To maintain one's standing in today's electronic production industry requires continuous focus of attention on its market and to react to the newest developing trends. Topics governing the present market conditions are: 'Lead-free soldering', 'fluxless soldering' or '400 µ-Technology'. They confront the electronic production industry with new challenges.

Thus, in the years to come, new and increasing efforts will be required in reflow technology. Considering the component and printed circuit board spectrum, one realises quickly that the reflow soldering systems will have to cover an increasingly large process window. In particular, boards and components exhibit generally increased mass and size differences.

As if that would not be enough, the equipment manufacturer will have to meet the demands of the new lead-free solder pastes head-on. Their melting points are substantially higher than those of the conventionally used tin-lead pastes. Consequently, capacity reserves in the respective machine technology are now an absolute must.

New dimensions in reflow soldering technology

SEHO's new machine concept - the Reflow Series FDS 6500 - offers a 30% greater process chamber volume. It is the flow-dynamic flexibility of the pressure, taper and bridge channels that has substantially optimised its process (Figure 1).

Compared to standard machines, SEHO's FDS 6500 features tangential blowers. Thus it heats the assembly and its components homogeneously and gently. Of special advantage is the tangential blower's lateral position, which distributes the process gases uniformly across the total conveyor width. Because of this all heat-sensitive parts, eg motors or bearings, etc., are located outside the machine's hot zone. This arrangement achieves a substantial reduction of heating-stress compared to systems where the blowers are vertically positioned and thus adds subsequently to a longer service life.

Furthermore, SEHO's FDS 6500 features slotted nozzles - not only in the soldering zone but also in the entire preheating zone. The special nozzle design creates a highly turbulent condition on the assembly's surface. This deliberately created gas turbulance on the printed circuit board - ie board-level-turbulence - has the advantage that drag forces encountered by laminar flow are effectively neutralised.

It also prevents the dislocation of any component - even at a high circulation velocity of the gas stream. This turbulence also excludes any shadowing effect. All this creates a homogeneous temperature distribution over the whole process width and results in low DTs on the assembly.

Principle of the process gas flow of the FDS 6500

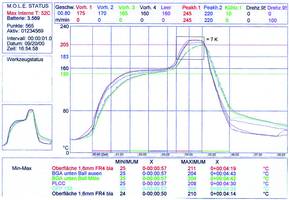

Any of SEHO's FDS 6500 with a heating zone length of at least 3,6 m features furthermore a double-peak, which permits a process especially safeguarding components (Figure 2).

This property is a particularly important aspect when processing lead-free solder pastes.

The second peak is set at an approximate 25K lower temperature relative to the first peak-zone.

Small components are heated to the maximum temperature already in the first peak-zone, in the second peak-zone they are kept steady at that temperature.

However, a high-mass component will be heated further in the second peak-zone - due to its lag-time.

This results in an extremely small delta DT.

Graph 1 shows a temperature profile - recorded with a SEHO FDS 6500 - with measuring points directly on the laminate, (FR4 blank, 1,6 mm), at an outer ball of a BGA, at a central ball of a BGA (ie always under the component), and at a PLCC and a QFP 132.

With this test a temperature difference of only 7K was recorded between hottest and coldest location!

Low overheads

SEHO's FDS 6500 features a unique nitrogen management system that consumes up to 30% less nitrogen - compared to standard machines in the market. Consequently, the savings are substantial.

Depending upon the density of population on the printed circuit board and the desired throughput, the average nitrogen consumption of SEHO's FDS 6500 is approx. 13 m3/h, at residual oxygen value of less than 50 ppm.

Considering a nitrogen purchase price of approx 25 Pf per m3 and operation during a 5 day-week with three shifts, annual savings of approximately DM 15,000 per machine may be realised.

Additionally, SEHO's FDS 6500 will realise massive savings in energy consumption. Depending upon the size and equipment of the individual machine it consumes only approximately 7-10 kW/h when being operated with nitrogen. Without nitrogen the energy consumption may drop around 4-7 kW/h. Obviously, the energy consumption is a function of the nitrogen consumption. This interdependency is caused by the nitrogen streaming to the outside thus carrying with it heat energy. The energy loss in the process has to be replaced by increased heating. The lower the nitrogen consumption, the lower the energy needed.

Precise measurements of the energy consumption of the FDS 6500 show that it consumes only insignificantly more during full production than under idle condition.

These extremely low consumption values are realised by the patented FDS 'Cassette-System' based on the tangential blowers and the nozzle system. Last but not least, the very efficient insulation of the whole process chamber is of great importance too. Furthermore, the so-called 'multifunctional' tunnels at the in-feed and exit of the machine ensure that only minor traces of oxygen may enter the process, thus assuring the nitrogen consumption to remain low.

Reduced maintenance

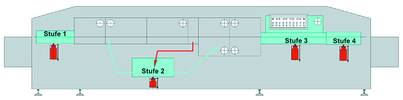

The four-stage condensate management system reduces, by its process gas cleaning, the contamination in the FDS 6500 to a minimum - and accordingly its maintenance overhead (Figure 3). Depending upon the throughput and process, maintenance cycles of more than 6 weeks may be realised. This compares favourably to standard machines in which the condensate residues in the process area must still be removed at least on a weekly basis!

From the first stage the condensing vapours are collected in a defined manner from the multifunctional cooling tunnels at the in-feed and exit of the machine.

In the second stage - the cleaning of the process gas in the heating zone - the contaminated gas is drawn off upstream of the peak-zone. It is passed by a condensate trap, cleaned and reentered in the pre-heating area and the peak-zone. The process gas is cooled only to such an extent which ensures the condensate to remain substantially liquid. This also ensures that at this point no unnecessary heat nor energy loss may occur.

A special feature of the system is that SEHO's FDS 6500 machines do not require any filters. Filters may gradually clog and thus cease to function effectively. SEHO'S FDS 6500, however, always ensures a uniform reflow process.

SEHO's FDS 6500 process gas cleaning principle uses physical laws of the flow properties of the condensate, removing it in a controlled manner from the process chamber and collecting it in provided polypropylene bottles (Figure 4). They may then be disposed with the condensate. The condensate trap is located in the lower part of the machine and easily accessed.

The third stage of the condensate management is integrated in the cooling zone. It is designed according to similar physical principles of the process gas cleaning as in the heating zone, ie this process uses the flow properties of the condensate too. Therefore, the cooling module does not need to be cleaned often.

Meeting the future

In addition to the capacity reserves for the actual processes, SEHO's FDS 6500 will meet also the future demands for its conveyor system. The system may integrate a single or dual conveyor, making possible up to four centre supports. Holding an equal footprint the FDS 6500 equipped with a dual conveyor may process approximately twice as many assemblies than with a single conveyor. Advanced precision controls ensure high operation reliability and the parallelism of the conveyor rails.

For further information contact Stephen Eglington, PEM Technologies, (011) 908 3030.

© Technews Publishing (Pty) Ltd | All Rights Reserved