In order to understand the need for surge protection, it is important to understand how lightning causes damage. The sources of lightning damage are quite different, and we use different types of mitigation techniques and equipment to protect different items.

There are two areas of concern when evaluating a building or structure, namely the structure itself, and all incoming cables, meaning IT equipment as well as power. From this, the four sources of damage are derived, as per the following possibilities:

• Having a lightning strike directly to the building, or

• Near the building, or

• Directly to an incoming line, or

• Near the incoming line.

Nearby strikes cause lightning surges. In striking neighbouring buildings, surrounding objects or areas next to incoming lines, the lightning current coming down generates a magnetic field, which is cast over the structure or lines. This magnetic field that is cast generates an induced current on the incoming line or on the cables inside the structure.

To prevent resulting damage to electrical equipment, we use surge protective devices (SPD) to reduce the induced effects of lightning. To prevent burning or mechanical damage, we attempt to avoid direct strikes to a structure by means of a system of lightning rods, also known as external lightning protection.

By installing external protection, you will protect yourself from structural damage, but this will not necessarily prevent your electronic equipment from being damaged (for example TVs, Internet routers and appliances such as kettles, fridges, microwaves and so on). Therefore, in order to protect equipment, you need surge protective devices.

The calculation from the SANS 62305-2 standard to evaluate the risks are as follows:

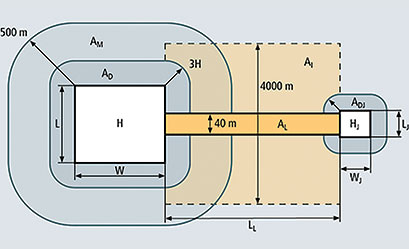

• The area to be considered for direct strikes is a radius around the structure, which is three times the height of the structure.

• The area to be considered for surges is a radius of 500 m around the structure and can be up to 2 kilometres away in both directions for incoming lines.

Referring to Figure 1, we can see that the risk of resultant surges exceeds that of direct lightning strikes, meaning that the correct installation of surge protection devices is extremely important. Other benefits of surge arrestors include the minimising of switching surges coming from the grid. This is a very relevant topic when seen against the background of recent load shedding from the South African grid.

Over the years, DEHN has developed numerous market-leading surge arrestors, with the latest offering being the new DEHNguard ACI surge protective device. This technology is a first in the market and a product of DEHN exclusively. The DEHNguard surge arrestor with ACI technology allows the user to save space, time and costs. DEHNguard is a pre-wired, complete unit that consists of a base part and plug-in protection modules. Its benefits include:

• Safe dimensioning and the elimination of mistakes: The new switch/spark gap combination is integrated directly into, and ideally adjusted to, the arrestor. A connection cross-section of just 6 mm² makes for easier installation and saves time that otherwise needs to be spent dimensioning the cross-section.

• Being able to withstand temporary over-voltages (TOV) to increase system availability and save on maintenance and repair costs. Temporary over-voltages – for example, caused by loss of neutral – can destroy conventional surge protective devices. The new ACI arrestors have a much better TOV withstand.

• Zero leakage current increases the service lifetime of arrestors. ACI arrestors also avert the accidental tripping of the insulation monitoring and contribute towards operational safety.

DEHNguard with ACI technology has recently become available in South Africa through DEHN Africa and its partners.

© Technews Publishing (Pty) Ltd | All Rights Reserved