It is common for many battery-powered devices to require a wide variety of charging sources, battery chemistries, voltages, and currents. For example, industrial, high end, feature-rich consumer, medical, and automotive battery charger circuits demand higher voltages and currents as newer large-battery packs are emerging for all types of battery chemistries.

Furthermore, solar panels with wide-ranging power levels are being used to power a variety of innovative systems containing rechargeable sealed lead acid (SLA) and lithium-based batteries. Moreover, some lead acid (LA) batteries found in solar applications are deep cycle batteries capable of surviving prolonged, repeated charge cycles, in addition to deep discharges. A good example of this is in deep sea marine buoys, where a 10-year deployment life is a prerequisite. Another example is off-grid renewable energy systems such as solar or wind power generation, where system up-time is paramount due to proximity access difficulties.

Even in non-solar applications, recent market trends imply a renewed interest in high-capacity SLA battery cells. SLA cells are inexpensive from a cost/power output perspective and can deliver high pulse currents for short durations, making them an excellent choice for automotive and other vehicle starter applications. Embedded automotive applications have input voltages >30 V, with some even higher. Consider a GPS location system used as an anti-theft deterrent; a linear charger with the typical 12 V input stepping down to a 2-in-series Li-Ion battery (7,4 V typical) and needing protection to much higher voltages, could be valuable for this application.

Deep cycle LA batteries are another technology popular in industrial applications. They have thicker plates than automotive batteries and are designed to be discharged to as low as 20% of their total capacity. They are normally used where power is required over a longer time constant such as forklifts and golf carts. Nevertheless, like their Li-ion counterpart, LA batteries are sensitive to overcharging, so careful treatment during the charging cycle is very important.

Current IC-based solutions cover just a fraction of the many possible combinations of input voltage, charge voltage, and charge current. A cumbersome combination of ICs and discrete components has routinely been used to cover most of the remaining, more difficult combinations and topologies. In 2011, Analog Devices addressed this problem and simplified this market application space with its popular 2-chip charging solution consisting of the LTC4000 battery charging controller IC mated with a compatible, externally compensated DC-DC converter.

Switching versus linear chargers

Traditional linear topology battery charger ICs were often valued for their compact footprints, simplicity, and low cost. However, drawbacks of these linear chargers include a limited input and battery voltage range, higher relative current consumption, excessive power dissipation, limited charge termination algorithms, and lower relative efficiency

An uncomplicated buck battery charger

Some of the tougher challenges a designer faces at the outset of a charging solution are the wide range of input sources combined with a wide range of possible batteries, the high capacity of the batteries needing to be charged, and a high input voltage.

Input sources are as wide as they are variable, but some of the more complicated ones that deal with battery charging systems are: high powered wall adapters with voltages spanning from 5 to 19 V and beyond, rectified 24 V AC systems, high impedance solar panels, car, and heavy truck batteries. Therefore, it follows that the combination of battery chemistries possible in these systems – lithium-based (Li-ion, Li-Polymer, lithium-iron phosphate (LiFePO4)) and LA-based – increases the permutations even more, thus making the design even more daunting.

Due to IC design complexity, existing battery charging ICs are primarily limited to step-down (or buck) or the more complex SEPIC topologies. Add solar charging capability to this mix and you open a variety of other complexities. Finally, some existing solutions charge multiple battery chemistries, some with onboard termination. However, up until now, no single IC charger has provided all the necessary performance features to solve these issues.

A buck IC charging solution that solves the problems discussed above would need to possess most of the following attributes:

• Wide input voltage range.

• Wide output voltage range to address multiple battery stacks.

• Flexibility – ability to charge multiple battery chemistries.

• Simple and autonomous operation with onboard charge termination algorithms (no microprocessor needed).

• High charge current for fast charging, large, high-capacity cells.

• Solar charging capability.

• Advanced packaging for improved thermal performance and space efficiency.

The LTC4162 battery charger

The LTC4162 is a highly integrated, high voltage multi-chemistry synchronous monolithic step-down battery charger and PowerPath manager with onboard telemetry functions and optional maximum power point tracking (MPPT). It efficiently transfers power from a variety of input sources, such as wall adapters, backplanes, and solar panels, to charge a Li-ion/polymer, LiFePO4, or LA battery stack while still providing power to the system load up to 35 V. The device provides advanced system monitoring and battery health monitoring.

While a host microcontroller is required to access the most advanced features of the LTC4162, the use of the I2C port is optional. The main charging features of the product can be adjusted using pin-strap configurations and programming resistors. The device offers ±5% charge current regulation up to 3,2 A, ±0,75% charge voltage regulation, and operates over a 4,5 to 35 V input voltage range. Applications include portable medical instruments, USB PD devices, military equipment, industrial handhelds, and ruggedised notebooks/tablet computers.

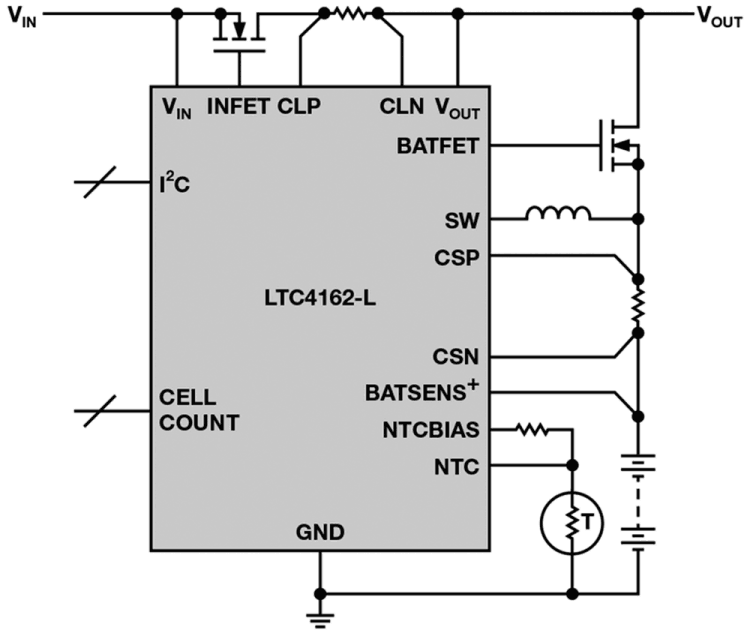

The LTC4162 (Figure 1) contains an accurate 16-bit ADC that continuously monitors numerous system parameters including input voltage, input current, battery voltage, battery current, output voltage, battery temperature, die temperature, and battery series resistance (BSR). All system parameters can be monitored via a two-wire I2C interface, while programmable and maskable alerts ensure that only the information of interest causes an interrupt.

The device’s active MPPT algorithm globally sweeps an input undervoltage control loop and selects an operating point to maximise power extraction from solar panels and other resistive sources. Further, its built-in PowerPath topology decouples the output voltage from the battery, thereby allowing a portable product to start up instantly when a charging source is applied under very low battery voltage conditions.

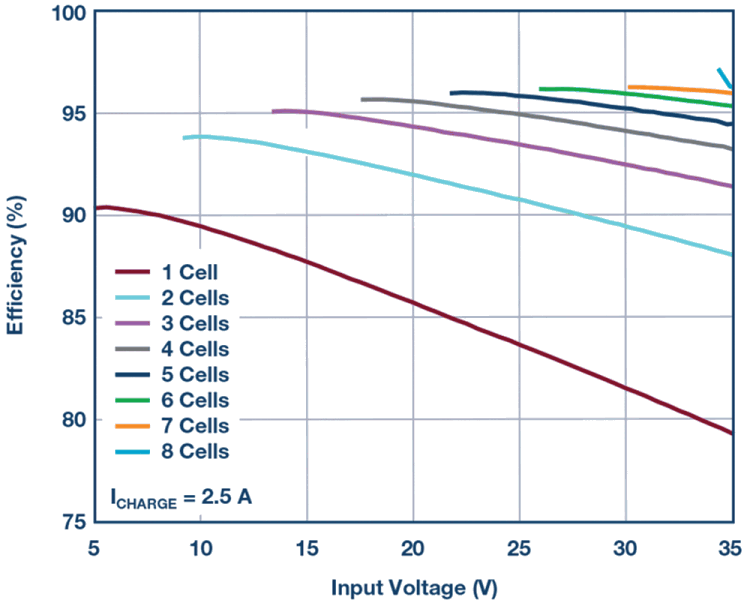

The LTC4162’s onboard charging profiles are optimised for a variety of battery chemistries including Li-ion/polymer, LiFePO4, and LA. Both charge voltage and charge current can be automatically adjusted based on battery temperature to comply with JEITA guidelines or be customised. For LA, a continuous temperature curve automatically adjusts the battery voltage based on the ambient temperature. For all chemistries, an optional die junction temperature regulation system can be engaged, preventing excess heating in space constrained or thermally challenged applications. Figure 2 shows Li-ion charging efficiency.

Finally, the LTC4162 is housed in a 28-lead, 4 x 5 mm QFN package with an exposed metal pad for excellent thermal performance. E- and I-grade devices are guaranteed for operation from -40 to 125°C.

What is higher current is needed?

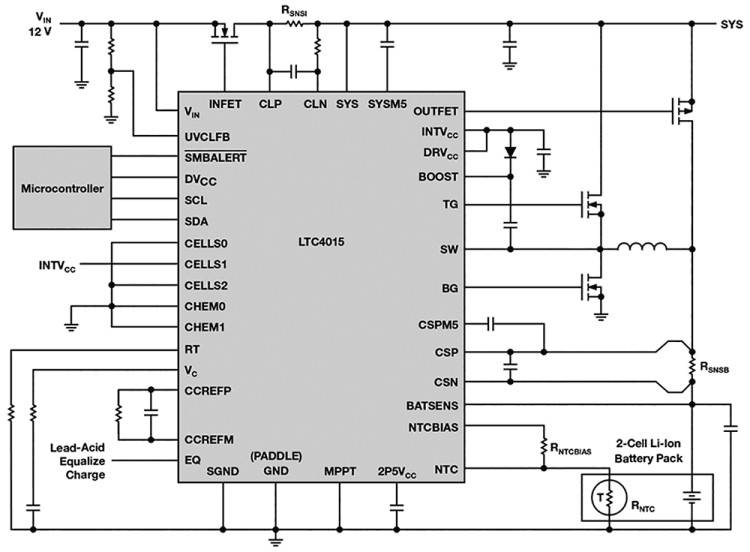

The LTC4015 is also a highly integrated, high voltage, multi-chemistry, synchronous step-down battery charger with onboard telemetry functions. However, it features a controller architecture with offboard power FETs for higher charge current capability (up to 20 A or more depending on external components chosen). The device efficiently supplies power from an input source to a Li-ion/polymer, LiFePO4, or LA battery.

It provides advanced system monitoring and management functionality, including battery coulomb counting and health monitoring. While a host microcontroller is required to access the most advanced features of the LTC4015, the use of its I2C port is optional. The main charging features of the product can be adjusted using pin-strap configurations and programming resistors.

The LTC4015 offers precision ±2% charge current regulation up to 20 A, ±1,25% charge voltage regulation and operates over a 4,5 to 35 V input voltage range. Applications include portable medical instruments, military equipment, battery backup applications, industrial handhelds, industrial lighting, ruggedised notebooks/tablet computers, and remote powered communication and telemetry systems.

Conclusion

Analog Devices’ newest powerful and full-featured battery charging and PowerPath manager ICs, the LTC4162 and LTC4015, simplify a very difficult high voltage and high current charging system. This greatly simplifies the designer’s task when it comes to medium-to-high power battery charger circuits.

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

© Technews Publishing (Pty) Ltd | All Rights Reserved