Design for manufacturing (DFM) is the process of designing products or components in such a way that it will ease the manufacturing process, so that it will result in a cost or time saving and/or improve the quality, repeatability and consistency of a product.

Why is DFM important?

In the highly competitive environment we find ourselves in today, every second or Rand saved can mean the difference between success and failure.

There are two ways in which this competitive advantage can be achieved. The first is the reactive way, whereby a manufacturer must cut corners and/or use inferior quality materials and parts in order to stay competitive. This approach usually has to be followed when the correct DFM principles were not followed during the design phase of a product.

A more proactive and prudent way of achieving a competitive advantage, without compromising quality, is to follow and apply the correct DFM principles in the early development stages of a new product. It is critical that these aspects are taken into consideration from the onset of a product because the further one progresses into the development phases, the more costly it becomes to implement changes.

What does DFM entail?

The main aspects that should be considered during the DFM process includes, but is not limited to:

1. Process.

2. Design.

3. Material

4. Compliance/Testing.

5. Environment.

Each of these aspects should be carefully considered, from the conceptual design stages of a product, with the end goal of optimising the manufacturing process throughout the entire manufacturing value chain.

Process

It is important to research different manufacturing processes and techniques and weigh up the pros and cons of each method when designing a product. It is also important to collaborate with all stakeholders to find the best solution for the specific product and anticipated volumes to be produced.

One such example is the various methods available for conventional through-hole soldering offered at Omnigo,

Design

When the product is designed, the manufacturing equipment specifications and limitations should be taken into account, as well as the pros and cons of each method to provide the best yield and most cost-effective solution.

An example of this is the panelisation of the PCBs to be compatible with the process. In a recent case, the design of the panel supplied by a client was not compatible with the de-panelisation equipment, which resulted in additional labour required to de-panelise the individual boards. Adding to this additional labour, 15000 units had to be partially populated by hand instead of using a fully automated machine build.

Material

Material and component selection can also have a major impact on the manufacturability and process compatibility of a product. Apart from process compatibility it can also play a major role in availability and lead time to source components.

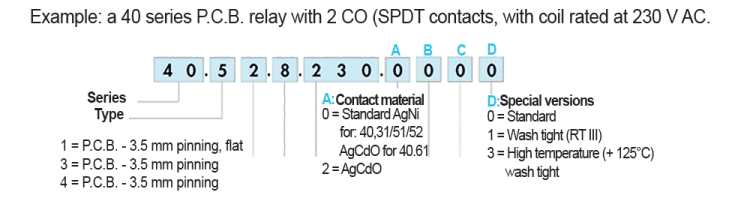

A typical example would be a relay’s numbering system

Compliance/Testing

It is also important to match the level of compliance, testing and inspection to the field of application of the product.

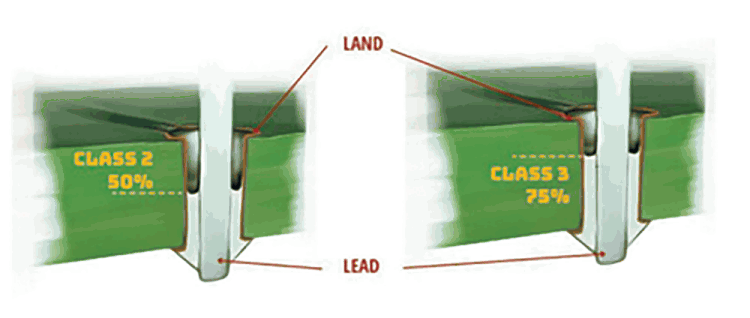

An example of this would be the IPC classification. In electronics manufacturing, printed circuit board assemblies are separated into three

As an example, the flow-through in the barrel of a conventionally mounted through-hole component should meet the requirements below for the different IPC classes.

Some measures that would be considered to ensure reliable and sufficient flow-through would be to design the PCB with adequate hole size to component pin size ratios and make use of thermal relief when connecting to large copper planes on the land area or internal layers in the PCB. To allow sufficient flow-through and from a process point of view, it is imperative to have adequate fluxing and bottom and topside pre-heating

Environment

It is important to match all aspects of the product manufacturing process to the environment that it will be used in as this could also add cost and complexity to the manufacturing process.

An example of this would be the decision to apply conformal coating to a product to protect against harsh environments. When it is deemed necessary for conformal coating, it is important to align the design, process, material selection and testing strategy with this requirement.

As an example, it is a pre-requisite for conformal coating to have the boards thoroughly washed and cleaned which by implication, also means that component selection and processes should not only be compatible with the conformal coating process, but also need to be compatible with a washing process.

It may also have an impact on the way a product is tested, and after-sales support is offered. The application of conformal coating makes reworks and fault-finding a lot more challenging due to limited access to test points and therefore, provision should be made for this as part of the test philosophy.

Conclusion

From the above, the importance of DFM is quite evident, and something often neglected during the inception phases of a new design. It is imperative that these principles are applied from the conceptual design phase.

| Tel: | +27 12 803 8218 |

| Email: | sales@omnigo.co.za |

| www: | www.omnigo.co.za |

| Articles: | More information and articles about Omnigo |

© Technews Publishing (Pty) Ltd | All Rights Reserved