Faulty procedures or inadequate charging equipment result in shortened battery life and unsatisfactory performance. The selection of suitable charging circuits and methods is as important as choosing the right battery for the application.

There are four most common charging methods:

• Constant voltage.

• Constant current.

• Taper current.

• Two-step constant voltage.

The constant voltage charging method is recommended for charging Forbatt batteries. Depending on the application, batteries may be charged either on a continuous or non-continuous basis. In applications where standby power is required to operate when the AC power has been cut off, continuous charging is recommended. Non-continuous charging is used primarily with portable equipment where charging on an intermittent basis is appropriate.

The constant voltage charge method applies a constant voltage to the battery and limits the initial charge current. This charging method can be used for both cycle use and standby applications, but it is necessary to set the charging voltage according to specified charge and temperature characteristics. Inaccurate voltage settings will cause overcharging or undercharging.

The charge voltage of the battery decreases with increasing temperature and vice versa. Therefore, charging with a given voltage requires an increased charge current when the temperature is high and decreased charge current at a lower temperature. It is recommended that batteries be charged at an ambient temperature between 5°C and 35°C to prevent any adverse effects on its effective life.

Temperature effects must be considered when designing or selecting a charging system. Temperature compensation might not be necessary when the battery is charged in an operating temperature range of 5°C to 35°C. However, at temperatures below 5°C or above 35°C, temperature compensation for charging voltage is necessary. The temperature coefficient for cycle service should be -5 mV/°C per cell, and for standby use (trickle charge or float charge) it should be -3,3 mV/°C per cell.

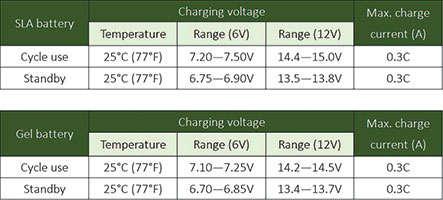

To prevent a poor charge under low temperatures and overcharge under high temperatures, the charging voltage must be set at the appropriate value according to the battery temperature. Table 1 shows the charging voltage of Forbatt’s valve regulated lead-acid (VRLA) batteries of both gel and sealed lead-acid (SLA) types.

Charging precautions

At high temperatures, the charging voltage should be higher than the open circuit voltage, while at low temperatures the charging voltage must be less than 2,35 V/cell to prevent gas being generated. It is important to bear in mind that battery life will decrease with increasing temperature, and batteries should not be stored at an ambient temperature of higher than 40°C.

For cycle use, which requires charging to be completed within a short period, caution is advised, particularly for an individual who is not familiar with the battery or charger. It is recommended to use protective measures or incorporate a backup timer to prevent overcharging, especially when applying a rapid charge. One should take safety precautions, such as an automatic cutoff upon completion, or preventing overcharging even after an extended charge by controlling the charge current.

For standby use, a trickle or float charge is ideal. In either case, the battery is normally charged at a small current to compensate for the self-discharge of the battery. Supplying power from the battery is only used in emergencies, for example power failure, and it requires a lot of time for charging. However, the two-step constant voltage charging method is recommended if the battery needs to be recovered within a short period after discharge. Because the battery is charging continuously for a long period of time, even a slight fluctuation in the charging voltage results in a big difference in the expected service life of the battery. It is essential to ensure accurate control to minimise charging voltage fluctuations.

For both cycle use and standby use, the charging characteristic is affected by temperature. A temperature compensation circuit must be used when charging is to be performed at an ambient temperature of less than 5°C or more than 35°C, and an average temperature above 25°C.

For more information contact Forbatt SA, +27 (0)11 469 3598, [email protected], www.forbatt.co

© Technews Publishing (Pty) Ltd | All Rights Reserved