Electromagnetic interference (EMI) is caused by unintentional emissions from electronic equipment. Compared to natural sources of EMI, such as lightning and solar storms, engineers are more concerned about man-made, unintentional EMI emissions. Devices that emit these range from modern cellular communication systems and broadcasting systems to a host of electrical components, which generate burst, pulse, CW or modulated signals.

To gain global market access for their products, the manufacturers of electronic devices must comply with region- or country-specific EMC (electromagnetic compliance) directives and ensure that their devices are compliant.

The value of EMI pre-compliance testing

Reduce the risk of failing EMI compliance at the end of a project

Most manufacturers prefer to have their products certified by an authorised third-party service provider that is familiar with global standards and requirements. EMI compliance testing would ensure that products are completely certified.

However, EMI compliance tests are usually conducted at the end of project.

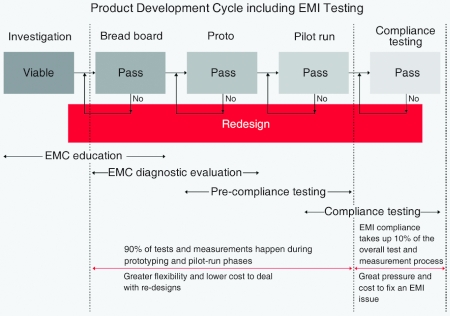

Referring to the product development cycle chart below, you can see that 90% of tests and measurements (including EMI diagnostic tests) happen during the prototyping and pilot run phases. EMI compliance tests, on the other hand, comprise only 10% of the process and occur at the end of a project.

EMI compliance test failures can be costly for a project team, time- and money-wise. Therefore, you should take the opportunity during the early stages of a product development cycle to minimise the risk of failing an EMI compliance test by conducting EMI diagnostic tests or pre-compliance tests.

Identify exact EMI sources

It can be difficult to tell where EMI failures are coming from since compliance tests themselves won’t tell you where exactly the source of the problem is. Radiated emissions may come from a USB port, a LAN port, the seam of a shield, a cable, a buffer, a clock or even a power cord.

You need to either troubleshoot yourself or obtain troubleshooting services from a lab or a third party. In this situation, near-field tests are the only way to locate such emission sources and are typically performed using a signal analyser and a set of near-field probes.

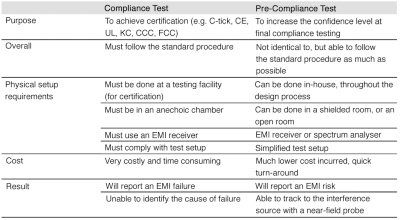

The functionality of an EMI receiver and a general-purpose signal analyser optimised for EMI emissions measurement applications is similar. EMI pre-compliance tests can be covered by either EMI receivers or signal analysers with basic EMI features such as CISPR 16-1-1 compliant detectors and resolution bandwidth. Signal analysers are usually less expensive than EMI receivers.

EMI compliance testing also requires conformance to a standard testing environment, which is hard for the majority of companies to achieve.

In short, EMI receivers enable you to do full compliance testing. They have been designed with all the compliance standards in mind and most organisations recommend using an EMI receiver for EMI applications.

On the other hand, general-purpose signal analysers can be used for pre-compliance testing. Signal analysers are a versatile tool and can be optimised to be used for EMI testing. If you are an RF engineer in the early R&D; product development phase, a signal analyser equipped with basic EMI features will provide just enough functionality for pre-compliance testing.

Conclusion

The advantage of running an EMI pre-compliance test with a signal analyser is that you can make a good estimation of the EMI performance of your new product and reduce the risk of failing EMI compliance at the end of a project.

| Tel: | +27 12 678 9200 |

| Email: | [email protected] |

| www: | www.concilium.co.za/test-measurement |

| Articles: | More information and articles about Concilium Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved