Traditional membrane switches use pressure sensitive adhesives (PSA) in order to bond the individual circuit layers together. These adhesives however, yield a rough surface structure, which, in an assembled membrane switch, leads to small micro fissures that allow fluids and solvents to ingress over time.

All membrane switches that have been assembled using pressure sensitive adhesives will therefore, when exposed to fluids, chemicals or cleaning agents, lead to a small percentage of field failures. It is these field failures that in many applications lead to considerable cost for service calls and repair work, which are usually a lot more expensive than the actual membrane switch itself.

In order to prevent this, the Bergquist Company has developed HeatSeal. Schurter, which is a membrane switch manufacturer, will be offering HeatSeal solutions for those harsh environment applications where traditional membrane switches constructed with pressure sensitive adhesives (PSA) are limited or not suitable.

HeatSeal technology is a process, which welds the membrane switch layers together using high heat and pressure. The result is a totally sealed membrane switch that withstands permanent submersion in even the harshest solvents and chemicals, without the risk of field failures.

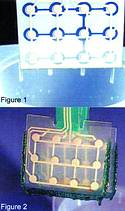

As an example, the figures illustrate how a HeatSeal membrane switch that has been exposed to a cleaning fluid (MEK methyl ethyl ketone) for two weeks shows no sign of leakage (Figure 1), whereas the pressure sensitive adhesives of conventionally assembled membrane switches are totally dissolved by the same substance within this amount of time (Figure 2).

Next to totally sealing the membrane switch and, therefore, protecting it against any form of fluid ingression, HeatSeal also extends the temperature range and eliminates the requirement for venting, by sealing in the air between circuit layers. This entrapped atmosphere expands at high temperatures creating a high pressure environment, which is used to open the membrane switch, therefore making HeatSeal solutions suitable for even automotive applications.

| Tel: | +27 11 786 0553 |

| Email: | [email protected] |

| www: | www.retron.co.za |

| Articles: | More information and articles about Retron |

© Technews Publishing (Pty) Ltd | All Rights Reserved