The military and aerospace (Mil/Aero) world utilises products in harsh conditions, and the products must be able to properly perform. Because of this, many Mil/Aero manufacturers typically use full MIL-Spec products.

Severe Environment Testing (SET) is a Samtec initiative to test certain products beyond typical industry standards and specifications, many of which are common requirements for harsh environment applications/industries. Driven by demands for high functioning commercial standard interconnects, SET has proven beneficial in providing performance confidence, not only for rugged Mil/Aero industries and applications, but also for automotive, industrial and medical applications.

Samtec product offerings

Samtec is known for being a service leader in the industry, and service to the Mil/Aero industries is not any different. Each application has different levels of service requirements, budgets, testing requirements, and lead times. Because of these unique requirements, Samtec offers three different styles of products to meet the wide range of needs in the Mil/Aero world:

• Commercial Off-The-Shelf (COTS).

• Application Specific Product (ASP).

• Military/Aerospace Product (MAP).

Each style of product offering affords the customer different options. Product modification such as non-standard plating options such as up to 50 micro-inch gold can be ordered with ASP or MAP offerings.

What testing is performed?

SET was developed to bridge the gap from standard qualification testing offered on COTS products and a full MIL-Spec product. SET takes the standard qualification test, and builds on top of it to prove to the customer that Samtec products can withstand the rugged environments and conditions of the Mil/Aero world.

These additional tests include:

• Mating/unmating/durability.

• Mechanical shock/random vibration/LLCR and event detection.

• Temperature cycling.

• Non-operating class temperature.

• DWV at altitude – 21 336 m.

• Electrostatic discharge.

Samtec can also perform salt fog testing and conformal coating for its FireFly series. While these tests might not be exactly the same as a MIL-Spec qualification test, they afford the user the confidence that a COTS product will perform as needed in an application.

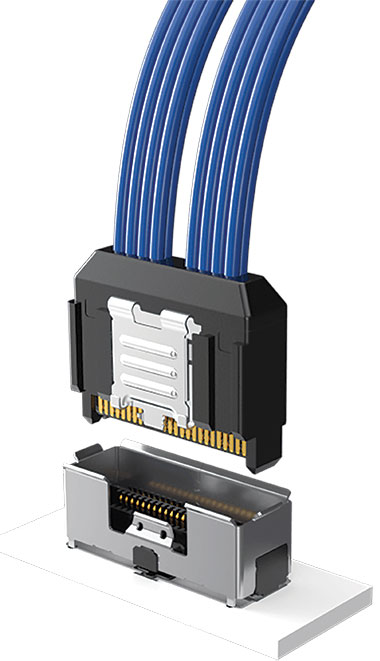

Rugged solutions and high-speed performance

Rugged situations require rugged solutions, and a majority of the time they still need to offer high-speed performance as well. Samtec offers rugged signal integrity solutions with speeds up to 12 Gbps PAM4 and extreme design flexibility to ensure performance reliability. Some of these rugged solutions include jack screws, positive latching, friction locks, retention pins, board locks, weld tabs, guide posts, and shielding.

| Tel: | +27 11 425 1400 |

| Email: | [email protected] |

| www: | www.spectrumconcepts.co.za |

| Articles: | More information and articles about Spectrum Concepts |

© Technews Publishing (Pty) Ltd | All Rights Reserved