In-circuit programmer for off-site production

17 May 2017

Manufacturing / Production Technology, Hardware & Services

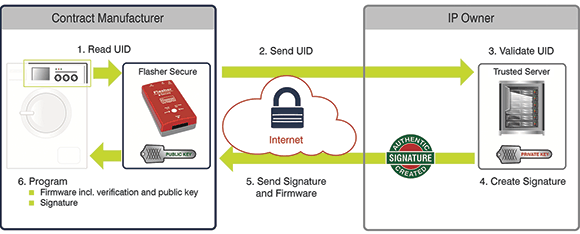

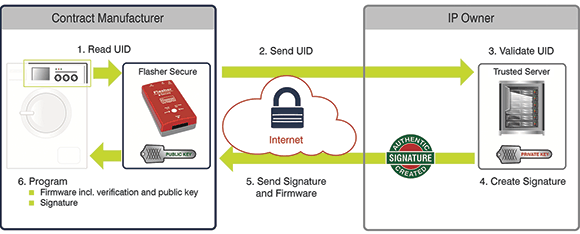

For high-volume production it is common to employ a contract manufacturer (CM). This setup introduces a new threat for the intellectual property (IP) of the original owner. To limit the risk of IP theft and overproduction, Segger developed the new production programming system Flasher Secure.

CMs have access to customer IP and large quantities of the components they are contracted to produce. It is essential that the original owner of the IP controls their IP and the production volume. Flasher Secure does both. To prevent counterfeit devices, the Flasher reads out a unique ID from the system it is going to program. This ID is sent to a server that is under physical control of the IP owner. This server validates the ID and determines whether a programming run is allowed. In this case, a signature is generated for the device. The signature is sent back to the Flasher which stores the signature inside the target device it programs. This method of secure programming is also in the best interest of the CM, as it can boast that the production floor will protect the customer’s IP.

Firmware running on the system, or an external application communicating with the system, can verify that the system is genuine. With an additional signature for the firmware, the bootloader in the system can also verify that the firmware is genuine and unmodified. If any of the above verification fails, the device stops working. As each signature is unique for each device, it is not possible to create a non-approved system by simply copying the firmware.

The signature generation uses a proven asymmetric algorithm where the private key is not accessible by anyone but the IP owner. This prevents attackers from forging a signature for a given ID. All communication between Flasher and server is encrypted and authenticated by a secure SSL/TLS connection to prevent unauthorised access. All actions are logged and accessible through an administration interface to provide as much transparency to the IP owner as possible.

The programmers are designed with multiple interfaces, making them easy to integrate into any production environment. In mass production environments, ATE or other production control units can access the Flasher for programming, including serial numbers and patch data.

For more information visit www.segger.com/flasher-secure.html

Further reading:

Outscale your competition

Manufacturing / Production Technology, Hardware & Services

Attendees will be able to explore the benefits of AMD Kintex UltraScale+ Gen 2 FPGAs in high-performance Pro AV, test & measurement, industrial, and medical applications.

Read more...

MTN SA Foundation drives youth pathways into the digital economy

Manufacturing / Production Technology, Hardware & Services

The MTN SA Foundation, in partnership with Helios Towers and Datacomb Development Hub, has launched the MTN–Helios Towers 12-month ICT Learnership Programme, a pathway that takes young South Africans from digital training into real workplace experience.

Read more...

Downstream demand, system reliability, and the expanding role of engineering-led distribution

Manufacturing / Production Technology, Hardware & Services

[Sponsored] As South Africa’s semiconductor demand continues to be shaped by downstream system deployment rather than upstream fabrication, the importance of engineering-led distribution will continue to grow.

Read more...

The impact of harsh environments and ionic contamination on post-reflow circuit assemblies

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

There is well documented historical proof that post-reflow circuit assemblies, when subjected to harsh environments, are particularly vulnerable to failure mechanisms, but modern electronic assemblies are far more susceptible to this phenomenon.

Read more...

Engineering copper grain structure for high-yield hybrid bonding in 3D packaging

Testerion

Editor's Choice Manufacturing / Production Technology, Hardware & Services

The way copper grains are sized and distributed forms the metallurgical foundation of hybrid bonding, enabling lower bonding temperatures, greater reliability, and stable grain structures throughout integration.

Read more...

Understanding solder dross: causes and control strategies

Truth Electronic Manufacturing

Editor's Choice Manufacturing / Production Technology, Hardware & Services

Dross formation is an inevitable consequence of wave soldering. It occurs when molten solder comes into contact with oxygen, forming metal oxides that float on the surface of the solder bath. Over time, this oxidation byproduct accumulates and must be removed to maintain solder quality and process consistency.

Read more...

Non-destructive techniques for identifying defects in BGA joints – TDR, 2DX, and cross-section-SEM comparison

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

This whitepaper reports the results of a comparison of the following techniques: TDR, automatic X-ray inspection (AXI), transmission X-ray (2DX), cross-section/SEM, and Dye & Pry.

Read more...

Implications of using Pb-free solders on X-ray inspection of flip chips and BGAs

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

With the move to Pb-free soldering, most of the attention has been paid to reflow temperatures, component compatibility, and reliability concerns, but the implications for inspection, particularly X-ray inspection, are equally important and often underestimated.

Read more...

The causes of solder balls in robotic soldering

Manufacturing / Production Technology, Hardware & Services

Solder balls (also known as solder splatter) are a major concern in many production sites as they may potentially cause shorts, leading to long-term impacts on product reliability.

Read more...

Material challenges for superconducting quantum chips

Manufacturing / Production Technology, Hardware & Services

To achieve the scalable and repeatable production of superconducting circuits for quantum technology products, players in the industry are leveraging semiconductor fabrication techniques.

Read more...