The design of AC/DC power supplies is inevitably evolutionary, rather than revolutionary. It develops largely as a result of gradual improvements in semiconductors and passive component technologies and materials. Invariably, power supply design objectives involve not only meeting basic input and output specifications but also meeting them within a given package size and within tight cost constraints.

XP Power has designed several families of AC/DC power supplies in the last couple of years, with output ratings from 40 W to 350 W. This article offers insight into some of the techniques that have worked for the company in producing units that both perform to their specifications and meet international standards with respect to EMC performance, safety and input protection. In all of these units, achieving performance objectives within the industry’s smallest packages has always been the aim, so many of these tips involve saving space without compromising electrical performance. As far as possible, the ideas are presented in a logical sequence from the input to the output of the power supply.

1. Input filters

The largest components in input filters are the inductors and capacitors. It pays to keep track of the latest products from all of the main toroid manufacturers as sizes continue to shrink with developments in materials. With respect to Class X (across the line) capacitors, one may be tempted to use ceramic types for their small size. However, these can fail catastrophically in the face of input spikes.

Metallised polypropylene types, while larger, cope much better with these spikes as they have an inherent self-healing property. Self-healing removes a fault or short circuit by vaporising the electrode in the region of the short and restoring the capacitor to useful life. Any loss of capacitance is negligible in normal operation. As with magnetic components, there are gradual reductions in component size over time.

2. Inductors and transformers

To meet safety requirements with respect to creepage and clearance, a physical safety margin usually has to be left at the edges of bobbins used for winding inductors and transformers. XP Power has found that a triple-insulated, UL-certified copper wire can remove the need for these gaps; one can then wind right to the edge of the bobbin. This can reduce the overall size of the switching transformer, often the largest component on the board, by as much as 20%.

3. Input capacitors

The working voltage of aluminium electrolytic capacitors should be selected carefully to get the best combination of minimum size and good operating life. These capacitors have longer operational life when operated at no more than 80% of their rated voltage. If the capacitors are used at full rated voltage, leakage current produces heating losses that can degrade the components. The rule of thumb is that every 10°C increase in temperature halves the life of the capacitor.

In practice, the dielectric layer in the capacitors will reform to the voltage at which they are being used, and any voltage surge can result in circuit failure, so the design should take this into account too. Components with 105°C temperature specification should be used for longest operating life.

In practice, a relatively large capacitor will be needed anyway, not just for ripple reduction but to provide the required DC hold-up time in the event of short-term disruption in the AC input. Typically, a hold up time of 10–20 ms is needed. Large electrolytic capacitors have high equivalent series resistance (ESR) at higher frequencies, so it is always good practice to include a much smaller capacitor – often a plastic film type, around 0,22 microfarads – in parallel to reduce this.

4. Input switch

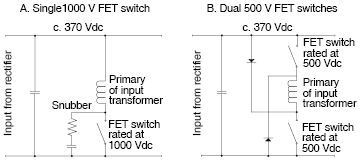

Most designs are based on a DC input to the switch of around 370 V (based on two times the highline AC voltage of 264 V). If a single MOSFET is used for switching, the back EMF generated by the stored energy in the input transformer primary when the switch opens will mean that a 1000 V d.c. rated MOSFET must be used. These are available but they are relatively expensive and have high forward resistance (RDSon) – perhaps as much as 40 mΩ – so efficiency is compromised. The designer will also need to include a snubber circuit to prevent high voltage spikes damaging the input capacitor and add a reset winding in the main transformer or other components, so component count, cost and board space are all increased. A smarter solution is to use two 500 V MOSFET switches (S1 and S2) configured as in Figure 1.

The switches operate simultaneously on either side of the transformer secondary and the diodes conduct at approximately 1 V above the input voltage, clamping the maximum voltage created by back EMF, protecting the input capacitor and eliminating the need for a snubber circuit. 500 V MOSFET switches are around one-sixth of the price of 1000 V-rated versions and devices with RDSon as low as 5 m are now available from a number of vendors.

5. Silicon carbide (SiC) rectifiers in boost converters

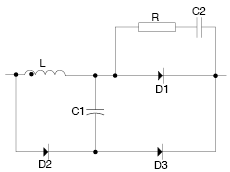

These may appear to be expensive but when one calculates the reduction in component count that is possible, the reduced power supply assembly cost and the savings in board space, this cost disadvantage is often wiped out. What is more, their use can deliver a 1% improvement in total power supply efficiency. Conventional diodes permit high reverse current and the energy needs to be dissipated in a snubber circuit consisting of two diodes, two capacitors, a resistor and an inductor, as shown in Figure 2. The negligible reverse current of the SiC diode eliminates these six components and reduces losses, leading to improved efficiency.

6. Control circuits

It is now economical to combine through-hole and surface mount techniques in the design of AC/DC switchers. Control functions can be implemented on the underside of the printed circuit board utilising surface mounted devices.

7. Cooling

Where possible, power semiconductors can be affixed directly to the power supply case or U-channel; one no longer requires thermal pastes. Thermal transfer components allow the tabs of power devices to be soldered directly to a copper pad that is already bonded to an electrically insulating but thermally conductive substrate. This approach is inherently more consistent and reliable than using thermal pastes. Where forced-air cooling is needed, one might consider the use of 3-wire intelligent fans. The fan speed varies with temperature to ensure that the fan only runs as fast as it needs to for given operating conditions. This reduces both noise and power consumption.

However, the relatively high prices of these fans, and the ready availability of low-cost fan control chips, makes implementing one’s own control circuit more cost-effective. Fan noise is another consideration. The format and spacing of finger guards should be experimented with. XP Power finds that placing finger guards a few millimetres away from the panel on which the fan is mounted, rather than flush with it, can reduce fan noise by some 5 dB to 6 dB. In a system that uses a number of power supplies, this is a very audible reduction.

8. Digital control

One must not get carried away by all the hype about digital control for AC/DC power supplies, unless the application absolutely needs it. Digital control has been widely implemented in point-of-load converters but it adds considerable cost to AC/DC power supplies. The chips may now be available cheaply, but when one considers the additional components needed, manufacturing costs and the cost of connectors, implementing digital control will add to the cost of an AC/DC power supply. This may be acceptable for a 1 kW power supply, where it is a small proportion of the total cost, but for low- to medium-power units, the additional cost can rarely be justified.

9. Mechanical design

There is always room for creativity in mechanical design. The range of applications for which the power supply may be used should be considered at the outset. For example, it may be possible to design the overall physical dimensions so that the power supply will fit horizontally or vertically into an industry-standard enclosure format. The printed circuit board can be designed to accept plug-in connectors or screw terminals; this adds no cost but greatly improves the application flexibility. The small things, like accessibility of fuses and making cable retention devices reversible, should be kept in mind so that the walls of the system enclosure or other protuberances do not obstruct them.

Stacking components to save PCB space is another technique that is often overlooked. For example, it may be possible to stack the inductors in a filter network on top of capacitors, simply fixing them with adhesive. This can also help EMC performance by keeping filter component interconnects very short.

10. Component layout

To look at some power supplies, one might think that the components were dropped onto the board from a great height and then connected together. Careful component layout, that follows a logical flow from input to output, is good engineering practice. The product looks better, is easier to test and service and it performs better. It should be borne in mind that every bend in a PCB track adds a little inductance that can create EMI.

For more information contact Edwin Brown, Vepac Electronics, +27 (0)11 453 1910, [email protected], www.vepac.co.za

| Tel: | +27 11 454 8053 |

| Email: | [email protected] |

| www: | www.vepac.co.za |

| Articles: | More information and articles about Vepac Electronics |

© Technews Publishing (Pty) Ltd | All Rights Reserved