This is a continuation of an article which began in the Dataweek 1 May issue.

Considerations when loading the DUT battery charger

Mobile communications devices incorporate a wide variety of battery charging schemes. In production test the DUT charger is typically calibrated at high and low current levels for accurate full and trickle charge rates.

There are a variety of charge termination methods, all primarily determined by battery voltage. The DUT’s battery voltage sense needs to be calibrated to assure proper battery charging termination. Improper charger calibration can lead to exploding batteries when the device is in use.

To calibrate and test a mobile communications device’s battery charging system, the current needs to be drawn in reverse, out of the device’s battery port. The need for a separate load can be eliminated if the power supply can provide this function.

To emulate a charging battery, the system power supply needs to operate as a constant voltage electronic load by maintaining a stable positive voltage while sinking the charge current.

The voltage needs to be regulated at the remote test fixture. The power supply now needs to compensate for the reverse voltage drop in the wiring to the fixture.

1. Constant voltage loading capability

Mobile communications device battery charger operation

In battery charge mode, the mobile communications device must regulate the battery charge current and monitor the battery voltage to terminate when the battery is fully charged. Usually an external battery charger connected to the charger-input port on the device provides the power.

It is important that the DUT’s battery charging current and voltage circuits be tested and calibrated. Improper calibration can result in under- or over-charging, or worse, exploding batteries, when the mobile communications device is in charge mode.

The power supply emulating a charging battery

In contrast to the more usual situation of sourcing current, the power supply now needs to absorb, or sink, the battery charging current from the DUT, while also maintaining an accurate, remotely sensed, positive voltage at the DUT. The power supply is operating as a CV (constant voltage) electronic load.

Power supply considerations for CV load operation

CV load operation is needed to calibrate the DUT’s internal battery voltmeter so that the DUT can accurately sense the battery voltage low, high and charge termination points. The CV load voltage should be within 0,5% (20 mV for a 3,6 V battery) to calibrate the DUT charge circuit accurately. This allows margin for DUT inaccuracies and still has the necessary accuracy for proper battery charge-voltage termination.

The power supply’s current sinking and power dissipating capabilities and ability to maintain an accurate, remotely-sensed, positive voltage at the DUT are important features to check in the evaluation. Many system power supplies do not offer the capability of operating as a true CV load.

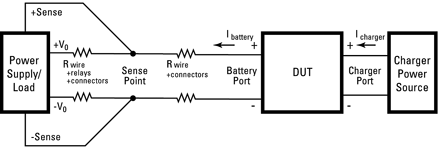

To evaluate CV load capability, refer to Figure 5. With an appropriate external battery-charging source connected to the DUT (an external battery charger or another DC source) the DUT can be placed into battery charge mode.

Because the main test system power supply is now sinking current, its remote sense must compensate for a reverse wiring voltage drop. The voltage at the power supply output terminals will be less than the remote sense voltage at the DUT fixture.

As a result, the power supply’s output will be operating over a wide range of voltage. At the upper extreme it may be nearly 8 V to emulate a fully charged 7,2 V battery pack under trickle charge. At the lower extreme it may need to operate near zero volts to emulate a discharged 3,6 V battery back under rapid charge, while compensating for the wiring reverse voltage drop.

Test system fault-mode consideration during battery charger calibration

For power supply remote sense operation, a separate pair of leads remotely senses the voltage to accurately measure and regulate the voltage at the DUT. Over time, the remote sense connections can become intermittent or open. Under these conditions most system power supplies revert to local sense operation, measuring and regulating the voltage at the output terminals.

The power supply will appear to continue to function properly as the measured voltage will be the expected value set. However, the voltage at the remote DUT will be in error. This will cause incorrect calibration, which can result in under- or over-charging, or worse, exploding batteries, when the mobile communications device is in use.

The test system designer should assess the power supply’s behaviour for this fault mode and take necessary precautions to prevent this from occurring.

Summary of important items for validating constant voltage load capability

* Maximum current sinking capability in CV load operation.

* Maximum power dissipation capability at high voltage.

* Over-power/temperature and reverse current limit protection.

* Output voltage-programming accuracy (< 0,5%).

* Maintains voltage regulation, especially at low voltage, end of relay and connector life, and maximum charge current, operating conditions.

* Broken voltage sense lead fault mode behaviour.

Validating these capabilities by reviewing specifications and making some performance verifications against specific application requirements, will assure proper CV load performance for accurate and repeatable battery charger test and calibration.

The Agilent 66111A, 66311B/D and 66309B/D DC sources feature CV load operation and uniquely provide open sense lead fault detection. The 66309B/D DC sources have a second output to provide power to the DUT battery charger input port.

Considerations when making DUT power measurements

The current measurement considerations when selecting a system power supply for mobile communications device testing are:

1. Talk-mode current drain measurements.

2. Standby-mode current drain measurements.

3. Off-mode current leakage measurement.

4. Battery charger current measurement.

Digital mobile communications devices transmit in short bursts, which conserves power between transmissions, thus extending talk time of the battery. Likewise, some digital devices also ‘wake up’ and listen for incoming calls in short bursts, again extending battery life. The resulting battery drain is continuous or pulsed current, ranging from milliamperes to amperes.

Longer talk and standby operating times are of primary importance to the user. Accurate current drain measurements are fundamental to assure proper battery life and operating time. The wide range and pulsed current drain characteristics can be challenging to measure accurately.

If off-mode leakage current is high, it can quickly drain the battery, leading to user dissatisfaction. Microampere level measurement is needed to test leakage current.

The DUT battery charger is typically calibrated at high and low current levels for accurate full and trickle charge rates. Milliampere to ampere-level, negative current measurements are needed to calibrate the device’s battery charge circuit.

A digital multimeter (DMM) is often added, along with a general-purpose power supply, to supplement the test system’s current measurement capabilities. This does not adequately address all these specialised requirements. Ideally, the system power supply alone would adequately address DUT battery current and voltage measurement requirements, eliminating the need for additional equipment. For this, the power supply must have several advanced measurement capabilities, specifically developed for the application.

1. Talk-mode current drain measurements

Talk-mode current drain is the most fundamental current measurement to assure the mobile communications device will provide adequate battery talk time. The pulsed current drain characteristic of digital devices can be challenging to measure accurately.

Pulsed current drain characteristics

The pulsed current drain characteristics are typically within the following ranges:

* Pulse periods from 5 to 100 milliseconds.

* Crest factors exceeding ten.

* Duty cycles from 10% to 50%.

* The pulse may have a high peak transient value to consider.

DC average current measurement considerations

Many times the DC average current drain measurement is in error, or erratic, because the pulse characteristics are not taken into consideration:

* The high crest factor may exceed the instrument’s capability. Usually the measurement is erroneously low, allowing defective product to be passed.

* The high pulse level but low average value dictates milliampere measurement accuracy over a full 2 to 3 ampere range.

* The relationship of pulse rate to the test equipment’s measurement window capability is overlooked. This most often results in jittering or erratic measurements.

For good accuracy and speed, a few factors need to be considered when selecting a product for making DC average current measurements:

* The measurement system handles high crest factors.

* The measurement window can be set to measure exactly one or more pulse periods when the pulse rate is known precisely.

* The measurement system can alternately provide accurate measurement when the pulse rate is not known precisely.

* Measurement accuracy is 1-3 milliamperes over a full 2 to 3 ampere range.

Most general-purpose power supplies cannot provide adequate accuracy due to the low DC average value relative to the large full-scale capability. Second, the short and fixed measurement window they have is not well suited for pulsed current drain measurements.

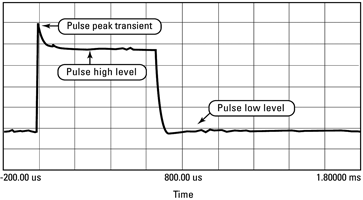

High level and peak transient current drain measurements

Testing the pulsed current drain’s high level and peak transient values augments qualitative screening of the DUT. Checking the high level ascertains transmitter power efficiency and quality. Checking the peak overshoot current enhances talk time test screening. A large peak current causes a corresponding large momentary battery voltage drop. Low battery voltage shutdown occurs sooner, reducing talk time.

It is unlikely to find these measurement capabilities on any general-purpose power supplies or most basic system DMMs. If they are featured, it should be verified that the capabilities are specifically suited for this application. This is easily done using a wideband AC/DC current probe and oscilloscope.

2. Standby-mode current drain measurements

Long standby-mode operation is extremely desirable, allowing the mobile device to receive incoming calls for many days before recharging the battery. Accurate current measurements down to milliampere current levels are required to assure adequate standby-mode operating time. Standby current may either be continuous or pulsed.

Continuous standby current measurement

Continuous standby current drain is typically tens of milliamperes, providing about two days standby mode operating time. The equipment should be able to measure the standby current drain at a few percent or better accuracy (<1 mA) to assure adequate DUT standby time performance.

Most general-purpose power supplies do not have adequate accuracy for standby current drain measurement due to its low value relative to the large full-scale capability.

Slotted-mode standby operation and pulsed current drain measurement

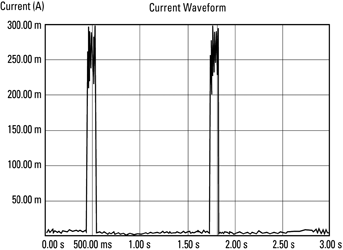

Some devices enter a ‘wake up’ state every few seconds for a short period to check for any incoming calls, drawing an active-mode current level. Between these periods the device drops back into a sleep state, drawing only millamperes of current.

This uses less average current than continuous standby operation, providing longer operating time. This is referred to as slotted mode, which is standard for narrowband CDMA format. Slotted-mode current drain is illustrated in Figure 7.

Considerations are the same as for talk-mode current drain. However, standby-mode pulsed current drain presents more of a challenge due to the longer periods, lower duty cycles, higher crest factors and lower levels of current involved.

Factors to consider in addition to those of talk-mode are:

* Sub-milliampere measurement accuracy in presence of high pulsed currents.

* Extended measurement window time and resolution of window time setting suited for slow pulse rates with very low duty cycles.

General-purpose system power supplies and basic system DMMs are not suited for directly measuring slotted-mode standby current, because of these factors.

3. Off-mode current leakage measurement

If off-mode leakage current is high, it can quickly and unexpectedly drain the battery, leading to user dissatisfaction as well as being systematic of a potential latent failure mechanism. Production testing off-mode leakage current catches random manufacturing and component defects. The off-mode current drain is usually under 100 microamperes.

The low-level accuracy needs to be considered when making off-mode current drain measurements. A separate, low-current measurement range with better than 10 microamperes accuracy is adequate for this measurement. Microampere level measurement is not a feature of general-purpose power supplies.

4. Battery charger current measurement

In most designs, the battery charger current is monitored and controlled by the mobile device itself. The DUT is usually calibrated at high and low current levels for accurate rapid and trickle charge rates.

Rapid charge rate current is typically under one ampere. Trickle charge rate current is tens of milliamperes. Measurement accuracy of 1% (< 3 milliamperes) should be sufficient for accurate battery charging calibration.

Providing the power supply has the ability to sink current and emulate a battery under charge conditions, it should then be verified that the power supply measures high and low charge rate negative currents to the required accuracy to properly calibrate the DUT. The accuracy required at the low level, relative to the full-scale capability, needs to be considered.

The wide range and pulsed current characteristics are challenging to measure accurately, even when using multiple pieces of equipment. Accurate current measurements during production test are fundamental in assuring proper battery life, calibration and quality of the mobile communications device.

The Agilent 66311B/D and 66309B/D DC sources feature a measurement system specifically for addressing all these specialised requirements without the need of additional equipment. The 66311D and 66309D also have a separate DVM input channel for independent voltage measurements at the DUT fixture.

| Tel: | +27 12 678 9200 |

| Email: | [email protected] |

| www: | www.concilium.co.za/test-measurement |

| Articles: | More information and articles about Concilium Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved