The trend towards small, well-designed and feature-rich consumer electronics devices is driving innovation across the whole electronics industry. Needless to say, the design challenges required of the power source appear to be coming back to basic physics.

The battery to power a portable device is chosen based on the functionality it has to support. Whether it is a 300 mAh, 600 mAh or even a 1000 mAh, there is a limit to the maximum current that a single battery can provide. This has the impact of potentially limiting the feature specification of the device you are designing.

Of course there are solutions to resolve that, but they are not easy, not elegant and require space. But surely, that is not something you want in a portable device. You only need higher power or sometimes a burst of power for starting a motor, for example. Or is that the case?

One recent innovation example is the use of an LED flash on smartphones or in compact digital cameras in place of a Xenon flash. In this case, the required current cannot be supplied by the battery alone, simply because you need a higher current than the battery can provide. For example, if you chose two LEDs to provide a flash capability on a mobile phone, you would need approximately 2 to 4 A for a time of about 33 to 40 milliseconds.

A conventional battery cannot do that, so a designer then has to decide how to power the flash. An option might be to use two batteries. But batteries are quite expensive and that would considerably increase the form factor, as well as representing an over-design for a peak-current assist to a set function.

So what is the solution? Recent advances in capacitor technology might provide a means of obtaining that peak power source. Supercapacitors, or electrical double-layer capacitors (EDLC) are essentially energy storage devices. As compared to conventional or advanced batteries, an EDLC has a high power density and a far longer cycle life. When first introduced, such devices were used mostly for low-power applications such as memory backup but recent electrochemical and packaging innovations have significantly improved the power capability at the same time as reducing the package size.

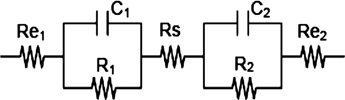

An example device is Murata’s EDLED (electrical double-layer energy device). Providing 2,75 V output, it has a flexible discharge ability of 500 μAh to 2 As and measures only 18,5 x 20,5 mm. Most importantly, such a device has a very low equivalent series resistance (ESR) making supercapacitors very attractive for specific power assist functions in small form factors. Typically an EDLC uses the phenomenon of storing an electrical charge in a double layer that occurs when a solid and a liquid come into contact.

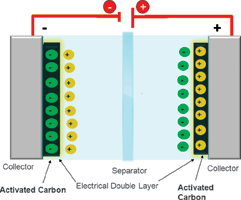

Figure 1 shows how an EDLC is made up of a separator, electrolyte, activated carbon and current collector. Activated carbon is almost always used as the electrode and because of its extremely high specific surface area and relatively low cost, ultra-high capacitances are possible within a small package size. Also, because there are no chemical reactions taking place, an EDLC can achieve a very high cycle life.

Having determined that an EDLC might be able to supply enough energy for a burst of power, the crucial decision for an engineer is to estimate how long the burst of power is required for. Up to 500 ms, you could use one or more EDLCs to achieve the demand. Going into detail for your design, determining the exact capacitance of the EDLC and the number of cells required depends on a number of factors. These factors include the maximum and minimum operating voltage of your application, the average current, the peak current, environmental operating temperature, the time that the peak is required for and, finally, the expected lifetime of the application.

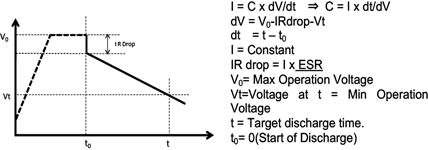

Figure 3 shows the discharge profile using a constant current model. Using the Murata EDLED device SingleCell type as an example, it allows a peak operating voltage of 2,75 V. 5 V for popular requirements can be addressed by the DualCell EDLED device. For an application requiring a higher operating voltage it is necessary to use multiple devices in series. However, this results in an increase in ESR. Alternatively, by putting cells in parallel the capacitance can be increased and this has the added advantage of lowering ESR.

EDLCs will find many more applications. One interesting potential application might be with POS terminals, the type we increasingly use to pay our bill in a restaurant. These portable devices require charging up to three times a day depending on workload. In the sense of the overall storage of energy, the batteries used in these appliances do not meet the energy profile expectations. By using EDLCs it might be possible to achieve more power efficient designs with less battery recharging.

To power other portable devices, in the past mainly Li-Ion battery technology could follow the increasing demand for high currents, but it might not keep track with the present speed of additional functionality and requirements for peak current demands. So micro fuel cells and other innovative energy storage technologies will become more popular in the future. For dynamic peak power assistance, supercapacitor technology is available today to help solve these problems in competitive and attractive small form factors.

| Email: | willem.hijbeek@tempetech.co.za |

| www: | |

| Articles: | More information and articles about Tempe Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved