Conventional power factor correction (PFC) systems consist of a power factor controller and power capacitors. They are connected to the power line via electromechanical capacitor switching contactors. However, due to the discharge time of the capacitors, reset times are longer than 60 seconds.

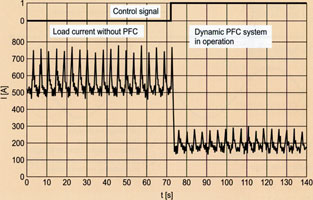

New applications are increasingly calling for technologies that respond in realtime. Here dynamic PFC systems such as electronic thyristor modules are replacing slow electromechanical switches. As well as shorter response times, longer service life is an important advantage. Thyristors are not prone to mechanical wear. Eliminating mechanical capacitor contactors also avoids high inrush currents. Thyristor modules switch the capacitors at zero-crossing, thus avoiding the inrush currents that can be as high as 200 times the rated current (Figure 1).

Dynamic systems open up new applications and offer a host of advantages:

* Reduction of reactive power and lower energy costs, even with rapidly changing loads.

* Switching times shorter than 20 ms.

* Reduced capital expenditure (distribution and transmission systems, cable cross-sections, etc) thanks to avoidance of peak currents.

* Stabilisation of line voltage.

* Prevention of flicker and smooth, transient-free switching.

* Longer service life of PFC system and equipment.

Dynamic power factor correction is used in welding equipment, industrial presses in the automotive industry, wind parks, cranes, lifts, and main motor starting compensation, where it makes the soft starter redundant (Figure 2).

One-stop shopping for dynamic PFC

Epcos offers a comprehensive range of products for dynamic power factor correction with two types of thyristor module. These include TSM-C modules that can handle reactive powers of 25 and 50 kVAr, the new dynamic power factor controller BR6000-T, PhaseCap PFC capacitors, and complete dynamic PFC systems.

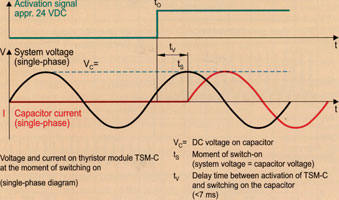

The self-monitoring TSM-C thyristor module is a dynamic electronic switch that can switch on PFC capacitors free of transients in a few milliseconds (Figure 3). It is distinguished by:

* Ease of assembly: the thyristor module can be used like a capacitor switching contactor; complete intelligence is integrated into it.

* Self-monitoring for capacitors handling up to 50 kVAr.

* No harmonics generated because complete sine wave is switched.

* Fast response times of less than 7 ms.

* Continuous self-monitoring of voltage, capacitor current and thyristor switch temperature.

* Cascading output.

* Alarm output on each module.

* Control and error message display.

The Epcos BR6000-T dynamic PFC controller (Figure 4) is the result of ongoing development of the BR6000 series, to which new functions have been added. It was specially developed to control the thyristor modules for dynamic switching and corresponding power factor correction. Thanks to the fast processor, short switching cycles are achieved. In addition to the switching time of less than 40 ms, the BR6000-T offers very fast setting of the power factor by simultaneous switching of several stages. Various parameters can be adjusted for perfect matching of the PFC controller to different thyristor modules.

The BR6000-T is available with six or 12 transistor outputs and one alarm terminal. A text-based, menu-driven display makes the PFC controller intuitive and easy to use.

Epcos offers one-stop shopping for dynamic power factor corrections:

* Processor-controlled PFC controllers with up to 12 outputs.

* Fast-switching thyristor modules.

* PCB-free PFC capacitors with integrated overload protection.

* Inductors for damping PFC capacitors.

| Tel: | +27 11 458 9000 |

| Email: | [email protected] |

| www: | www.electrocomp.co.za |

| Articles: | More information and articles about Electrocomp |

© Technews Publishing (Pty) Ltd | All Rights Reserved