We’ve all heard the saying ‘a chain is only as strong as its weakest link’, and never has this been more relevant than when used to describe lithium ion cells connected in multi-cell battery packs.

When lithium ion (or lithium polymer) battery packs are built with multiple cells connected in series, cell balancing becomes an absolute necessity, both from a performance and safety point of view. In order to better understand this need for cell balancing, the workings of the obligatory protection circuit module (PCM), which is fitted to any lithium ion battery, must be understood.

The PCM is designed as an external safeguard whose primary function is to protect both battery and user from catastrophic failure, which could include explosion and/or fire. To ensure their safe usage, lithium ion cells are required to operate within very strict voltage parameters. Depending on the manufacturer and the exact chemical makeup of the cell, that voltage parameter could be anything between 2,5 V and 4,2 V per cell. The PCM is there to control these voltage parameters, and disconnect the cell or battery if they are exceeded.

This is very simple in the case of a single cell (or parallel connected battery pack) since the PCM is only monitoring the voltage of that single cell. However, multiple cells connected in series pose a completely new challenge. The multi-cell PCM is designed to monitor the voltage of each cell in the series string, independently. When any one of these cells exceeds the voltage parameters, the PCM will disconnect.

For example, in the case of a four-cell series connected lithium ion battery, during the charge cycle, should any one of the cells reach its upper voltage threshold, the PCM will automatically disconnect, thereby terminating the entire charging process, regardless of the state of charge of the other three cells.

Depending on the disparity in the voltages of the cells used in the multi-cell battery pack, this situation could potentially result in a battery pack never reaching full charge, thereby hampering the performance and expected runtime of the battery powered application.

Similarly, during discharge, should any of the four cells reach its lower voltage threshold, the PCM will again disconnect the load and terminate the discharge process, regardless of the states of the other three cells. In other words, a battery pack will only perform as well as its weakest cell.

The most obvious solution to this situation would be to ensure that cells are all equally balanced before assembling into a multi-cell battery pack (commonly known as ‘matching’). This is indeed true, but even the most reputable cell manufacturers have slight tolerances in their manufacturing processes, resulting in slight differences from one cell to another – even if they come from the same batch.

In addition, there are a number of factors which can affect lithium ion cells over their lifetime (uneven temperature distribution, for example) and lead to further disparity between the cells, and eventual imbalance during operation. In order to avoid this imbalance between cells, the use of cell balancing circuitry is highly recommended when designing multi-cell lithium ion battery packs.

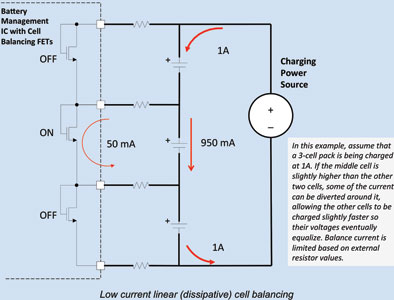

Cell balancing circuits are designed to divert some of the current around an almost fully charged cell whilst keeping the others charging at their full charge rate – thus, the ‘weaker’ cells get replenished at a higher rate than the stronger ones, until eventually they are all fully charged. In so doing, all cells within the battery pack will be allowed to reach full charge and should remain far more closely matched than they ever would have without a balancing circuit. This will result in optimal performance of a multi-cell battery pack.

When an application demands longer service life and optimal performance from a lithium ion battery pack, cell balancing should definitely be considered when designing the battery.

For more information contact Michael Rogers, Uniross Batteries, +27 (0)11 466 1156, [email protected], www.uniross.co.za

| Tel: | +27 11 466 1156 |

| Email: | [email protected] |

| www: | www.uniross.co.za |

| Articles: | More information and articles about Uniross Batteries |

© Technews Publishing (Pty) Ltd | All Rights Reserved