Solar is a natural energy source for many battery-powered applications. With energy harvested from the sun, the size of batteries can be reduced, or the battery life of a system can be extended. All that is needed is a solar module, right? Is it really that simple? Let us take a look at what is possible in photovoltaic (PV) solar powered applications.

In its simplest form, a solar cell is essentially a specialised p-n junction, a type of diode. When direct sunlight or indirect light is applied to the cell, photons strike the cell and collide with electrons. When electrons are impacted with enough energy, they can be elevated from the valence band to the conduction band, and when swept across the semiconductor junction, an electric current is produced.

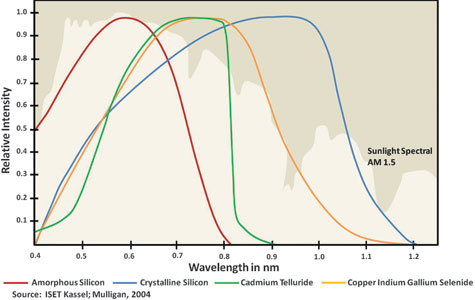

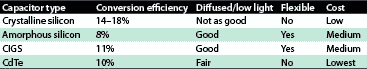

Multiple PV technologies are used to create solar cells – crystalline silicon cells have been used for decades. Thin film solar materials are amorphous silicon, cadmium telluride (CdTe) and copper indium gallium diselenide (CIGS).

Each technology has different efficiency, performance characteristics and cost. One unique feature of solar modules is that they are sensitive to temperature. Generally, the higher the temperature, the lower the power output. In addition, solar cells degrade over time, on the order of 20% over the course of 20 years.

How to maximise energy from solar modules

For off-grid applications, the most commonly used cells are crystalline and amorphous silicon. One of the features of crystalline silicon is that its spectral response curve shows that it is most responsive to the infrared spectrum of light. Direct sunlight is needed for crystalline silicon solar modules to be most effective.

Amorphous silicon cells are less efficient than crystalline silicon (a larger area is needed to produce the same amount of energy). However, amorphous silicon has a spectral response very similar to that of the human eye. It produces the most energy from light in the visible spectrum.

This means that amorphous silicon solar cells will produce energy from indirect sunlight, and even from indoor light, under conditions that will not produce much usable energy from crystalline solar cells.

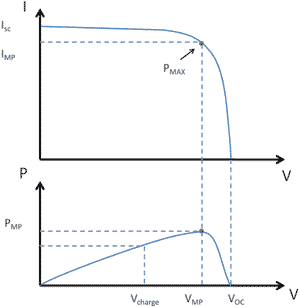

Solar panels have a characteristic I-V curve which varies depending upon irradiance and temperature. Short circuit current (ISC) and open circuit voltage (VOC) are key operating points as shown in Figure 2.

As can be seen, there is a point on the IV curve where the panel will be generating maximum power; this is called maximum power point voltage (VMP) or maximum power point current (IMP). In many solar applications, the system is designed to operate the panel at this point, generating maximum power. This is called maximum power point tracking (MPPT).

Because of the maximum power point feature of solar modules, if the impedance of the load differs significantly from the impedance of the module, much of the energy generated can be lost.

Consider a system to charge a 12 V lead acid battery with a typical 5 W solar module. In this case, VOC is usually around 21 V, and VMP is around 17 V. If the 12 V lead acid battery is attached directly to the solar module, the output voltage of the module will drop to 12 V.

In Figure 2, if VOC is 21 V and VMP is 17 V, one can see that dropping the output of the solar module to 12 V will drop the power of the module by roughly 30% (shown as Vcharge).

What happens to the rest of the power? It is dissipated as heat in the module, and is not used at all. How can most of the power available from the solar modules be used? By making sure that the module operates at the VMP using MPPT.

MPPT can be performed in a variety of ways, usually through an active electronic circuit. One method is called fixed voltage. The circuit removes the solar panel from the load, and measures VOC and ISC. The VMP is then calculated based on the datasheet of the solar module being used. This fixed voltage should be adjusted based on temperature.

Another common method is to use a specialised DC-DC converter. This method frequently combines both MPPT and battery charging, using feedback loops both at the input to the converter from the solar module and at the output of the battery.

One of the most common MPPT algorithms is called ‘Perturb and Observe’. The controller measures the output power of the solar module, and if it is higher than the previous reading, it bumps the output voltage in the same direction as the previous adjustment. If the output power has decreased, it bumps the output voltage in the opposite direction. This is commonly called a hill-climbing algorithm.

Many other MPPT algorithms exist, but the goal of all of them is the same: to operate the panel as close as possible to the maximum power point of the power curve.

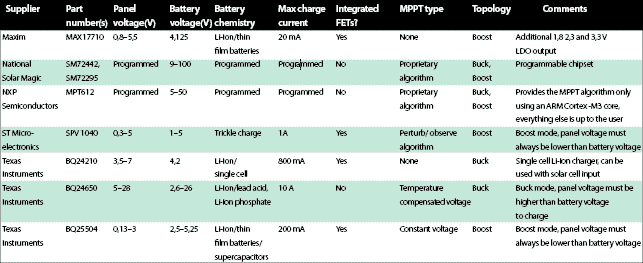

The potential for off-grid solar applications has grown to the point where semiconductor manufacturers have designed and brought to market specialised devices designed to maximise energy transferred from solar panels, often in combination with a battery charger circuit.

There are a number of factors that have an obvious impact on the productivity of solar modules. When light strikes a solar cell, the smaller the angle of incidence (from perpendicular), the more efficient the cell will be.

If the solar module does not have a motorised solar tracker to stay pointed directly at the sun, then the designer must take into account that the solar module will not be producing maximum energy.

For example, assume that the module is placed flat on the ground or on another surface parallel to the ground. Not only that, but it is placed in St. Louis, Missouri, in the winter, at noon, and the sun is at 37 degrees (or 53 degrees from perpendicular).

Best-case scenario, the solar module will produce around 55% of the total amount of energy it was capable of producing if positioned perpendicular to the sun.

Example power production

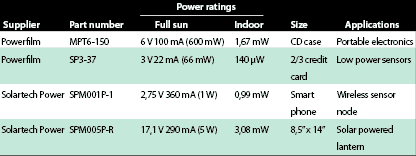

Let us look at some crystalline silicon and amorphous silicon solar modules and get a feel for their sizes and how much energy they will produce under various conditions.

Solar modules are rated for a certain power output; this is called their ‘DC nameplate rating’. Nameplate ratings mean irradiance of 1000 W/m² at 25°C at specific atmospheric conditions. Unless the system sees 1 kW/m² at 25°C, it will not produce the amount of power rated on the panel.

How much energy can the solar module be expected to produce from a given area? Solar module efficiencies for crystalline silicon are in the range of 13% to 18%. So, a 1 m² solar module will produce around 150 W. But, again, this is under test conditions of direct sunlight at 1 kW/m².

The following are some approximate size vs. output benchmarks:

* The amorphous silicon MPT3.6 (360 mW) is 7 x 13,3 cm, roughly the size of an external hard drive.

* The amorphous silicon 3 Vx28 mA (84 mW) module is about the size of a box of Tic-Tacs, or about 2/3 the size of a credit card.

* The 1 W crystalline silicon module is a little bigger than a large smartphone.

* The 5 W solar module is about the size of an A4 sheet of paper.

* A 230 W module is almost the size of a large door or the top of a large desk.

Indoor applications

What about indoor lighting? How much energy can be harvested indoors vs. outdoors? Office lighting seems bright enough – and indoor light does, obviously, produce a fair amount of visible light. So, the energy output should be about the same, right?

The human eye is magnificent. What the human eye perceives as ‘bright’ and certainly more than enough light to perform daily tasks, actually may have a very low energy level.

Sunlight ranges from 50 000 Lux to 150 000 Lux. Typical office fluorescent lighting ranges from 200 to 400 Lux – more than two orders of magnitude lower than direct sunlight. Logically then, the energy produced should be one to two orders of magnitude less than sunlight.

Indoor solar applications are possible; however, the output voltages of modules are significantly reduced, and the current generated is several orders of magnitude reduced.

A small, amorphous silicon solar module which produces VOC 4,5 V, ISC 48,5 mA in direct sunlight, would produce VOC 2,1 V, ISC 90 μA in an office environment at 250 Lux fluorescent lighting. So, microwatts of power are possible, but unless a large enough solar module is used, milliwatts are unattainable.

Solar applications with a very low active duty cycle and very low power consumption are possible in indoor applications, but most portable consumer electronics will need direct sunlight to generate enough power for a viable solar charging solution.

According to the difference in spectral responses between crystalline silicon and amorphous silicon solar cells shown in Figure 1, crystalline silicon does not work that well in indoor light, because indoor lighting produces very little light skewed to the IR part of the spectrum. For this reason, amorphous silicon modules are often preferred for indoor applications.

How to size a solar panel for a given application

There are a number of realities that must be considered. Nameplate ratings are at test conditions, which are ideal in many ways. Unless the system is designed to track the sun across the sky, maximum energy will not be harvested.

Is the system pointed at the sun at all? Is it shaded at times? Is it far north? Is it possible the solar modules may get dirty frequently? Is it located in a region where it is often cloudy? Is there access to direct sunlight or indoor light? All of these factors can significantly impact the amount of energy harvested by a solar module.

What is really needed is to calculate a budget for the amount of power required by the application and the amount of power that can realistically be produced by the solar module given its location and condition.

Power vs. voltage vs. batteries

One last thing to evaluate when choosing solar modules is the voltage required to charge the batteries. As already stated, there are a number of ICs designed to maximise power from solar modules, and to charge batteries of various chemistries.

These devices typically use either buck (input voltage is higher than output voltage) or boost (input voltage is always lower than output voltage) topologies. In choosing a solar module (or a conversion IC), this is an important consideration.

Solar is an abundant, free energy source for charging battery powered applications, however solar modules must be carefully selected and managed in order to harvest the maximum amount of energy possible.

© Technews Publishing (Pty) Ltd | All Rights Reserved