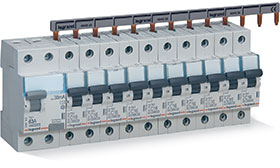

New to Legrand’s range of miniature circuit breakers (MCBs) is the TX³ series, designed for safe installation and maximum protection of people and property in modern commercial and residential installations.

TX³ thermal-magnetic circuit breakers have a C curve and are available in single-pole, 2-pole, 3-pole and 4-pole configurations. Units from 2 A to 63 A have a breaking capacity of 6 kA. This product is aimed at the mid-range market in its class, with limited cascading for intermediate commercial solutions.

New designs and materials used have been developed to allow air to flow freely between each device to prevent overheating. For increased safety there is no direct contact with live parts, even with the faceplate open. A wire guide flap avoids connection errors by preventing insertion of the wire behind the terminal.

These circuit breakers, with class 3 limitation, provide excellent short-circuit protection. Pin type comb busbars guarantee connection quality by eliminating the risk of short circuits and ensuring a reliable connection via the top or bottom of the device. By limiting the short-circuit energy released in cables, service life of components in the installation is significantly extended.

A bi-stable clip ensures easy positioning or removal of the circuit breaker on the DIN rail. Clear marking on the front panel ensures quick visual identification of relevant information such as product name, position of contacts (on/off), curve type, rating, breaking capacity and the limitation class.

Ergonomic holders protect customisable labels which are used to identify circuits clearly for rapid intervention in the event of an error. The shape of the screws and terminals ensures excellent mechanical withstand of wires and limits contact impedance, temperature rise and heat loss. Reinforced terminals allow tightening torques higher than in standard devices. For quick visual identification of the function, the circuit breaker has a black handle and the switch has a grey handle.

Residual current devices (RCD) in the TX³ range are available in 2-pole and 4-pole configurations, from 25 A to 63 A. AC types detect AC component faults and A types detect AC and DC component faults.

Legrand offers a wide range of control and signalling auxiliaries for flexibility in installations. These auxiliaries are used in conjunction with TX³ and DX³ circuit breakers to monitor and control circuits remotely in commercial installations. Components, which are available in 0,5 mm widths or 1 module wide, include auxiliary and fault signal contacts, shunt trips, under-voltage releases and motor driven controls.

Signalling auxiliaries (6 A to 250 V) have a wide range of functions, including an auxiliary changeover switch that indicates the position of the contacts of the MCB and a fault signalling changeover switch which indicates the opening on a fault. An auxiliary changeover switch can be changed to a fault signalling changeover switch and an auxiliary changeover switch and fault signalling changeover switch can be changed to two auxiliary changeover switches.

Current shunt trips are used for remote tripping of an MCB at the supply end and under-voltage releases have a time delay adjustable from 0 to 300 ms. A standalone release is used for positive safety tripping on the control circuit via a normally closed pushbutton. This facility prevents the device with which it is used from tripping if there is no supply voltage, yet retains the possibility of tripping via the control circuit for a minimum of 60 hours. This system is not suitable for the supply circuits of moving machinery.

Auxiliaries are equipped with retainer clips for quick, tool-free mounting on the left hand side of the MCB. Terminals with visible, accessible screw heads facilitate easy wiring. The arrow on the front of auxiliaries identifies the circuit breaker to which they are linked. Possible configurations are three auxiliaries per device, including one control auxiliary, as well as the insertion of the supply busbar.

For more information contact Legrand, +27 (0)11 444 7971, [email protected], www.legrand.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved