The global digital microscope market, valued at almost $6 billion in 2024, is expected to double to over $12 billion by 2034. Much of this growth is being driven by the electronics sector, where components from the tiny chips inside smartphones to the systems that ensure medical implants are defect-free, continue to shrink to levels of size and complexity once thought impossible.

While magnification technology has kept pace with demand, the wellbeing of the people behind the microscopes has often been overlooked. In the race for flawless inspection and assembly, technicians spend long hours in intense focus, which can lead to chronic strain, fatigue, and costly mistakes.

“Traditional microscopes force people into awkward positions, hunched over and straining their eyes, necks, and backs for hours at a time. This not only takes a toll on their health, but also impacts the quality of the work. In electronics manufacturing the risks extend far beyond physical health. Strained staff are more prone to errors, which can compromise both product integrity and business reputation. Even the smallest error can result in recalls or even lawsuits,” says Arno van der Walt, business development engineer at TANDM, the South African distributor of TAGARNO digital microscopes.

Far from being a nice-to-have, ergonomics is proving essential in digital microscopy. The link between ergonomics and sustained productivity, accuracy, and long-term business success is well-established.

In a study of inspectors using illuminated magnifiers called Luxolamps, operators reported high rates of eyestrain, headaches, and fatigue. After introducing simple ergonomic interventions, eyestrain dropped by 36%, headaches by 45%, and extremity fatigue by 28%.

Research shows that 78% of conventional microscope users experience neck strain from holding a slight head incline for prolonged periods. Over time, these awkward postures lead to musculoskeletal pain, fatigue, and even lasting injury.

Optical microscopes, while familiar and relatively affordable, are among the biggest culprits. Their fixed design forces users into static, forward-leaning positions, preventing neutral spine alignment and limiting accessibility to controls, resulting in lower productivity, higher absenteeism, and compromised work quality.

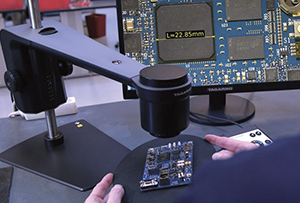

By contrast, digital microscopes like TAGARNO’s range are designed with people in mind.

Adjustable setups promote neutral posture, while the ability to capture, share, and document images in real time reduces workload and enhances collaboration, an invaluable advantage in precision-focused industries. These systems also allow users to inspect components on a large 50-inch 4K monitor, dramatically reducing eye and back strain while maintaining focus and precision.

This semi-automated process not only lowers the risk of human error by up to 50%, but also increases throughput, making it an indispensable tool in electronics, food production, medical devices, and even forensics.

The advantages of digital microscopy are clear in practice. Technicians at a Danish plant breeding company for example, previously relied on magnifying lamps and stereo lights, rigid tools that locked staff into uncomfortable postures for up to 37 hours per week, often resulting in stiff necks, headaches, and sick leave.

After adopting TAGARNO digital microscopes, staff reported fewer physical complaints, reduced absenteeism, and improved work quality. One technician even credited the system with helping her return to work sooner than expected after a serious head injury, thanks to the ability to work in a correct, comfortable position. Another highlighted how digital systems improved collaboration, making it easier to share findings and streamline workflows.

While local case studies are still developing, TANDM notes that South African companies in the electronics sector are already seeing comparable results, with early adopters reporting fewer complaints of strain, alongside measurable improvements in efficiency and error reduction.

“There is often hesitation because of the upfront cost, but the long-term return on investment is undeniable,” says van der Walt. “Reduced absenteeism, fewer errors, and improved staff wellbeing save companies far more in the long run. In an industry where mistakes can cost billions, these microscopes pay for themselves many times over.”

As South Africa positions itself within the global electronics market, investment in digital solutions is no longer optional. Digital microscopes not only place local companies at the forefront of precision manufacturing, but also align with international best practice in health and safety.

| Tel: | +27 87 092 0920 |

| Email: | [email protected] |

| www: | www.tandm.co.za |

| Articles: | More information and articles about TANDM |

© Technews Publishing (Pty) Ltd | All Rights Reserved