A recent concept being implemented to power circuits is using energy scavenging. This makes use of energy collection through solar cells, piezoelectric generators, or other energy conversion devices. These devices collect energy from diffuse sources, convert it to electricity, and typically store it in a capacitor until it is required. In many situations, the sensor circuitry is not required to operate continuously and the energy storage is replenished during the sensor off periods.

In this article, Walter Bacharowski shows an example where a solar cell and a one-farad capacitor are used to power a remote motion-detector that uses an RF link to transmit the occurrence of any event to a central monitor. This type of sensor is advantageous because wiring is not required and battery replacement is eliminated.

Some circuitry is required to monitor the voltage on the capacitor and to signal other circuits that there is enough voltage to turn on and perform some processing. When the capacitor voltage drops below a predetermined voltage, the circuitry is disabled. In conjunction with the capacitance, the voltage on the capacitor is a measure of how much energy is available to power the external circuits. Typically, the energy scavenging transducers cannot supply enough energy to power the circuitry continuously. The capacitor is used to accumulate enough energy to power the circuitry for a period of time.

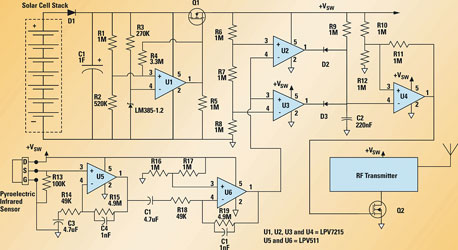

In this example (Figure 1), amorphic silicon photovoltaic cells are used, which are low-cost devices that can power circuits from ambient indoor lighting as well as outdoor lighting. Trade-offs can be made in the size of the cells, size of the storage capacitor, and how often the circuitry must operate. The voltage monitoring circuit is used to isolate the load circuitry from the energy scavenging components until enough energy is available for the circuitry to complete a task. The solar cell stack (D1 and C1) is the energy collection and storage component.

The monitoring circuitry must be very low power and operate over a wide supply voltage range. The circuit in Figure 1 uses the LPV7215 comparator, which has a typical operating current of 580 nA for the monitor function. The LPV7215 is used with the threshold and hysteresis setting resistors R1, R2, and R3, and the LM385-1.2 voltage reference to control a FET switch, Q1, to turn on power to the motion detection circuitry. The FET is on when the voltage on C1 is greater than 4 V and off when the voltage on C1 is less than 3 V.

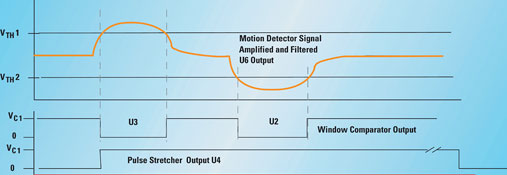

The motion detection circuitry uses a pyroelectric sensor followed by a high-gain band pass filter. The amplifiers U5 and U6 are LPV511 and have a typical operating current of only 880 nA while maintaining a 27 kHz gain bandwidth. The complete motion detection circuit only requires about 4 μA total. Figure 2 shows the output of amplifier U6 when a warm body moves across the field of vision of the pyroelectric sensor in addition to the window comparator and pulse stretcher signals.

The output of U6 is the input of a window comparator made from two LPV7215 comparators, U2 and U3, and resistors R6, R7, and R8. The threshold voltages are set at 1/3 and 2/3 of the switched voltage, +Vsw. The comparator's output switches low when the motion detector signal swings above or below the threshold values. The outputs of the comparators are OR'ed together into a pulse stretcher through diodes D2 and D3. The pulse stretcher, which is composed of U4, an LPV7215 comparator, and C2, R9, R10, R11, and R12, generates about a 0,5 second pulse that turns on the RF transmitter through Q2. The RF transmitter requires about 25 mA while the detection and monitoring circuitry requires only about 20 μA.

Calculating the capacitor size for energy storage requires an estimate of the current flow in the circuitry, what is the voltage change on the capacitor and how much time is required to complete a task. For example, when the transmitter is active, the circuitry of Figure 1 requires about 25 mA for operation. The solar cell selected can supply about 5,5 V at 10 mA and can charge C1 to about 4,9 V. (Solar cell voltage minus the diode, D1, equals voltage drop of about 0,6 V.) The time the circuitry can operate for a change in C1 capacitor's voltage from 4,9 V to 3,0 V is calculated from:

The transmitter is turned on for 0,5 seconds for each transmission so the motion detector can transmit about 156 times (76/0,5), without any recharging, before the capacitor is drained below the turn-off voltage of 3 V. During normal operation, the solar cell is constantly recharging C1 when light is available. The second area of concern for the energy storage is how long the motion detection circuit can operate without the capacitor being recharged. Using the equation above, calculate the operation time for the motion detection and voltage monitoring circuits using an estimated current of 20 μA and a change in capacitor voltage from 4,9 V to 3,0 V:

A final concern is when this circuitry is first installed. It will take some time to charge C1 to the circuit's operating voltage. This can be estimated by the following calculation:

An alternative to waiting for the solar cell to charge C1 is to connect C1 to a 5 V source and charge it just before installation.

This example demonstrates the use of very low-power amplifiers and comparators to implement remote wireless self-powered sensors. The motion detector circuitry shown here can be replaced with many other types of sensors such as temperature, humidity, and leak detectors.

For more information contact Simon Churches, Arrow Altech Distribution, +27 (0)11 923 9600, [email protected]

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

© Technews Publishing (Pty) Ltd | All Rights Reserved