We often hear the phrase ‘form follows function’ but managing this as a successful design philosophy is not always that simple. The modern market not only demands products that function correctly, but products must be desirable and have the correct brand image.

Product aesthetics are often the biggest driving factor when it comes to the customer’s first-off value perception of a product.

This is where ‘Industrial Design’ becomes the magic ingredient when developing electronic enclosures. One need look no further than modern consumer electronics, like cellphones and tablets, to realise that design and brand image have become more important than specifications and clever ‘hidden’ features. This consumer approach has even spilled over into industrial markets where aesthetics and brand image were traditionally hardly a consideration.

A case study that serves to illustrate this point started when KM Product Design was approached a few years ago by an electronics company based in Centurion to assist with the industrial design of an interactive robotic gaming toy. Needless to say we jumped at the opportunity to get involved with this project, and it is possibly one of the best examples of where form had to meet function whilst retaining an absolute ‘wow’ factor.

Essentially this product is an example of an electronic enclosure with high levels of mechanical integration, that had to work perfectly and also had to look like something that escaped from every young boy’s (and most girls’) dream world. Our challenge was to manage this vision while ensuring that the unit not only mechanically functioned correctly, but was cost effective to manufacture and assemble.

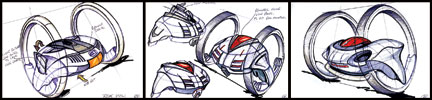

We started this project, as we do most, by developing conceptual sketches and basic 3D CAD models. This initial concept phase is most critical as this will form the foundation of all future developments for any project. It is hugely beneficial to have the industrial designer involved with the project from the very start. Our clients have seen the benefit of making us part of the team even during the initial brainstorming sessions defining the project brief. Sound industrial design cannot be added afterwards like a simple coat of paint; the full value-add through design has to be built in from the very inception of a product.

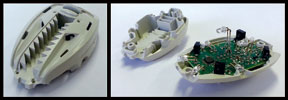

Working closely with this client’s electronic engineers, we defined the basic mechanical layout of the printed circuit boards and related components. This was one of the trickiest steps in the design process, as we then had to design the complete housing around this layout configuration.

The set of features that had to be included in this product gives some indication of the complexity of the design process. One of the biggest challenges was that the robot had to have a personality that had to be communicated through all aspects of the design.

Inside of Roboni-i are 12 infrared sensors, which it uses to sense its surroundings,’ talk’ to other robots and communicate with the included base station. It also features highly sensitive touch sensors at the front and back bumpers, allowing it to sense even the slightest physical contact.

With a full, 360-degree range of motion, the robot is incredibly agile. The user controls it using an ergonomically designed handheld controller, which communicates wirelessly (via Zigbee) with the robot. The controllers had to be capable of intelligent two-way communication and can display various aspects of the robot’s status, such as its level of ‘happiness’, battery life, current game mode and so on.

Using the included PC Command Centre program, the user can customise the way Roboni-i reacts to different stimuli. A drag-and-drop menu lets the user easily program the robot to reverse, spin around, crabwalk, flash its activity LEDs, and more.

Engineering refinement was the next step and some very interesting problems had to be overcome dealing with the complex drive train and mechanism for the hubless wheel system. Incorporating this principle in a mass produced plastic toy, without the use of complex ball bearings and expensive machined components, proved to be a fair challenge. Electronic control ultimately allowed the wheel motors to be independently calibrated so as to ensure that the robot runs straight, despite mechanical manufacturing tolerances.

Of specific interest was the infrared sensor system that allowed line-of-sight orientation with other robots and gaming objects. Special facets and angles had to be incorporated into the enclosure design so as to prevent any reflected infrared light from spilling into the sensitive IR receivers. This is clearly visible in the robot’s head design.

One of the goals that was set at a very early stage was to design the robot in such a way that all the working elements, including the main PCB, body sensors and complete drive train, are mounted on a single subassembly. This was done to ensure ease of manufacture and also to provide a means of testing the unit prior to enclosing all the components.

This principle made for a very complicated plastic chassis design, with all the fixing posts and geometry moulded in place so as to accept all the working components. The real challenge was not so much to get all of these points in place as it was to ensure that all this geometry is ‘mould friendly’ and doable in the mass production injection moulding process.

A number of other gaming objects had to be developed in conjunction with the robot. These enclosures all contained electronic componentry and formed part of the complete interactive gaming experience.

The enclosure development process is not finished when the drawings are handed over to the mould makers. Often, new product developments experience huge delays during the tooling phase due to miscommunication or simple oversight due to a lack of proper technical communication. Part of the turnkey service

that we offered to the client was to assist with the tooling and mould making process for all the enclosure components. The development process is only completed once the product is running smoothly off the assembly line.

This brief case study is typical of the challenges that industrial designers face every day in bringing sound mechanical design together with the art of aesthetic appeal. This unique combination of art and engineering creates desirable products that are much easier to successfully market.

For more information contact Peter Dreyer, KM Product Design, +27 (0)11 452 7999, [email protected], www.kmdesign.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved