The purpose of this article is to show the benefits of using lubricants in connector systems. Samtec choose a Nye Lubricant, product 502J-20-UV, and Samtec’s Q Strips QTH-060-01-L-D-A and QSH-060-01-L-D-A connector system. Nye’s 502J-20-UV lubricant is a synthetic lube used for connector contact interface applications as well as other uses. The main assumption is that a decrease in visual wear is a benefit of using lube in a connector system from both an electrical and mechanical standpoint.

The test systems were divided into four groups:

* Group 1: 100 cycles without any application of lube (control samples).

* Group 2: 100 cycles after one application of lube at zero cycles.

* Group 3: 100 cycles with application of lube at 0 and 50 cycles.

* Group 4: 100 cycles with application of lube at 0, 25, 50, and 75 cycles where a cycle is defined as one insertion and one withdrawal.

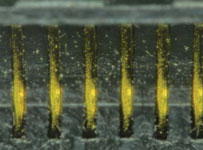

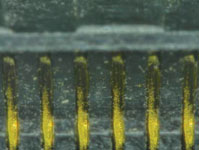

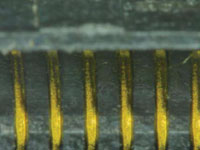

Photographs of the QTH Series (terminal) and QSH Series (socket) are included from this testing as both halves of the connector system need to be monitored for possible wear tracks. The lubricant was applied to the QTH Series in all test groups mentioned above using two wipes of the brush of lube and re-dipping the brush in the lube after each wipe. Figures 1 and 2 show the QTH Series and the QSH Series without any cycling or wear.

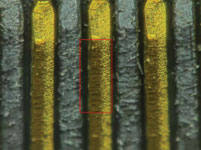

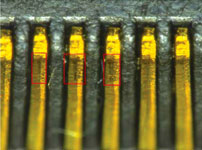

Figures 3 and 4 show Group 1 connectors after 100 cycles with no lubrication added. Note the ‘channel’ that has dug into the QTH Series terminal pins highlighted inside the red boxes in Figure 3.

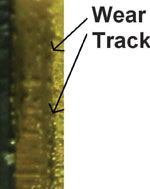

Figures 1a and 3a show a side-by-side comparison of the Figures 1 and 3 detailed inside the red box. The wear track in Figure 3a is clearly evident.

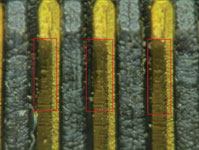

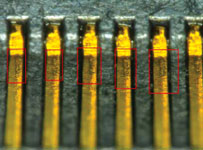

Figures 5 and 6 are photos from Group 2 after testing at 100 cycles with one application of the lubricant applied at 0 cycles. Note the wear tracks on the QTH Series terminal pin in Figure 5 inside the red boxes.

Figures 7 and 8 are photos from Group 3 testing. These connectors have lubrication applied at 0 cycles and again at 50 cycles. Again, these photographs were taken after 100 cycles. The wear track is blotchy and less evident, but still exists.

Figures 9 and 10 are from Group 4 testing, and they represent the connectors with lube applied at 0, 25, 50, and 75 cycles. Defining a wear track is visually difficult.

In summary, it can be concluded that applying a lubricant regularly to a connector system, in this case a Nye lubricant, can have a major impact on contact wear. The frequency at which the lubricant is applied will impact the amount of cycles a contact system can be rated at. The photographs showing the application of lube at 0 and 50 cycles show a vast improvement in the plating. The Group 4 test connectors show virtually no wear at all, almost as if they had not been cycled 100 times.

An interesting note from this experiment is that the QSH Series (socket) parts show no change throughout the entire process. The other variables that cannot be controlled (contact shape, wipe surface area and plating thickness) may also contribute to this lack of change.

As for practicing in the field, Samtec recommends applying a lubricant to Q Strip QTH-060-01-L-D-A connectors every 25 cycles for optimum life span and minimal cost. Applying a proper lubricant to both the QTH Series and QSH Series connectors will also have an impact on the contact wear, which in turn equates to more cycles the connector assembly can achieve.

For more information contact Samtec, +27 (0)11 452 8112, [email protected], www.samtec.com

© Technews Publishing (Pty) Ltd | All Rights Reserved