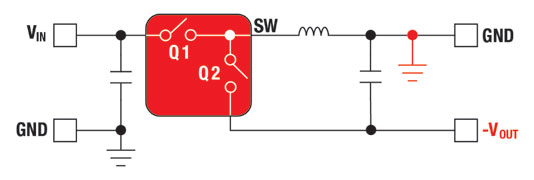

On closer inspection, when used in an inverting buck-boost configuration, one discovers that the regulator ‘sees’ a voltage equal to the sum of input and output voltage (VIN+VOUT) across its positive and return terminals. This is illustrated in Figure 7.

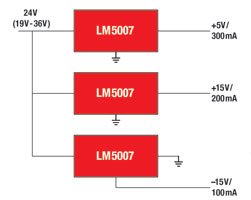

An application example is shown in Figure 8 where a +24 V rail is being converted to three different rails at 5 V, 15 V and –15 V. The LM5007, a high-voltage, step-down switching buck regulator IC, is being used to generate each of these rails. The –15 V output is generated by using the LM5007 in the inverting buck-boost configuration. Although the input and output voltages are 24 V and 15 V respectively, the voltage across the regulator terminals is (24 V + 15 V) = 39 V.

Even a 40 V IC leaves very little design margin when utilised in this configuration. But since the LM5007 is rated for 75 V, it provides sufficient design margin for transient spikes and input voltage variations. As outlined earlier, the designer saves time and cost by using one high-voltage IC and a common BOM for all three rails.

Summary

With advances in high-voltage semiconductor devices, integrated power management ICs such as DC-DC controllers and regulators are now available from multiple analog companies. These integrated devices, such as the LM5000 series of high-voltage controllers and regulators, make it easy to create power management solutions that can operate or withstand up to 100 V on the input rails.

The high-voltage capability eliminates the cost and effort associated with designing input voltage clamping circuits needed when using lower-voltage devices. Additionally, the high voltage rating provides extra design margin, robustness and reliability in devices operating from 12 V and 24 V systems.

Using higher-voltage devices allows designers to save time and effort by allowing reuse of a design or nearly identical designs for many different input and output voltage rails, thereby eliminating the need to work with multiple stages or multiple circuits.

For more information contact Erich Nast, Avnet Kopp, +27 (0)11 319 8600, [email protected], www.avnet.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved