Lithium batteries can handle the extreme temperatures and severe mechanical shocks and stresses of demanding automotive environments.

Mounted on automotive windshields, road-toll transponders must withstand extreme temperature ranges. Powering these devices are bobbin-type lithium thionyl-chloride batteries. These batteries got the nod for the Ez-Pass system because they can handle the severe temperature cycles that characterise car interiors. Heat soak can hit 113°C (according to SAE) when parked, cooling down rapidly to room temperature. In cold weather, of course, the battery must handle cold soak and a rapid temperature rise. The design is also hermetically sealed, an advantage over nonhermetically sealed battery systems such as lithium manganese-dioxide coin cells. Such cells may breathe over large temperature ranges, with electrolyte possibly diffusing out of the battery while heating up, and moisture from the air potentially diffusing into the battery during cooling.

There are upwards of 10 million lithium batteries used in vehicles today. They power everything from electronics in toll-tag transponders such as the Ez-Pass system, to air-bag deployers, emergency mayday notification devices, GPS tracking equipment, and engine controllers.

The extended operating temperatures that are a claim-to-fame for lithium cells are possible because the battery chemistry uses no water and because battery materials are quite physically stable. Some lithium-based systems can operate at temperatures as low as -55°C and as high as 150°C.

How lithium batteries work

To understand the strong points of lithium cells, it is helpful to review their seven main components - the anode, separator, cathode, electrolyte, current collector, can and cover, and hermetic seal.

The anode is battery-grade lithium foil, pressed onto the inner surface of the cell to provide a mechanically sound and reliable electrical connection. The separator sits between the anode and cathode. Made of nonwoven glass, it prevents internal shorts while letting ions move freely between the electrodes. The cathode is a highly porous Teflon-bonded carbon-based powder. Thionyl-chloride cathodic reduction occurs on its surface under load. A solution of lithium aluminium-tetrachloride in thionyl chloride creates the electrolyte. A metal current collector provides the electrical connection between the porous carbon cathode and position terminal of the battery.

The cell can and cover are nickelplated, cold-rolled steel. The can withstands mechanical stresses over a range of service conditions. The positive cell termination of the lithium cell is insulated from the cell cover (which is the negative termination) by a glass-to-metal (hermetic) seal that uses compression-sealing technology.

Lithium cells often get specified for automotive uses because they offer benefits that are just not available from other battery chemistries. Lithium is an ideal material for battery anodes because its intrinsic negative potential exceeds that of all metals. Lithium is also the lightest nongaseous metal. Batteries based on lithium chemistries have the highest specific energy (energy per unit weight) and energy density (energy per unit volume) of all types. The high energy density is a result of lithium's high intrinsic potential, and the fact that lithium reacts strongly with water. Energy density of a battery depends mostly on cell chemistry and, to a lesser extent, on cell size and discharge rate. Generally speaking, increasing the cell size and decreasing the discharge current increases energy density.

Lithium is the lightest metal and has the lowest reduction potential (potential versus standard reference electrode). Therefore, batteries based on lithium chemistry are expected to have a higher energy density than other kinds.

That precludes the use of any aqueous (water-containing) electrolyte because lithium reacts with water. But that turns out to be a benefit. Because the oxygen and hydrogen in water dissociate in the presence of a potential above 2 V, cells using aqueous electrolytes have a limited voltage. Lithium cells, all of which use a nonaqueous electrolyte, have nominal open-circuit voltages (OCVs) of between 2,7 and 3,6 V. However, the use of nonaqueous electrolytes results in those cells having a relatively high internal impedance.

Comparing lithium chemistries

Lithium-battery chemistries differ in several important qualities. Critical considerations include nominal, minimum, and maximum voltage; initial, average, and maximum discharge current; the ability to handle continuous or intermittent operation; if intermittent, the amplitude and duration of minimum and peak current drains; service life; operating-temperature range; highest expected current at lowest expected temperature and permitted voltage-rise time to minimum voltage; and the storage duration conditions the battery can tolerate.

Under the broad category of primary lithium-battery types, several chemical systems are commonly in use. They are poly lithium (carbon monofluoride), or (CF)X-Li; manganese dioxidelithium (LiMnO2); lithium thionylchloride (LiSOCl2); sulfur dioxide lithium (LiSO2); and lithium iodine (LiI2). These systems derive their names from the type of cathode material they use. Poly (carbon monofluoride) cells have an OCV of 2,8 V and moderately high energy density. Cylindrical types are manufactured with a spiral-shaped cathode and crimped elastomer seals. Though generally safe, under extreme conditions the elastomer seals can fail before the case fails, letting the relatively reactive cell constituents escape.

Manganese dioxide-lithium cells are comparable to poly (carbon monofluoride) cells in their construction, energy density, safety, and OCV. But they typically have only about half the service life. Manganese dioxide-lithium cells are well suited to applications having relatively high continuous or pulsecurrent requirements, because the cell internal impedance is somewhat lower than for other types.

Lithium-iodine offers special safety qualities because it uses only solid constituents. The separator in a lithium-iodine cell can 'heal' itself if cracks occur. The major drawback to lithium-iodine is its high internal impedance, which limits its use to very low-drain applications.

Sulfur dioxide-lithium cells, used almost exclusively in military/aerospace applications, have lower energy density than manganese dioxide-lithium or poly (carbon monofluoride) lithium cells. Their service life and energy density are less than half that of lithium thionyl-chloride cells.

Lithium thionyl-chloride cells have the highest energy density of all lithium types. Service life is 15 to 20 years. These cells are best suited for applications having very low continuous-current and moderate pulse-current requirements. Their extremely long service life and low self-discharge rate make them ideally suited for long-term use in harsh environments.

Bobbins and spirals

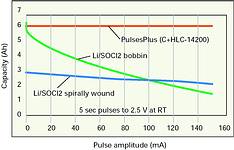

There are two types of lithium thionyl-chloride cells, bobbin-type and spirally wound construction. Spirally wound lithium cells deliver high current, but with less capacity and much higher self-discharge compared to bobbin-type cells. This is because spirally wound cells, also known as jelly rolls, have wound layers of lithium compared to bobbin-type which has only one layer. The larger the lithium area (anode), the larger the current draw and rate of self-discharge.

Bobbin-type lithium thionylchloride technology is particularly well suited for low-current applications because of its high-energy density, low self-discharge rate and 10-year-plus operating life. Bobbin-type lithium thionyl-chloride cells feature an operating temperature range of -55 to 150°C, high capacity, small size, and an ability to withstand broad fluctuations in pressure, temperature, and shock.

Such qualities have allowed these cells to serve in numerous roles where other kinds of batteries are not an option. One example is in tyre pressure monitoring systems. A group of German car makers now place lithium thionyl-chloride batteries inside each wheel on the rim. The batteries must be small and lightweight, last a long time, and be able to withstand extreme temperatures.

In one test on a mountain pass, a fully loaded car was driven for 45 min and saw extreme braking forces during that time. Brake disc temperatures hit 900°C and caused temperatures within the tyre to exceed 100°C. This was no problem for the lithium thionyl-chloride cells. They deliver a temperature range of -40 to 120°C, with a short term limit of 170°C.

Besides temperature fluctuations, the batteries see the mechanical shock and stress of a vehicle in motion. In the course of high-speed tests on the road and on dynos, lithium thionyl-chloride cells withstood over 300 km/h, mechanical shock 100 G half sine, and static centrifugal forces of 2000 G. Performing in these extreme conditions, the Tadiran T-4986/D is presently the only battery used by the German car industry for their tyre-pressure monitoring systems.

High-current pulse hybrid solutions

Over the past decade, there has been a dramatic rise in automotive applications involving high-current pulses, including automotive emergency-roadside assistance systems and GPS tracking and vehicle-safety monitoring systems. High-current pulse applications typically require a low continuous current (or no continuous current) coupled with high-pulse currents of up to several amperes for anywhere from a few seconds to almost 20 min.

Lithium thionyl-chloride batteries deliver the energy density to handle high-current pulse applications. However, these chemistries have drawbacks. Spirally wound cells lack enough capacity. And their comparatively high rate of self-discharge limits their long-term operation. Bobbin-type cells have ideal capacity and energy density, but suffer from two main drawbacks: severe passivation problems after storage at high temperatures and low current due to its design.

To overcome these obstacles, engineers at Tadiran designed a hybrid-lithium battery called Pulses-Plus which combines bobbin-type construction with hybrid-layer capacitors (HLCs). This hybrid lithium technology is currently finding use in GPS vehicle tracking and emergency call (Mayday) systems.

Reprinted with permission from MACHINE DESIGN, 02/21/02, a Penton Media publication.

For further information contact Tadiran representative in South Africa, Arrow Altech Distribution, 011 923 9600.

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

© Technews Publishing (Pty) Ltd | All Rights Reserved