The trend toward e-mobility is finally gaining traction in the market, as more and more vehicles of all kinds are being outfitted with energy efficient and zero emission drives.

Besides cars, they include smaller utility vehicles used in municipal services, construction and agriculture, and industrial trucks such as electric forklift trucks, automated factory floor vehicles and more.

As a result, the need for compact, lightweight and high-performance drives in these vehicles is growing.

Innovative inverter design

In response to this demand, Scienlab electronic systems, a specialist for power electronic designs based in Bochum, Germany, has developed a compact inverter (2 dm³), which has a power rating of 40 kW and can support operating voltages of 290 V d.c. to 420 V d.c., making it suitable for a wide range of applications such as those mentioned above. The inverter’s hardware and software structures enable a very dynamic range of output currents and, as a result, very dynamic vehicle performance.

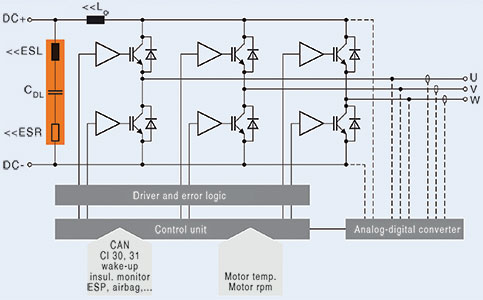

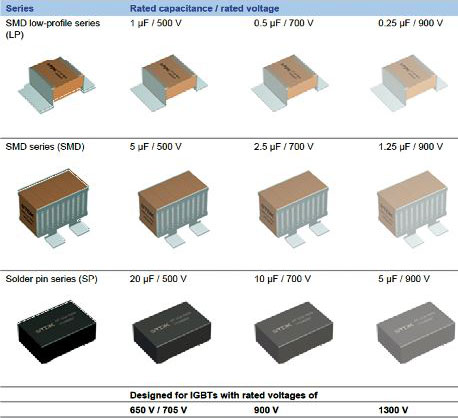

The design of the traction inverter has four main functional units: the control circuit, driver, the power electronics, and the robust housing and connections. The inverter features an IGBT module with a fully controlled three-phase bridge circuit (B6C), while the DC link features innovative CeraLink capacitors as a key enabler (Figure 1).

The modular design makes the inverter very scalable to customer-specific current and power requirements. For example, a higher power IGBT module can be used with minimal adaptations to the driver PCB. The self-contained DC link circuit board can also be easily expanded simply by increasing the number of CeraLink capacitors. All the while, no change is necessary for the control circuit. Moreover, the inverter’s software, which resides in a controller for automotive applications, was created with a toolchain. This adaptive development process enables customer-specific software adaptations without necessitating major changes to the software structure.

Inverter requirements

In order to make the inverter suitable for automotive e-mobility applications, the new design had to employ only automotive qualified components. It also had to offer a very high power density, in order to make it as compact and lightweight as possible. To meet these requirements, Scienlab used a water-cooled IGBT with a small power semiconductor chip surface area.

The configuration of the controller and driver circuit boards was also optimised to save space. Scienlab, however, focused much attention on the volume and performance of the DC link as one of the largest sections of the inverter.

Compact and flexible DC link

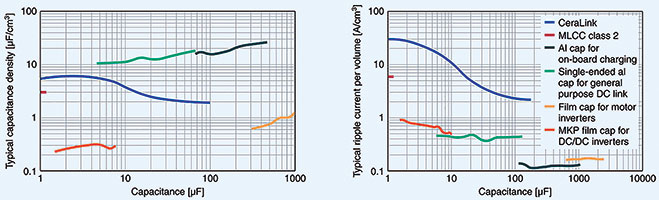

For the DC link Scienlab selected TDK’s CeraLink capacitors, which feature a very high capacitance density of up to 5,5 μF/cm³ (Figure 2).

“Compared to other capacitor technologies, CeraLink offers the best combination of capacitance density and ripple current capability,” explains Dr. Christoph Doerlemann, managing director of Scienlab. This enables compact packages without sacrificing any performance in the DC link. “And this is where our traction inverter sets itself apart from other inverters,” he says. Altogether, the inverter employs 36 CeraLink capacitors with a capacitance of 5 μF each, which are connected in parallel to achieve a total capacitance of 180 μF.

These new capacitors are based on the ceramic material PLZT (lead lanthanum zirconate titanate). In contrast to conventional ceramic capacitors, CeraLink capacitors reach their maximum capacitance at the application voltage, and this even increases proportionately to the share of the ripple voltage. Thanks to the compact CeraLink capacitors it was possible to reduce the volume of the DC link by a factor of three to four (compared to a design with conventional capacitors).

The capacitors are designed for an operating temperature of -40°C to +125°C and can even withstand brief exposures to 150°C. The use of many discrete capacitors not only lends greater flexibility with regard to the layout of the components, it also maximises the surface area of the capacitors and the thermal dissipation. This enables the use of passive cooling techniques, even at high ambient temperatures.

Eliminating ESR and ESL

A further design goal of Scienlab was to eliminate both ESR and ESL in the DC link. “Thanks to CeraLink’s extremely low ESL of only 2,5 nH, it was possible to drastically reduce overshoot and ringing during switching of the IGBTs, thus significantly improving the system performance of the inverter,” says Doerlemann.

In addition, Scienlab employs a specially developed multilayer PCB to connect the capacitors in parallel with very low impedance. The ESR value is just 3 mΩ at 1 MHz, which helps to significantly reduce power losses in the DC link and the resulting heat generation. In fact, the ESR decreases with increasing frequency and temperature which allows efficient operation at high temperatures up to 150°C and high switching frequencies.

| Tel: | +27 11 458 9000 |

| Email: | [email protected] |

| www: | www.electrocomp.co.za |

| Articles: | More information and articles about Electrocomp |

© Technews Publishing (Pty) Ltd | All Rights Reserved