The need of ever growing converter power has led to the development of Semikron’s new SKiiPPACK generation with compatible interfaces and dimensions to the present SKiiPPACK generation. The new product line will technically and logistically simplify the application of high power IGBT inverters up to the megawatt power range.

The objective was to maintain compatibility of the design. Additionally many improvements have been incorporated resulting in a higher power density and reliability. The SKiiPPACK power system can be divided into the semiconductor power section, the intelligent gate drive and the heat sink. This article details the achieved improvements.

Semiconductor power section

SKiiPPACK third generation features SKiiP technology and is based on a modular power section comprising a dual switch with third generation IGBTs and inverse controlled axial lifetime (CAL) diodes (Figure 1). The AC/DC terminals as well as the outer dimensions are compatible to the present family which simplifies transition. The new modular concept makes SKiiPPACK even more flexible since mounting is similar to the assembly of a MiniSKiiP or a SKiM power module.

The output power was increased by increasing the substrate and silicon area, the introduction of third generation IGBT silicon and by implementing high thermal conductive aluminium nitrite (AlN) ceramic material. The modular dual package is designed for a maximum output RMS current of 400 A, therefore increasing the current sensor capability by a factor of two. The cross-section of the AC/DC busbars has been increased. Table 1 shows the voltage and current ranges of the new types.

Spring contacts with proven long term reliability and ruggedness are now used for all electrical contacts between gate drive PCB and the power section, ie the gate, auxiliary emitter, auxiliary collector, thermal sensor and current sensor contacts. The new concept became feasible by the introduction of plastic pressure plates with steel inlay. As with the present SKiiPPACK generation, a spring pad is used to maintain the pressure contacts.

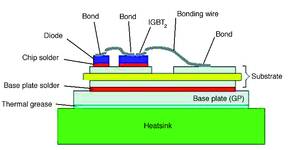

1. Power module (34 mm) with Al2O3 DBC substrate (0,38 mm) and copper baseplate.

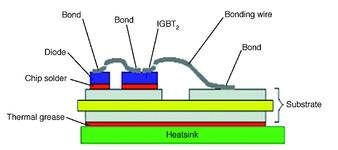

2. SKiiPPACK Power module with Al2O3 DBC substrate (0,38 mm); no baseplate (figures in round brackets).

3. SKiiPPACK Power module with AlN DBC substrate (0,63 mm); no baseplate (figures in square brackets).

Note: Figures shown in the table are the same if not indicated in brackets.

It should be noted that a silk screen printing should be used to attach the thermal compound layer to the heatsink. This procedure guarantees the reproducibility of the typical layer thickness. Furthermore, the introduction of AlN leads to an improvement of thermal cycling performance since the thermal expansion coefficients of AlN and silicon match better than Al2O3 and silicon. The thermal fatigue of the solder layer between the silicon die and DBC substrate is directly related to the difference of CTE in the incorporated materials.

The mismatch of AlN and copper on the other hand, is the reason why the introduction of AlN DBC is not feasible in standard power modules which have the DBC substrate soldered onto the copper base plate, since module lifetime will not be acceptable. Alternatively, an AlSiC base plate can be used instead of a copper baseplate which, however, has disadvantages in terms of thermal resistance and cost.

The base plate free system takes full advantage of the thermal conductivity of AlN without any disadvantage.

Intelligent gate drive

The SKiiPPACK third generation incorporates a gate drive with a single interface (DIN 41651) connector, compatible to the present SKiiPPACK generation. The gate drive contains full IGBT protection, current, temperature and DC-bus voltage sensing, error latch, interlock dead time, input switching signal pulse shaping and power on reset.

The Vcesat+ undervoltage monitoring is a new feature, and in addition, several improvements are incorporated:

* The 24 V power supply now has a wide capability from 12 to 30 V.

* The compensated current sensors' power consumtion per amp output current has been remarkably reduced.

* The IGBT protection has been enhanced by Vcesat monitoring, overcurrent protection, and by under-voltage lockout on the secondary side.

* Highly reliable direct spring contacts between power section and gate drive.

* The gate drive is now completely moulded and covered; the material has good thermal behaviour which leads to a temperature spreading of PCB hotspots.

Advanced cooling concepts

The application of AlN DBC substrate shows its full advantage when a liquid-cooled heatsink is used. Field tests have been performed on a dynomometer test stand with the six-pack 600 V SKiiP803GD061 with incorporated AlN DBC substrates mounted on a liquid-cooled heatsink in inverter application. This has been done with up to 380 A rms continuous phase output current rating. Switching frequency was set to 8 kHz, inlet coolant temperature at 70°C. In this case the output power density was increased by 90% in comparison to the present SKiiP PACK generation.

© Technews Publishing (Pty) Ltd | All Rights Reserved