The hot aisle/cold aisle concept has been around for years now and has been adopted by most data centres. The concept is simple, involving the lining up of server racks in alternating rows with one row used as the cold air intake and another used for hot air expulsion.

Most data centres utilise HVAC systems to pump pressurised air in, to maintain a server inlet temperature within the proper temperature range of 18–27°C and an absolute humidity range of 5,5–15% RH. With the advent of highly populated server racks and the equipment producing higher and higher power outputs, racks can now reach up to 10 kW or more in heat expenditure at times. This design struggles because it lacks precision. The HVAC system addresses the entire data centre room, meaning that some areas get excessive cooling whilst other areas do not get enough.

Experts argue about the effectiveness of the hot aisle/cold aisle system, with some claiming that if the hot air is not captured and sent back to the computer room airconditioning plant (CRAC) then air flow in the centre short circuits some of that hot air back into the cold aisles, thereby reducing effectiveness by up to 40%. Coupled with this, organisations are demanding more environmentally friendly working practices. As much as 50% of a data centre’s energy bill is from infrastructure (power and cooling equipment).

Professionals facing such problems should first evaluate their cooling architecture and determine if the capacity exists and to then compute future loads. If this capacity does exist, then the goal should be to harness it. To focus the cool air precisely where it is required, one of the more practical air management strategies is cold aisle containment.

What is cold aisle containment?

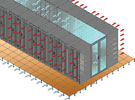

Cold aisle containment augments its predecessor’s (hot aisle/cold aisle) arrangement, but simply put it is a system that ‘contains’ the cold aisle, which effectively becomes a room unto itself, sealed with barriers made of metal, plastic or glass.

By using a cold aisle containment system, chilled air which is delivered from under a raised floor, is directed up and into the cold aisle and then through the perforated doors directly to the higher density servers. The roof and the walls of the containment ensure that the only place the air can exit is through the rack mounted equipment. The exhaust air, because of the boundaries, routes back to the hot air handlers only, eliminating previous concerns of hot air contamination and hot air recirculation.

Initial barriers were of a simple design, using vinyl curtains commonly used in industrial clean rooms and freezers. Leading cabinet manufacturers are now bringing their own cold aisle containment systems to the market. The barriers, instead of vinyl, are precision manufactured from steel and safety glass, with inserts to provide a viewing window into the cold aisle.

Manufacturers can even provide for in-row airconditioners which are embedded within the row of server racks, immediately capturing server exhaust air, conditioning it and distributing it back to the cold aisle.

Advantages

The advantages of cold aisle containment are:

* Increased cooling capacity to maximise the use of existing data centres.

* Life extension of existing data centres, by better utilising available space.

* A cost effective solution.

* Better heat transfer, thereby offering a higher delta-T, resulting in more cooling with thermal management.

* Lower air flows required, extending the life and efficiency of the CRAC. When airconditioning units are operated at full load, their efficiency decreases. At a speed of 50% or less, CRAC units can be operated more energy efficiently.

* Eliminates hot spots within the aisles.

* No additional lighting required, as the glass top and split doors utilise the room’s lighting.

* Additional security measures can be built in for each aisle, with restricted access rights.

* Contained fire systems per aisle.

© Technews Publishing (Pty) Ltd | All Rights Reserved