Miniscule choke coils for 'small' products

1 November 2006

Circuit & System Protection

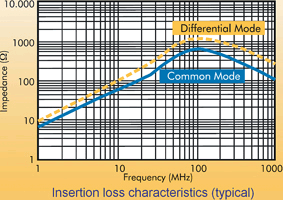

Small products will benefit from Murata’s 0504 size common mode choke coils. Developed especially for use in really small devices, the DLM11G series suppresses both common and differential mode noise.

Typical uses are in mobile phone audio lines like microphones, speakers and headphones and will include personal mobile equipment like PDAs, digital still cameras and MD players.

At 100 MHz, common mode impedance is of the order of 600 Ω and differential mode is about 1200 Ω. Rated current is 100 mA and rated voltage 5 V d.c. with a withstanding voltage of 25 V d.c. Minimum insulation resistance is 100 MΩ and DC resistance 0,8 Ω. The operating temperature range is -40 to 85 degree C.

The DLM11G is non-polarised. Both flow and reflow soldering are acceptable but Murata recommends reflow for optimal positional accuracy.

Further reading:

Smarter protection without disruption

NewElec Pretoria

Circuit & System Protection

Designed for operations still running without integrated automation, NewElec’s retrofit-friendly systems let you upgrade performance and safety without overhauling your entire network.

Read more...

Circuit breaker for reliable, compliant protection

RS South Africa

Circuit & System Protection

Legrand’s low-voltage power distribution portfolio encompasses the DX3 range of miniature circuit breakers, designed to deliver dependable protection in residential, commercial and industrial installations.

Read more...

Reducing noise on power supply lines

Future Electronics

Circuit & System Protection

Murata has introduced the EMIFIL ESD Series Noise Filters, a breakthrough solution engineered for superior noise suppression and enhanced electrostatic discharge (ESD) protection.

Read more...

Clearing the Static: Fundamental principles of static control

Actum

Circuit & System Protection

Controlling electrostatic discharge in electronics manufacturing is essential with effective ESD programs built on six key principles.

Read more...

Electrical fire safety in lithium-ion battery rooms

Circuit & System Protection

Pratliperl is a non-combustible, ultra-lightweight aggregate that can be mixed with cement and applied as a plaster or screed to walls, floors, and ceilings.

Read more...

Clearing the Static: ESD training in the workplace

Actum

Circuit & System Protection

To protect sensitive electronic components, A structured, consistent, and sustainable ESD training program is essential.

Read more...

Protect your pumps – protect your profit

NewElec Pretoria

Circuit & System Protection

In South Africa’s demanding agricultural landscape, irrigation is not just an essential service – it is the heartbeat of farm productivity.

Read more...

Clearing the Static: ESD and installation: A durable antistatic solution

Actum

Circuit & System Protection

ESD flooring provides a reliable, long-term solution for managing static electricity by safely dissipating static charges through the floor to a designated ground point.

Read more...

Why wait to automate

NewElec Pretoria

Circuit & System Protection

NewElec’s initiative helps you gain operational visibility via HMI or PLC by retrofitting intelligent motor protection relays without replacing MCCs or rewiring the plant.

Read more...

Clearing the Static: Effectively control static in your workplace

Actum

Circuit & System Protection

Controlling electrostatic discharge in the workplace is crucial to protect sensitive electronic equipment from damage. Implementing an ESD control program involves various measures and tests.

Read more...