Mitsubishi Electric's NF series features IGBT modules that use CSTBTs. CSTBTs (carrier stored trench-gate bipolar transistor), which surpass the theoretical barriers for IGBT performance, have the most advanced fundamental characteristics while still using essentially the same technology as conventional trench IGBTs.

In planning NF Series products, ease of use and compatibility were considered, rather than focusing exclusively on reduction of losses. The NFH Series was developed at the same time for high-frequency switching applications.

The NF Series

Mitsubishi has marketed dual-IGBT 100 A to 600 A IGBT modules containing CSTBTs, developed as the fifth-generation IGBTs. This series serves the strong market demand for dual-element IGBT modules. The company's conventional H series product is used in a wide variety of applications, and many firms have developed a broad range of application technologies for these products. In order to take advantage of these existing technological resources while switching to state-of-the-art elements, the dual-element NF series features package dimensions (Figure 1), drive characteristics, short-circuit characteristics, etc, similar to those of the H series. The CSTBTs should be thought of as an extension on the tried-and-tested trench IGBT technologies, with improvements in terms of high reliability/stable supply design.

Based on the fourth-generation trench IGBT structure, this fifth-generation IGBT chip uses three superior technologies: the CSTBT structure (providing improved performance), the plugging cell merged (PCM) technology (which controls the channel density), and the light punch through (LPT) structure (which facilitates parallel connections with high-voltage elements and facilitates faster switching, while improving failure capability or endurance). Each of these technologies is described below.

The n- drift layer resistance, which is high when the element is OFF in order to maintain the breakdown voltage, is reduced by the injection of holes from the P collector region when the element is ON. The concentration of these holes falls with the distance from the injection point, so the resistance tends to remain high in the vicinity of the emitter. CSTBT is a technology in which innovations have increased the concentration of holes in the vicinity of the emitter.

On the other hand, even though trench IGBTs have the advantage of providing extremely high current densities, this characteristic becomes a disadvantage in applications that require shortcircuit capabilities. While short-circuit capabilities require the channel density to be reduced, simply expanding the gap between trenches has an impact on the withstand voltage. Given this, PCM technology fills in the trench gates for one out of every few trenches, causing the gate to short to the emitter to prevent operation. This makes it possible to obtain input capacitance characteristics and short-circuit capabilities similar to those of planar IGBTs.

The structures of IGBTs can be categorised as punch-through (PT) or non-punch-through (NPT) structures. Generally, PT structures, with their lower saturation voltage, are particularly effective for low withstand voltage applications, while NPT structures are more suitable for higher withstand voltages, where switching losses are a larger proportion of total losses and lower saturation voltages matter less. The light punch-through (LPT) structure is positioned between them, and is used in 1200 V-class IGBTs.

Because this product series is compatible with the H series, the rated currents (model names) are set in a way markedly different from general products. The CSTBT is a descendant of the trench IGBT, with an extremely low saturation voltage and high DC current-carrying capabilities; however, in many 1200 V applications where switching losses predominate, when the rated current is set by the DC current-carrying capability, problems arise in terms of compatibility with the H series. To ensure compatibility with units in the H series that have the same rated current for that type name, the margin in the NF series is about one rank above that which is usual for the current-carrying capability. While this causes a shift in the current-carrying capability ranking in the direction of having too large a margin for new designs, which often have lower switching frequencies, this approach was adopted to ensure compatibility with the H series.

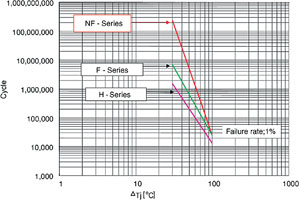

On the other hand, in the later part of the third generation products, Mitsubishi made major improvements in packaging (specifically in the U and F Series). The power-cycling life expectancy was improved dramatically through the move to a single-soldering cycle and through the selection of the optimal solder. The NF series from now on uses packages with improved internal structures while maintaining compatibility with the third-generation IGBT in terms of external dimensions, and power-cycling life expectancies have again been improved dramatically through the optimisation of the wire-bonding conditions and parameters (Figure 2). Similarly, major improvements in the later part of the third generation dramatically decreased the stray inductance of the main terminal parts, and, based on this technology, the NF series has succeeded in reducing the inductance by about half that of the H Series, while still maintaining compatibility with the H Series' dimensions.

The NFH Series

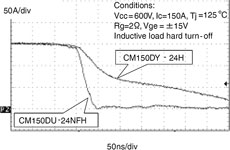

Mitsubishi has also marketed the NFH series of IGBT modules, taking advantage of broad latitude in adjusting the carrier density spread in the CSTBT structures to increase the turnoff speeds of the elements (Figure 3). The 30-60 kHz circuitry, and the H bridge circuit in particular, have been adjusted, targeting applications such as medical equipment, induction heating, welding equipment, high-frequency power links, etc, equipment that involves turn-on soft switching and turn-off hard switching. The turnoff speed for general-use IGBTs is rather slow, making them difficult to use in these applications. In particular, the low-noise counter-measures of recent IGBT modules often counter the requirements for high-frequency responsiveness. Generally, when minority carrier lifetimes are reduced excessively in order to provide high-speed response in IGBTs the on-state voltage drop will be extremely high due to the reduction in modulation in the n- layer at lower currents. However, this phenomenon is less likely in the LPT structure used in the CSTBTs for the 1200 V Class.

Based on the U and F series packages, with their reduced stray inductances, the NFH series takes the skin effect into account in strengthening the internal interconnections. The rated current, freewheeling diode, outline, etc, have been set independently in accordance with the fact that the NFH Series' IGBTs are used in applications that are very different from those of standard IGBT modules. The NFH Series of IGBT modules gives preference to switching speed over short-circuit capabilities. In this way, the NFH series specialises in high-speed turn-off characteristics, and even though losses are small, this series is not intended for general inverter applications, but rather can be used to pursue performance that has been difficult to achieve with conventional IGBT modules in high-frequency switching applications.

The new NF series, by incorporating the very latest technical developments while maintaining the greatest possible compatibility with the previous generation, ensure that the many companies using Mitsubishi Electric's products will be readily able to make the transition to take advantage of the superior performance offered with the minimum dislocation of their production lines. The NF and NFH series will also open up new applications where their superior performance will offer significant competitive advantages.

© Technews Publishing (Pty) Ltd | All Rights Reserved