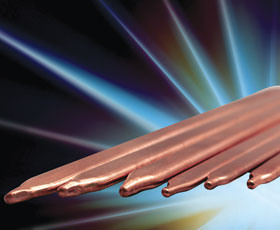

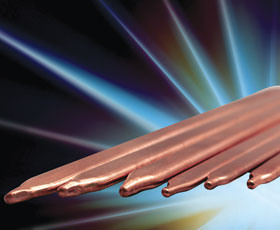

Round and flat profile heat pipes

8 October 2014

Circuit & System Protection

Advanced Thermal Solutions has introduced a series of copper heat pipes for transporting dissipated power away from hot electronic components. Thirty-three round and flat profile heat pipes are available to meet application needs, which transfer component heat to heatsinks with minimal temperature difference and distribute it efficiently across the length of heat spreaders.

Liquid in the heat pipe turns to vapour by absorbing heat and removing thermal energy from hot component surfaces. This vapour then travels to the cold end of the pipe where it releases latent heat and condenses back to liquid. The liquid returns to the hot interface along an internal copper wick to provide continuous thermal management.

The cold end of the copper heat pipe attaches easily to most heatsinks, providing effective cooling when a heatsink can’t be applied directly to a heat source. All heat pipes are easily hand- or machine-shaped to meet application needs, and they can be friction fit, clamped, soldered or adhesively attached.

Each model in the range has been characterised by ATS for both thermal resistance and maximum heat transport capability. The transport property is determined as a function of the working temperature and the pipe’s angle of inclination.

Every heat pipe consists of a sealed copper tube, internal copper wick structure, and distilled water as its working fluid. Round profile heat pipes come in lengths from 200 to 300 mm and diameters from 4 to 8 mm. Flat profile heat pipes range in length from 100 to 250 mm, widths from 8,2 to 10,5 mm, and heights from 2,5 to 4,5 mm. Weights range from 8 to 33 grams.

The pipes are effective in temperatures between 30°C and 120°C, and their lack of moving parts means they require no maintenance. They are available separately from ATS or in thermal solutions integrating the company’s widely-used Push Pin and maxiFLOW heatsinks. Other fluids and sizes can be accommodated with custom heat pipe designs.

For more information visit www.qats.com

Further reading:

Smarter protection without disruption

NewElec Pretoria

Circuit & System Protection

Designed for operations still running without integrated automation, NewElec’s retrofit-friendly systems let you upgrade performance and safety without overhauling your entire network.

Read more...

Circuit breaker for reliable, compliant protection

RS South Africa

Circuit & System Protection

Legrand’s low-voltage power distribution portfolio encompasses the DX3 range of miniature circuit breakers, designed to deliver dependable protection in residential, commercial and industrial installations.

Read more...

Reducing noise on power supply lines

Future Electronics

Circuit & System Protection

Murata has introduced the EMIFIL ESD Series Noise Filters, a breakthrough solution engineered for superior noise suppression and enhanced electrostatic discharge (ESD) protection.

Read more...

Clearing the Static: Fundamental principles of static control

Actum

Circuit & System Protection

Controlling electrostatic discharge in electronics manufacturing is essential with effective ESD programs built on six key principles.

Read more...

Electrical fire safety in lithium-ion battery rooms

Circuit & System Protection

Pratliperl is a non-combustible, ultra-lightweight aggregate that can be mixed with cement and applied as a plaster or screed to walls, floors, and ceilings.

Read more...

Clearing the Static: ESD training in the workplace

Actum

Circuit & System Protection

To protect sensitive electronic components, A structured, consistent, and sustainable ESD training program is essential.

Read more...

Protect your pumps – protect your profit

NewElec Pretoria

Circuit & System Protection

In South Africa’s demanding agricultural landscape, irrigation is not just an essential service – it is the heartbeat of farm productivity.

Read more...

Clearing the Static: ESD and installation: A durable antistatic solution

Actum

Circuit & System Protection

ESD flooring provides a reliable, long-term solution for managing static electricity by safely dissipating static charges through the floor to a designated ground point.

Read more...

Why wait to automate

NewElec Pretoria

Circuit & System Protection

NewElec’s initiative helps you gain operational visibility via HMI or PLC by retrofitting intelligent motor protection relays without replacing MCCs or rewiring the plant.

Read more...

Clearing the Static: Effectively control static in your workplace

Actum

Circuit & System Protection

Controlling electrostatic discharge in the workplace is crucial to protect sensitive electronic equipment from damage. Implementing an ESD control program involves various measures and tests.

Read more...