Energy harvesting (EH) is also known as power harvesting or energy scavenging. It is the process by which ambient energy is captured, converted into electricity and used to drive small autonomous electronic, electrical and combined devices. About 500 organisations are developing or applying energy harvesting other than photovoltaics and, in addition, most of the 650 organisations developing the new photovoltaics beyond conventional silicon have energy harvesting in their sights.

Some forms have been around for some time, such as bicycle dynamos, a form of electrodynamics, and solar cells – photovoltaics – on satellites. Now, as a much broader range of energy harvesting products hit the marketplace, we can move from the technical minutiae to commercial considerations such as paybacks.

For example, virtually all space vehicles now being launched employ gallium arsenide, germanium and other thin films together in the photovoltaics to obtain greater efficiency than conventional silicon photovoltaics can achieve. The greater efficiency and thin film construction mean less weight and size, permitting reduced launch costs or additional payloads in a satellite, for example. Boeing Spectrolab is the main supplier. However, down on earth, many other paybacks are being enjoyed.

Choices

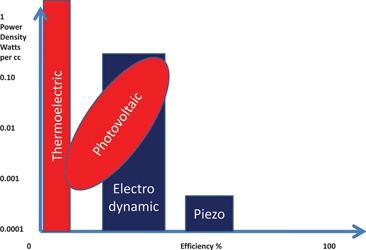

First let us look at the choices. Electro-dynamics, piezoelectrics, photovoltaics and thermoelectrics are the most popular forms of energy harvesting because they offer the best compromises of small size expressed as energy per cubic volume, ability to convert modest inputs into electricity (expressed as efficiency %), cost per watt and life.

For example, from the huge temperature differences in engines, vehicle exhausts and aircraft, thermoelectrics can sometimes produce watts per cubic centimetre and in actuators and vibration harvesters, piezoelectrics can exhibit 60% efficiency. Electrodynamics and photovoltaics exhibit a good compromise of both parameters.

Photovoltaics have a particularly wide spread of options because the shorter-lived versions such as organic OPV and dye sensitised solar cells (DSSC), while currently exhibiting only one to five years life, variously offer low cost, transparency, working with low levels of light, being tightly rollable and printable on large areas. They lend themselves to applications requiring modest life such as medical disposables, merchandising, e-labels and e-packaging.

Other versions of the new photovoltaics have excellent life of at least 20 years but are not, as yet, transparent or tightly rollable. These include printed nanosilicon, copper indium gallium diselenide and thin film cadmium telluride.

Cost criteria

The cost criteria are less demanding when one is not trying to replace power stations with less than one dollar per watt for ‘energy parity’. With energy harvesting for small devices, figures of up to 10 times as much can pay back because one is avoiding wiring in buildings or the burden of visiting millions of installed batteries to replace them. However, there is a place for batteries in some interim products such as the Citizen Eco-Drive photovoltaic wristwatches where the battery lasts for the life of the watch. It is premium priced and very successful.

Huge environmental and cost benefits

38% of energy is consumed in buildings and more affordable building controls of longer life are the focus of most of the 70+ companies in the EnOcean energy harvesting alliance, which provides interoperable wireless sensors and controls that never need a battery. For example, EnOcean has installed 4200 wireless and batteryless light switches, occupancy sensors and daylight sensors in a new building construction in Madrid. These are powered by energy harvesters and embedded in the building. This saved 40% of lighting energy costs by automatically controlling the lighting in the building, 30 kilometres in cables, 42 000 batteries (over 25 years) and most of the cost of retrofitting.

15-20 year’s life

Life exceeding that of alternatives by at least 10 years is now a strong selling point for most forms of energy harvesting. Perpetuum in the UK makes electrodynamic vibration harvesters where system life is expected to be in the region of 20 years because of the absence of batteries. KCF Technologies has vibration harvesters that are maintenance free for ‘at least 15 years’.

Suppliers of the EnOcean piezoelectric light switches and allied controllers using various forms of energy harvesting claim 25 years life, with over 500 000 installed already. We therefore have a pattern emerging by which the life of energy harvesting devices without batteries is at least 10 years longer than the life of battery driven wireless devices and this alone gives valuable paybacks. There is more: during the life of a battery, it may need recharging many times or otherwise have maintenance; energy harvesting is usually maintenance free.

Achieving the impossible

There is huge significance in progressing from billions of small batteries in use today to tens and hundreds of billions of small devices yearly that require power. The economically active population of the world is under six billion and they manage with about four billion mobile phones with batteries that are often flat and billions of electronic watches and similar items that need battery replacement all too often. However, whereas this is manageable because most people only have one or two of these products, the next stage involves people possessing hundreds of small powered devices.

Industry will need to manage wireless sensor networks involving tens of thousands of nodes with their own power. These cannot be visited without great expense and labour and some cannot be visited at all. We therefore hit a tipping point where it is not a matter of payback versus the labour intensive battery option, it is more a matter of doing it with maintenance free energy harvesting or not doing it at all.

Industrial and consumer applications lead the way

In the past, aerospace and military energy harvesting have attracted huge investment but we now have about 3000 satellites orbiting the earth and the largest expenditures and grandest projects are slipping into the past. By contrast, consumer applications of energy harvesting are rapidly increasing. They will remain dominant with industrial applications coming in to rival them.

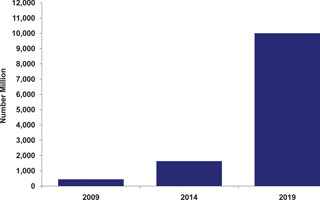

IDTechEx forecasts the number of energy harvesting devices sold globally to be as shown in the accompanying figure. The huge numbers in later years come from widespread use of electronic medical disposables, e-labels, e-packaging, e-posters. Whereas today most calculators have energy harvesting, in future most torches, lanterns, wristwatches, mobile phones and other electronic items sold in billions may employ it too.

Key enablers of the next generation

The next generation of energy harvesting devices will be smaller, lower in cost and have lives exceeding 20 years in many cases. Energy density will improve, but there is probably more scope for the efficiency to improve and that will also expand the addressable market. Many devices will be announced that work within the human body without need of further intrusive surgery. Many others will be embedded in apparel. Energy harvesting will power many of the billions of medical disposables needed for self-diagnostics and drug delivery as the demographic time bomb – too many old people – hits.

Among the key enablers of all this will be micro electromechanical systems (MEMS), both harvesting energy and sensing. Even more important will be printed electronics because this is key to improving performance, size and cost of photovoltaics, thermovoltaics and sometimes piezoelectrics and electrodynamics as well.

For example, thermoelectric elements less than a few microns in thickness are now offered that are far more efficient. Printed photovoltaics and piezoelectrics exist today and printed flexible electrodes are used with many forms of energy harvesting, including the experimental capacitive versions employing electroactive polymers. Printed electronics provides biocompatible, stretchable, woven and other versions needed in certain applications. Indeed, printed electronics are key to making the cost and form factor of the electronic circuits that convert energy harvesting more acceptable as well.

For more information visit www.idtechex.com

© Technews Publishing (Pty) Ltd | All Rights Reserved