The high cost of semiconductor manufacturing equipment is making continued chip-making advancements too expensive to use for volume production, relegating Moore’s Law to the laboratory and altering the fundamental economics of the industry, according to iSuppli.

“The usable limit for semiconductor process technology will be reached when chip process geometries shrink to be smaller than 20 nm, to 18 nm nodes,” said Len Jelinek, director and chief analyst, semiconductor manufacturing, for iSuppli. “At those nodes, the industry will start getting to the point where semiconductor manufacturing tools are too expensive to depreciate with volume production, ie, their costs will be so high, that the value of their lifetime productivity can never justify it.”

While further advances in shrinking process geometries can be achieved after the 20 nm to 18 nm nodes, Moore’s Law will no longer drive volume semiconductor production. iSuppli expects the semiconductor industry to reach this milestone in 2014.

More on Moore

Moore’s Law, named after Intel co-founder Gordon Moore, represents the foundation of the semiconductor industry, stating that the number of transistors that can be placed on an integrated circuit doubles every two years. For more than four decades, shrinkage of semiconductor processes to smaller and smaller sizes – known as geometries – has allowed Moore’s Law to remain on track.

This rapid advancement has enabled a continued rise in computing power that has yielded everything from PCs, to video-game consoles, to today’s advanced smartphone products. It has also brought down the cost of electronics to the point where capabilities previously available only in supercomputers now can be found in inexpensive consumer electronics devices.

Process procession

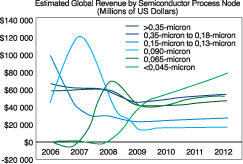

Historically, manufacturers of advanced semiconductor products like microprocessors or high-density memory migrated to more advanced smaller-geometry processes at a fast pace. They did this in order to reduce their manufacturing costs at the same rate or quicker than their competitors. This caused revenue generated by a specific semiconductor geometry to fall off rapidly after it had peaked. However, with the rising costs of new manufacturing equipment, semiconductor processes are expected to have more lengthy periods of revenue generation.

“The semiconductor industry will be living with historical generations of technology longer than it did before,” Jelinek said. “You are not seeing these geometries rise and fall off the way they did before. Rather, they are living on.”

Semiconductor revenue generated at the old 90 nm micron geometry tailed off dramatically after peaking. The newer 65 nm geometry is not declining so dramatically after reaching its zenith. The following geometry is likely to remain a major revenue generator for many years, Jelinek predicted.

The new dynamic

For the semiconductor industry, the slowdown in process technology transitions will mean that the industry will become more driven by economics than technology, with chip manufacturers attempting to squeeze as much as they can out of current geometries before moving on to the next level. “Historically, the focus in the semiconductor industry was always how quickly you could move to the next geometry node,” Jelinek said. “Now the question is how to make money by sustaining a specific node.”

Among the ways semiconductor manufacturers will try to keep existing processes going will be to employ 3D structures that allow more transistors to be packed into a single device.

© Technews Publishing (Pty) Ltd | All Rights Reserved