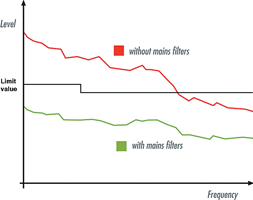

The range of MEF mains suppression filters from Murrelektronik reduce emitted interference and improve immunity from internal and external interference on mains and power-supply cables. EMC filters are thus important components in making machines or systems with frequency converters, pulsed power supply, or electronic devices, safe from an EMC point of view.

Technical advancements are making machines and systems increasingly smaller. At the same time, the quantities of data from sensor, actuator, measurement and control signals and modulation frequencies from fieldbus systems and networks is on the increase. Powerful electrical equipment is often located in the vicinity of electronics. Voltage supplies are often provided via pulsed power supplies. An increasing number of speed-controlled motors are being used in drive technology, most actuated by frequency inverters. Increasing pressure to reduce costs means that installations must be carried out as cost-effectively as possible. If planning mistakes are made and negligence occurs during installation, reliable operation in accordance with the applicable EMC regulations cannot be guaranteed. Also, work stoppages from problems such as sporadically occurring faults, influenced measurements and controllers, cost money.

Mains suppression filters, combined with EMC-oriented installation of switch cabinets and machines, help implement the protection specified in EU Directive 89/336/EEC, as well as machine guideline 98/37/EG. This increases both the safety and the availability of machines. The costs of loss of production and rectification of faults that stem from EMC problems are significantly higher than the purchase price of a filter. In the final analysis, it pays to take this into account when planning installations.

Product range

The range comprises clip-on single- and 3-phase mains filters up to 20 A for universal use. The integrated clip allows quick mounting and saves operating time since expensive drilling and screwing is not necessary. The shock-hazard-protected screw terminals are convenient to connect.

The new MEF 3-phase mains filters with a current range of up to 180 A have a remarkably compact book format for the high damping characteristics. Optimal space utilisation close to the feed or the source of interference, is achieved through end mountings. High operating voltages of up to 600 V a.c. allow them to be used worldwide.

The new 1 and 3-phase MEF EMC filters from Murrelektronik are bidirectional. These reduce interference (emission) and improve interference resistance (immunity) to internal and external interference on power and supply lines. Filters are therefore important components for protecting machines or systems, frequency inverters, thyristor switchers (SCRs), pulsed power supplies and electronic devices from EMC.

The range of products available from Murrelektronik includes snap-on 1 and 3-phase mains filters up to 20 A that can be used anywhere. Filters with 4-wire technology (3 phases + N) are particularly suitable as input filters and are used in cases where 230 V consumers are also present. The low consumption means that there is little pre-loading of FI protection switches, ie, the fault current protection switch is not triggered any sooner than necessary.

The integrated snap-on base allows the devices to be quickly attached to support rails, eg, next to input terminal blocks, saving time. The screw terminals are easy to connect and protected against touch. Unlike low-cost solutions with a plug connector, there is no risk of electrocution if the load side is unintentionally disconnected.

In residential areas or mixed residential/industrial areas, it is recommended to use 2-stage mains filters with increased damping in order to conform to the Class B interference emission limits defined in EN 55022 and 55011.

Variants

As well as universal filters, Murrelektronik supplies two variants of these 2-stage filters, which are outstanding because of their high energy absorption and wide-band damping behaviour up to 30 Hz.

The first product line is designed to suppress the essentially symmetrical interference (differential mode) that occurs between the lines in the low frequency range because of inductivity without interference suppression, and from conventional motor drives. The product line that is protected from asymmetrical interference (common mode) is mainly designed for the higher-frequency range with frequency inverters and switch mode PSUs. In practice, mixed interference usually occurs, meaning that both types of filter can be used. For optimum filter adaptation, such as with standard machinery, individual measurement on site or in the EMC test laboratory is recommended.

Cable-bound interference in mains AC voltage is suppressed by the low-pass filter-like functionality. This means that the filters can also be used for 24 V direct voltage supplies.

The 1 or 2 stage versions of the new MEF 3-phase filters are outstanding because of their excellent damping properties and low consumption, and their compact and lightweight design. The collective interference suppression, with just one filter per system, initially appears to be the cheaper solution, but becomes more complicated and expensive in an EMC-compliant installation with shielded cables. Individual interference suppression with separate filters at each interference source, connected by a cable that is as short as possible, provides maximum protection, also within the system.

Murrelektronik's wide standard product range covers a current range of up to 180 A. High supply voltages of up to 600 V a.c. allow them to be used worldwide. All filters comply with European standard EN 133200. EMC planning, EMC-compliant installation, interference suppression for inductive consumers and EMC filters help to make your system operate reliably and ultimately provide additional machine safety and availability.

For more information contact Retron, +27 (0)11 786 0552.

| Tel: | +27 11 786 0553 |

| Email: | [email protected] |

| www: | www.retron.co.za |

| Articles: | More information and articles about Retron |

© Technews Publishing (Pty) Ltd | All Rights Reserved