The effects of RoHS (reduction of hazardous substances) on the electronics supply chain reach far beyond the simple yes/no question of whether equipment is lead-free. Today, the topic is technical questions; tomorrow, availability, and the day after, detailed materials disclosure.

For the electronics supply chain, this means a transparent information policy at a much higher level than before: How is EBV Elektronik approaching the problem?

Some would compare the problem presented by the new EU Directives on waste electrical and electronic equipment (WEEE) and RoHS (reduction of hazardous substances) with the Y2K problem in the computer industry. They secretly hope that the repercussions will be just as innocuous as was the case with Y2K.

Whether this will be the case is an open question - however, the fact remains that this is not a virtual problem, but a very real one, and one that nobody in the typical electronics supply chain can avoid. If one assumes that every person in charge in the industry has come to know not only the above acronym, but also its meaning and what it entails, then everything can be reduced to the following less crucial points:

1. Manufacturers of electronic equipment (exceptions can be found in the Directives) are investing millions of Euros in the area of production, in order to convert in time, to the new reduction of hazardous substances such as lead (and others).

2. They require components without these substances from the component manufacturers and distributors coinciding as closely as possible with their individual conversion date.

3. They need sufficient information on the manufacturing preparation and, later on, verification of their compliance with the RoHS Directive or with local legislation through which the Directive is implemented.

4. Although the equipment manufacturers are responsible for RoHS compliance, legal responsibility is already beginning to spread out over the whole supply chain.

The first of these points has been discussed in great detail for over a year - 'lead-free soldering' could almost be the 'phrase of the year' thanks to the huge amount of attention afforded it. However, public discussion has neglected points two and three.

It must be recognised that the reaction of the component industry, faced with the RoHS Directive and its consequences, has been extremely ill-co-ordinated, both in terms of component conversion and in them provision of necessary information. This is not malicious, but rather, reflects usual individual company behaviour. The following are some excuses:

* Europe is not the global market.

* Technical conversions cost a lot and are by no means trivial.

* A change in information policy likewise requires a great deal of money and time.

* The disclosure of data on materials also entails enormous expenditure, for which almost nobody is willing to find the resources.

* Last but not least, the need for information currently far exceeds the willingness to order new components right now.

The last point may in fact change rapidly, primarily because larger customers who have mastered the technical problems involved in production changeover, will want to start operating lead-free as quickly as possible. However, most distribution customers have yet to sound out the information situation effectively and define the right conversion date for their company.

Result: The conversion plans of equipment and component manufacturers are - naturally - not co-ordinated. The same is true for their information strategies. Large OEMs and large component manufacturers can always agree on individual solutions; unfortunately, this does not apply to the so-called mass market.

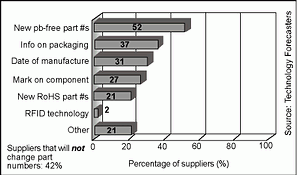

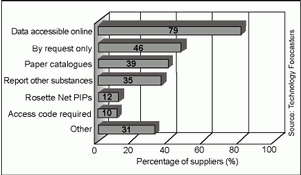

In order to sound out the information and technical situation with regard to the lead-free conversion and RoHS, Avnet Electronics Marketing, an operating group of Avnet, the parent company of EBV Elektronik, commissioned a survey from the US market research company, Technology Forecasters. The two questions posed (see Figures 1 and 2) paint an excellent picture of where the problems lie.

1. Component identification: Around half of the manufacturers surveyed are in different camps as far as the correct identification method is concerned. Should a new part number be used, or should separation of conventional and lead-free components be achieved within the scope of the old part number? However, even those manufacturers who think that a new part number should be used cannot agree.

2. Provision of information: Almost 80% of the component manufacturers provide information on lead-free conversion/RoHS on their websites. However, there is no standard format for provision of information, nor is there a clear direction in terms of the details required. Can a customer find all of the information necessary to ensure RoHS compliance on the manufacturers' websites? The answer is: Not yet.

Back to the mass market: What could previously be arranged between a large semiconductor manufacturer and a large OEM, possibly on an individual basis, now appears extremely difficult given the European distribution situation. EBV Elektronik represents a total of 18 semiconductor manufacturers and has over 13 000 customers. Each one has different plans, whether with regard to the conversion date, component identification, the exact information requirement or ensuring conformity. The situation is depicted from the distributors point of view in the diagram below.

As a distributor, you cannot escape the fact that at this time of RoHS conversion, a 100% match between manufacturer plans and customer requirements will hardly be possible. However, it is possible to adapt your own logistical, IT and information capabilities so that the customer is afforded as much help as possible.

EBV has approached the issue in three steps:

1. Clear identification of products both in the system and in the warehouse.

2. Clear and uniform communication directly with the customer throughout our business units.

3. Greatest possible support of customers in their quest to obtain information.

The first step is more technical and system-related, and is dependent on the warehouse structure. However, it has already been implemented in all of our business units. Clear identification of lead-free/RoHS-compliant products in our backbone systems is already in place as per availability of such components, and is gradually being further developed. At the Avnet warehouse in Poing, Germany (EBV Elektronik's logistical service provider), components are already separated visually, currently with a 'lead-free' sticker. This system is to be further refined in the future. In the current quarter, our delivery documents are to be changed so that our customers can see the important information on the delivery notes and other documents. Depending on the quality of manufacturer information, we intend to expand the information scope further.

The second step, currently running parallel to the first, involves constant communication with the customer. Here, in many cases, possible problems are still being sounded out - and not all regions of Europe are marching to the same beat. We have thus decided to tackle the matter with foresight rather than hindsight. This would involve our sales teams going through fairly long-term projects with customers in order to 'factor out' supply problems by planning ahead as far as possible. As another option, we offer our supply chain expertise in order to be able to identify any stock control risks for the customer. Finally, our 100+ field application specialists are always available to find solutions for product discontinuation and necessary redesign caused by RoHS.

The third step, on the other hand, is concerned with medium to long-term information policy. As soon as the customers have successfully negotiated the technical problem phase in their lead-free production, they will realise that a simple yes/no to the lead-free question does not suffice for ensuring RoHS compliance. Are we simply to hope that all suppliers of primary products - including electronic components - provide this information on time before the legislation comes into force and monitor compliance informatively and comprehensively? EBV Elektronik, in any case, has decided not to leave the achievement of such a level of information quality to the manufacturers, and is working on its own database solution with extensive information that goes far beyond whether components are lead-free. Here, we have not yet gone beyond evaluation of the precise direction. Nonetheless, it is clear that we intend to give our customers the widest possible access to this data.

Summary

The European electronics industry finds itself in, what is no doubt, the greatest conversion phase of its history. 1 July 2006 will leave its marks far beyond this date - the era of green electronic design has just begun. EBV is determined to meet the challenges involved head-on, aiming for the greatest possible customer support. However, there is one aspect where we are just as incapable as every other distributor - namely, taking legal responsibility for the compliance of products manufactured by other companies and for information that is not our own.

For more information contact Steve Stafford, EBV Electrolink, +27 (0)21 421 5350.

| Tel: | +27 11 236 1900 |

| Email: | [email protected] |

| www: | www.ebv.com |

| Articles: | More information and articles about EBV Electrolink |

© Technews Publishing (Pty) Ltd | All Rights Reserved