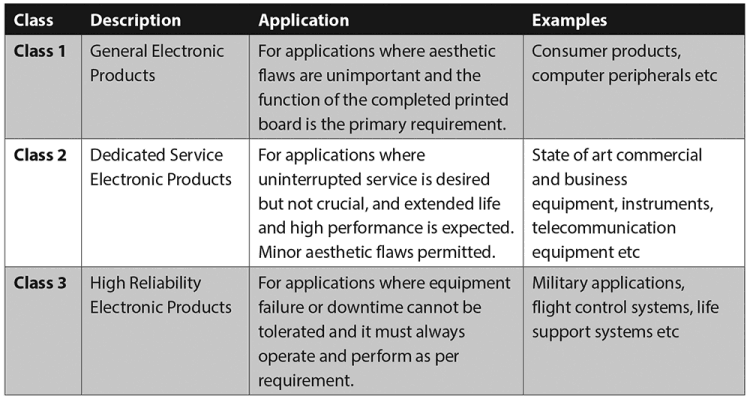

In the world of electronics manufacturing, the IPC standards provide critical guidance on the design, manufacturing, and testing of circuit assemblies. These standards are categorised into three primary classes, Class 1, Class 2, and Class 3, based on the intended reliability and functionality of the end product [see table 1].

Class 1 covers products with the least stringent requirements, typically used for consumer electronics with short life spans and/or non-critical functions. Class 2 addresses products where performance and extended reliability are desirable but not mission critical. Class 3, the highest tier, applies to products requiring consistent, high performance in demanding or harsh environments, such as aerospace or medical devices.

While these classifications have served the industry well for decades, the landscape of electronics usage and expectations is changing. Even devices classified under IPC Class 1, historically considered lower quality with limited reliability requirements, are increasingly expected to perform in environments previously reserved for Class 2 or Class 3 products. This trend raises an important question: Should the IPC standards be redefined to reflect these evolving expectations, particularly regarding cleanliness and durability?

The increasing complexity of ‘low-end’ electronics

Consumer expectations for electronics have drastically changed. Devices once considered disposable are now integral to everyday life. For instance, smart home devices, wearable health trackers, and IoT gadgets often fall under Class 1 due to cost constraints and limited life span. However, these devices frequently operate in challenging environments, such as high humidity, temperature fluctuations, and exposure to contaminants. Despite being classified as Class 1, users expect these products to function reliably for extended periods.

Take the example of a fitness tracker worn during workouts and outdoor activities. While the IPC Class 1 designation may not mandate rigorous testing or cleaning standards, the product is exposed to sweat, dust, and moisture. Failure in such a device, while not catastrophic, can erode consumer trust and damage brand reputation. This demonstrates a gap in the current classification system: Class 1 electronics are not held to the same cleanliness or durability standards as Class 2 or 3 products, yet they are often expected to perform in similar environments.

The role of cleanliness in reliability

One of the most critical aspects of electronic assembly reliability is cleanliness. Contaminants left on a circuit board after the reflow process can lead to failures through mechanisms such as electrochemical migration (dendritic growth and parasitic electrical leakage) or corrosion. IPC Class 1 does not require stringent cleaning standards because these products are assumed to have lower reliability requirements. However, as we have seen, the environments in which these devices are deployed often demand higher cleanliness levels.

For example, a low-cost IoT sensor deployed in an industrial setting may be exposed to dust, chemicals, and humidity. If the assembly process does not include post-reflow cleaning, residues such as flux activators or ionic contaminants from board and component fabrication, assembly processes, and humans can compromise the device’s performance. While the IPC Class 1 designation may allow for these residues, the user expects the sensor to function reliably despite its lower classification.

Harsh environments and the need for redefinition

The traditional view of IPC Class 1 products as inherently disposable and of lower reliability is increasingly outdated. Modern electronics, regardless of classification, are often used in harsh environments. These environments expose devices to extreme temperatures, moisture, and contamination, all of which can lead to failure if appropriate manufacturing standards are not applied.

To read the full study visit www.dataweek.co.za/ex/aqueous2025.pdf

| Tel: | +27 11 869 0049 |

| Email: | [email protected] |

| www: | www.mykaytronics.co.za |

| Articles: | More information and articles about MyKay Tronics |

© Technews Publishing (Pty) Ltd | All Rights Reserved