KM Product Design is a South African company that provides design and development expertise to individuals and companies with a promising idea or invention who require assistance in turning their concept into not only a reality, but a manufacturable product.

Based on the East Rand of Johannesburg, the company boasts a turnkey service from concept to final preparation for mass production. This incorporates modern software design, access to the latest rapid prototyping methods, and assistance in managing the tooling process through local and international partners. Its graphic design department can also design product brochures, technical manuals with illustrations, packaging and other graphic media.

KM holds the distinction of being the primary design consultant for six previous winners of SABS (South African Bureau of Standards) Design Institute awards, now known as the SABS Design Excellence Awards. Its experience extends from consumer plastic products to highly specialised industrial equipment, with a client base including the likes of Afrox, CSIR, Netstar, Sanji and Telkom, to name just a few.

Humble beginnings

The company was founded in 1993 by local industrial designer Peter Dreyer and Paul Kite, an English immigrant and design graduate of the Royal School of Art. Although its own beginnings were humble – run as it was from Kite’s house – Dreyer points out that KM Product Design’s inception coincided with an exciting time for the local product manufacturing industry as the world markets started opening after the first 1994 democratic elections.

“Technical drawing boards, air brush renderings and handmade prototypes were the tools of the trade back in those days,” Dreyer reminisces. “Industrial design was a foreign concept and many of our early customers came to us in desperation with a common brief: make our products as ‘sexy’ as the ones we have to now compete with!

“This is still somewhat true today as many of our new customers had world class technology but failed to package it in a well designed, modern enclosure that inspires appropriate value perception and market relevance. Kitemark Product Design, trading as KM Product Design, has grown exponentially over the last 21 years and today boasts both local and international customers that we assist with product development.”

Spreading its wings

While three moves to bigger premises during its history were necessary to keep up with its expansion, the company never strayed far from its roots as it has always been located within a one kilometre radius of its current facility in Edenvale.

Dreyer instils a business philosophy that places an emphasis on high regard for those that make it tick. “I have employed a number of industrial designers over the years and we currently have six qualified industrial designers on staff. Most of our staff has been with us for many years and we put an extremely high value on our staff members kindling a close, long-term working relationship with our customers.”

Together, KM’s current engineering staff complement – Tommy Fritz, Andre Kilian, Travis Maddox, David Stievenart, Andre Veenstra and Peter Dreyer – has more than 60 years of industrial design experience.

“Like most businesses, we thrive on repeat business and a large percentage of our customer base has been with us for many years,” explains Dreyer. “In fact, we still have a handful of customers that have been with us for more than 15 years. We become an integral part of their R&D teams and customers have learned the value of involving us during the inception stages, before the project is even defined.”

While the amount of business provided by word of mouth, as well as networking activities with developers, mould makers and manufacturers, has built a successful foundation, the company is now eager to take advantage of the increased capacity provided by the ability to more rapidly complete tasks successfully thanks to modern software and prototyping methods, in order to more actively promote itself and fuel its next stage of growth.

From crackpots to robots

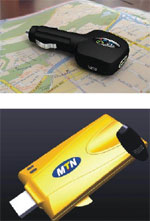

As an industrial design consultancy, KM receives a fair amount of enquiries from inventors that wish to commercialise their ideas. Dreyer says this has led to some very interesting enquiries and projects over the years, which has seen the company design everything from super high-tech electronic enclosures to simple plastic toilet seats.

“Needless to say we also get approached by a fair amount of crackpot inventors with their perpetual motion generators,” he muses. “Most of these ideas will only ever exist on paper and look like they belong in a Leonardo Da Vinci museum. Some optimistic souls simply refuse to accept any of the laws of thermodynamics or the fact that they are not the world’s luckiest inventor that just happened to have stumbled on the holy grail of free energy generation.

“One of the most fun projects we had was the mechanised entertainment robot called Robonii that we developed for the company Robonica a few years ago. The end result can be viewed on YouTube at www.youtube.com/watch?v=INsbxScFyiU. KM Product Design did all the styling and mechanical engineering design for the various gaming hardware items.”

Uniquely positioned

As to what makes KM Product Design unique, Dreyer recalls the time a customer put it best when he described the company as “a bunch of engineers with ponytails”. “That pretty much describes industrial design as the link between art and engineering,” Dreyer explains. “We first start a project at conceptual development, with a focus on aesthetics and basic configuration. We then drive the development home with good old-fashioned, sound engineering and optimisation for mass production.

“We do not manufacture in-house; we have established a vast network of suitable manufacturers and mould makers that we introduce our customers to,” he continues. “We basically sign off once the product is successfully produced. We have, however, made it a priority to expand our network and have also built up a close working relationship with manufacturers and toolmakers based in China.

Dreyer insists that the company makes every effort to support and retain South African business, but circumstances have necessitated that it look abroad for some essential manufacturing services.

“We have also broadened our service scope over the years by offering many other product development related tasks beyond the basic product design,” he expands. “Our graphic design department assists our customers with technical brochures, brand identity development, packaging design and even computer animations for marketing and website media.”

To infinity, and beyond

Bucking the pessimistic outlook that pervades the South African electronics development and manufacturing industry nowadays, Dreyer is full of excitement about the future as he sees the market opening up for South African manufacturers, especially in supplying technology products into the rest of Africa.

“We have had many successes with locally developed products that are specifically designed to meet African conditions and needs,” he explains. “Due to a weaker currency, many of our customers are also having huge successes in other international marketplaces. Sound technology, combined with a well designed product, offered at a fair price, will always result in a winner.

“The biggest advantage with a well designed enclosure is often not just superior aesthetics but also innovative ways of cutting manufacturing and assembly costs. This is becoming more and more important in South Africa as labour and material costs are escalating.”

Over the years Dreyer has seen a niche world market developing for well designed, specialised technology products from South Africa. “We seem to have a large number of small to medium sized companies that are developing world-class technologies for very specific niche markets,” he explains. “Some of these companies have a very interesting background and a lot of them were founded by ex-employees from the former military manufacturing industry, or even institutions like the CSIR, who have now moved into the private sector.

“Our local manufacturing support industry is still geared and willing to entertain low-volume manufacturing. Often bigger companies and big international factories are not prepared to manufacture small quantity production runs. Local plastic converters can often mould the plastic enclosure components cheaper in South Africa than even a place like China, especially now with our weaker currency.

Dreyer believes that South African companies often lose the manufacturing race when it comes to all the value-add factors that make up a competitive product. “This is where sound design can be a saving grace,” he says. “Design innovation and the correct technology application can drastically reduce mechanical assembly and production costs.

“We often forget that the value perception and outer aesthetic appeal of an enclosure becomes the face for the enclosed technology. A product that is perceived to be better value than a competitive product, but is lacking in design attributes, can often be marketed at a higher price.

In closing, Dreyer expresses his conviction that the local industry is in the most favourable position to develop technology products for the rest of Africa. “Apart from all the obvious demographic advantages that we have as a local industry, we have also all earned our insight into what works and what does not work in Africa. I believe we have opportunities in this country that the rest of the developed world no longer has. It is just sometimes a shame that foreign companies seem to be more effective at identifying our own birth right. We can determine our future by designing it!” he concludes.

For more information contact Peter Dreyer, KM Product Design, +27 (0)11 452 7999, [email protected], www.kmdesign.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved