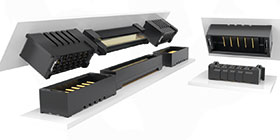

Samtec débuts compact mPOWER connector series

30 April 2019

Interconnection

Samtec’s new mPOWER connectors offer enhanced space savings and design flexibility. This 2,00 mm pitch system (UMPT/UMPS) can pass 21 A per blade while freeing up the board for other components or minimising package size.

mPOWER can be used as a standalone high-power solution, or alongside one of Samtec’s high-speed connector systems for a two-piece power and signal/ground solution. Compatible Samtec high-speed systems include: AcceleRate HD, Edge Rate, SEARAY, SEARAY 0,80 mm, LP Array, Q Strip, Q2, Tiger Eye and more.

With stack heights from 5 mm to 12 mm (up to 20 mm in development), mPOWER can be easily added to new or existing architectures. Further design flexibility is available with a choice of 2, 3, 4 and 5 power blades (up to 10 blades in development). Matte tin or 10 μ” gold plating are standard, with optional 30 μ” gold plating to meet specific regulations.

Additionally, the power blades have two-stage mating and can be selectively loaded to achieve any specific creepage and clearance requirements. Optional weld tabs provide increased stability on the board.

A variety of other options are in development for mPOWER connectors, including a right-angle version with 2 to 10 position counts, and a socket cable assembly to mate with both the vertical and right-angle terminal. The cable assembly will include latching for more rugged applications. Also in development is a 30 A system for even greater power in a small footprint.

For more information contact Quatraine Domoney, Avnet South Africa, +27 11 319 8600, [email protected], www.avnet.co.za

Further reading:

Understanding and controlling impedance in high-speed interconnects

Spectrum Concepts

Interconnection

[Sponsored] As data rates move well into the hundreds of gigabits per second, success increasingly depends on an invisible but critical factor: impedance.

Read more...

Low profile spring-loaded connectors

Spectrum Concepts

Interconnection

Mill-Max has announced the introduction of low-profile, surface mount additions to its 2 mm pitch spring-loaded connector range.

Read more...

Prefitted junction box solutions

Interconnection

Prepopulated junction boxes in popular terminal configurations, such as single- and three-phase, enhance convenience for both electrical wholesalers and contractors.

Read more...

Bulgin unveils new range of sustainable connectors

Avnet Abacus

Interconnection

The Standard Vitalis Buccaneer range of waterproof connectors is a bio-based alternative to Bulgin’s flagship series, the Standard Buccaneer, offering the same technical performance with improved sustainability.

Read more...

Possible copper cable crisis looms as global demand soars

Interconnection

With the world requiring up to 3 billion metric tons of copper by 2050 to support green energy transitions and developing nations’ infrastructure, far exceeding the 23 million metric tons mined in 2024, pressure on supply chains is mounting.

Read more...

High-reliability spring-loaded interconnects

Spectrum Concepts

Interconnection

These springs from Mill-Max are drop-in replacements for the standard springs, requiring no changes to the form or fit of the existing spring-loaded pins.

Read more...

Anoison PCB mount connectors for high-performance applications

Conical Technologies

Interconnection

With its wide selection, Anoison provides PCB mount connectors that combine precision, durability, and cost-effectiveness across industries.

Read more...

Connectors for the Smart Factory

Spectrum Concepts

Interconnection

[Sponsored] Designing networks for the smart factory can seem daunting, but the solutions are already available with Samtec providing a comprehensive range of interconnect technologies tailored to the demands of the modern factory.

Read more...

Mouser shares expert design solutions for advanced robotics development

Interconnection

Mouser Electronics has announced a new interactive eBook, ‘The Electric Workforce’, in collaboration with electronics manufacturer and connectivity innovator, Molex.

Read more...

Explosive zone connectors

Interconnection

The connector series design by Glenair is optimised for fast and easy crimp-contact wire termination, with ample wiring space in the cable housing and accessory hardware.

Read more...