Consumer electronic products are getting smaller. Electronic systems in new cars and trucks are more prevalent. The aerospace and defence industries are also tightening environmental specifications as designs become smaller and more versatile. These trends require that the instrumentation used in all phases of development – design, debug and validation – work well in increasingly severe environments. These environments especially pose challenges for oscilloscopes and probes.

The probe challenges are due to drastic temperature swings, difficult to access or tiny DUTs (devices under test), as well as some mechanical considerations. The good news is that with some care, a simple understanding of what to expect in these extreme environments, and with a measure of common sense, it is possible to make high quality reliable measurements using readily available probes and accessories.

Extreme probing can be thought of as any probing situation in which, without proper consideration, it is possible to cause damage to probes and accessories, or make an unreliable or poor measurement. Common hacks that engineers use to make these measurements often have dire consequences when it comes to signal integrity. Other extreme situations can lead to probe failure, no matter what steps are taken. In these cases there are several strategies that can help extend probe life as long as possible.

Extreme geometries

With ever-shrinking component sizes, engineers often find themselves probing leads that are difficult to see with the naked eye, and even harder to maintain good electrical contact with, particularly using handheld browsing probes.

Most probe manufacturers offer interchangeable probe heads. These systems are the best approach for electrical performance-critical applications, and they also offer convenience.

With these types of probes, engineers purchase a probe amplifier and any number of heads, each tailored to a particular probing situation. With a solder-in probe head, the small inconvenience of carefully soldering the probe in place can save huge amounts of time when returning to the test point later; the connection only needs to be made once, which is very useful for hard-to-access connections.

For designs with a considerable amount of test points, however, this can get costly, since probe heads are typically precision electrical components. Variations of the conventional solder-in probe head, offered by probe manufacturers, solve this problem.

ZIF (zero-insertion-force) probe heads and tips, for example, usually work with differential probe amplifiers. These can reduce probe costs significantly when many high-performance measurement points are needed. These probes typically have disposable tips that can be soldered down to various places on a circuit board. The more expensive and sensitive probe head can then be shuttled between these tips.

One may be tempted to add length to the tip wires of probes to access hard-to-reach areas. Active probes typically have a bulky amplifier near the end that may not fit into tight spaces, or the oscilloscope may be far enough away from the device that the probe cables will not reach. Some manufacturers offer probe heads or tips that extend this dimension. These tip wires can be modelled as coupled transmission lines. Typically, the termination of these wires in the probes has higher impedance than the characteristic impedance of the wires, which causes the input impedance to resonate low at the 1/4-wave frequency. Increasing the length of the wire increases the length of the transmission line and therefore pushes the resonant frequency lower, decreasing the usable bandwidth of the probe. It is important to realise that spreading the tip wires apart results in the same effect, namely decreasing measurement bandwidth.

Tip-resistor tips

A tip resistor, which can usually be found on all high-bandwidth probes, helps alleviate the resonance issue by limiting how low the input impedance can resonate. It is important that this resistor be as close to the DUT as possible. Unfortunately, the tip resistor does not prevent the decreased bandwidth caused by longer tip wires. Although doing so may seem like a quick and easy way to probe tricky devices, extending the length of tip wires is not a practical route to quality, high-bandwidth measurements.

Understanding details of a probing system can help the user make reasonable decisions when pushing designs and equipment to extremes, and certain probing architectures are more suitable for use in extreme measurements. Traditional probe architectures use a relatively high-impedance compensated divider in front of a high-impedance voltage-input amplifier. Due to the high impedances, this topology does not lend itself to the use of controlled impedance transmission lines. As a result, compensated dividers must stay within close proximity of the amplifier.

Most probe manufacturers now use the concept of a lump-in-the-cable, where a minimal passive tip is connected via flexible small-diameter coax cabling to an amplifier with an input impedance that is equal to the characteristic impedance of the coax. This forms a terminated transmission line system, with fewer parasitic effects and lower loss of fidelity than that of traditional systems.

The topology also enables different probe head tips to be used for different applications. In the case of extreme probing, the transmission line architecture offers a huge advantage. The length of the transmission line can be increased dramatically without a loss in bandwidth. As such, coaxial extension cables can provide an electrically sound approach to the need for additional probe length.

Adding several feet between the probe amplifier and the probe head can be used with lump-in-the-cable probe architectures. It should be kept in mind that a longer transmission line between a probe head and the probe amplifier does have minor impacts on signal integrity. Longer coax cables will exhibit some loss, and may increase equivalent input noise. As such, it is very important to use high-quality coaxial cables for these connections.

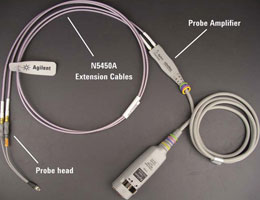

The two most important qualities in cables are phase matching and loss. Deviations from a perfect phase match will degrade the signal integrity of the differential signal arriving at the amplifier. Minimising cable loss will also help minimise in-band loss that manifests itself in the time-domain by reducing rise times. Agilent’s N5450A extension cables, for example, are low-loss cables that come in phase-matched pairs, resulting in minimal impacts on signal integrity.

Caring for extension cables

Such extension cables permit measurements in complicated setups and, in some cases, a measurement may even be impossible without their use. They are especially convenient when probe amplifiers do not fit near the DUT. The cables permit the amplifier to remain outside an enclosure, away from the DUT. In combination with solder-in probe heads, probe amplifiers can be interchanged among cables without turning off the DUT.

When snaking extension cables through an enclosure or fixture, it is best to relieve strain with Velcro strips or double-sided tape, or low-temperature-melt glue. Strain relief should be used at critical points where an accidental tug could cause a broken electrical contact. Any glues or tapes near probe heads should be carefully applied; as a rule of thumb, these must be kept at least 6,5 mm away from the connection wires in order to avoid mechanical damage or electrical performance degradation. Even a small amount of extra adhesive very near probe tip wires can significantly change electrical response.

Dealing with temperature

Testing circuits over extreme temperature ranges is now quite common. Agilent classifies temperatures into three general ranges. First is a so-called standard range, over which products are fully warranted. It spans +5°C to +40°C. A more severe range, typically used when abuse-testing consumer electronics, is -25°C to +80°C. Finally, an extremely harsh range, typically used in the automotive and aerospace industries, is -55°C to +150°C.

Active probes, which typically have an amplifier ASIC built into the probe cable (that is the aforementioned lump in the cable), cannot withstand temperatures outside of the standard range, due to precision electrical components that make up the amplifier, as well as thermal dissipation issues at high temperatures. It would be very impractical and expensive to develop an active probe amplifier that can withstand, and operate reliably in, these extreme temperature ranges. Also, scope probe calibration assumes that the ambient temperature surrounding the probe amplifier and oscilloscope does not change significantly over the course of a measurement.

A much more practical approach is to leave the amplifier at ambient temperature, while exposing just the probe head to the extreme temperatures. Probe heads are made up of only passive elements and are not necessarily as sensitive to extreme temperature swings. Agilent has tested a variety of its InfiniiMax probe heads over these three temperature ranges². Users should check with their probe manufacturer to learn the absolute temperature limits of its equipment.

With extension cables, it is possible to subject the DUT and probe heads to drastic temperature swings, such as in a temperature chamber, without affecting the probe amplifier or oscilloscope.

Exercise control

While it is possible to simply use heat guns and freeze spray to heat and cool circuits, these methods provide very little control, or consistency, over the heat that is applied or removed. Using a heat gun, it is very easy to far exceed the material limitations (such as melting points) of probes and circuits. A temperature chamber provides a controlled environment, resulting in much better temperature accuracy.

At extreme temperatures, particularly in the most aggressive temperature range, many material properties of components can drastically change. Plastics can become brittle and fragile when cold, and most approach their glass transition temperature, or melting points, around +150°C. Special attention should be paid to cable jacketing, as it is especially vulnerable to high temperatures. In addition, kinking probe head cables and DUT cables should be avoided if they will experience very high temperatures.

All materials change shape with changes in temperature (some more so than others). This means electrical opens and shorts can occur and disappear as temperatures change. In addition, electrical properties of passive components can change as their material structures shift with temperature.

The most important temperature issue, however, is the temperature behaviour of active components, such as ASICs, FPGAs and other components with behaviour profiles that depend heavily on temperature. These components are important to probe and investigate over wide temperature ranges to find glitches and other errors that might not show up under normal operating conditions. Using approved probe heads and appropriate extension cables, it is possible to make electrical measurements of these components over a very large range of temperatures.

Fixturing and securing probes is important when they are connected to a device in an environmental chamber, since it is nearly impossible to make careful positioning adjustments once the device and chamber are at an extreme temperature. Most glues and tapes do not handle extreme temperatures well. It is good practice to test an adhesive’s unknown temperature properties in a safe area (Agilent probe head cable jacketing can be considered a safe area, even if the adhesive disintegrates or flows, the cable jacketing will protect the centre conductors and signal integrity of the probe head).

Moisture mania

Another consideration for drastic temperature changes is the formation of condensation on the probe components (as well as the DUT). Water can cause shorts and result in electrical damage to the probe heads or DUT. If condensation begins to form, the user must disable power to all devices and wait for the water to vaporise before proceeding with additional testing.

It is important to note that lifetimes of all components, circuits and probes are significantly shortened when used in the most extreme temperatures. Repeated temperature cycling, in particular, is very harsh, which is why lifetime testing of designs is typically performed with extreme temperatures in HALT (highly-accelerated lifetime testing) chambers. This means that even though probe heads can be used in these extreme ranges, they will have a shortened lifetime. Customers should check with their probe manufacturer for reasonable cycle limits to expect for qualified probe heads².

Probe head failures are also more likely at extreme temperatures. Depending on the measurement, a probe head failure due to extreme temperature cycling may not be immediately obvious from the measurement on the oscilloscope. For instance, the symptom of an Agilent probe head failure due to temperature is a DC open circuit on either the positive or negative side (this varies with probe manufacturer). If a failure is suspected, it is important to measure the continuity from the probe tip to the SMP connector on each side. The DC resistance should be about 25 kΩ.

Keeping track

It is a good idea to keep probe heads that are deployed in extreme temperature situations isolated (and labelled differently) from normal probe heads. Input resistance of the probe heads can be measured before extreme tests to make sure they will still make a reliable measurement. Cable jackets may also stiffen and discolour during extreme temperature testing. This is normal and should not be a cause for concern. Note that +150°C is near the reflow temperature of most PVC-type plastics, such as those used on Agilent probe head jackets. As long as the coax cable is completely covered by the jacketing, it is functional.

Most high-performance RF cables are made using a Teflon dielectric. Depending on the manufacturer, this can be either extruded or made of tape. Tape dielectric cables are typically more flexible, but they can be more fragile as well. Kinks and excessive bends can cause permanent deformation of the dielectric in cables, which can affect electrical performance. Care should be taken to not drape probe head cables or extension cables over sharp objects, such as heatsinks, that could slice through heat-softened jacketing. A cable draped over an electrically active area could also potentially melt the jacket and short that area to the cable shield.

Shock and vibes

Another aspect of lifetime testing and real world product testing involves mechanical vibration and shock testing of designs. These can simulate the dropping of a cellphone, for example, or the installation of electronics in automobiles. Probing considerations for these cases is similar to that of extreme temperatures and extreme geometries; protect the sensitive probe amplifier, use solder-in probe heads or tips to avoid open circuits when connecting to DUTs, and strain-relieve probe heads and cables to prevent movement from causing any disconnects.

For the most part, common sense and a simple awareness of the limitations of probing equipment can guarantee long equipment lifetimes and quality measurements. Understanding their probing system architecture and behaviour can help the user make reasonable choices when pushing the physical limitations of equipment. Moreover, most oscilloscope manufacturers make a variety of accessories that can help with special applications.

References

1. Dascher, Dave, The Truth about the Fidelity of High-Bandwidth Voltage Probes, Agilent Technologies Application Note 1404, http://cp.literature.agilent.com/litweb/pdf/5988-6515EN.pdf

2. Agilent Technologies, 1168A and 1169A InfiniiMax Differential and Single-ended Probes, Agilent Technologies User’s Guide, http://cp.literature.agilent.com/litweb/pdf/01169-97007.pdf

| Tel: | +27 12 678 9200 |

| Email: | [email protected] |

| www: | www.concilium.co.za/test-measurement |

| Articles: | More information and articles about Concilium Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved