Soldering is based on the ability of different metals to dissolve or diffuse into each other and to cause an electrical connection at lowest resistance and mechanical fixing. Flux is used to dissolve metal-oxygen layers on the surface of the different metals being connected with each other due to the dissolving of the tin into them.

Soldering tips

A soldering tip has two major tasks. The first is to transfer thermal energy with as low a loss as possible, and secondly, to carry the solder on the joint in combination with flux. Due to physics, the tip turns out to be a wearing part. And these tasks have to be done in combination with achieving long lifetime and at lowest cost.

To achieve excellent thermal conductivity, a soldering tip consists of a copper core (silver would be better, but is much more expensive).

The wettability of copper with solder tin is extremely good, which means the solubility of copper in solder tin is extremely high, causing the tip to be quickly consumed. The tip must be wettable to properly carry the heat and the tin on the soldering joint. Iron is also wettable with tin, but the solubility is far less. Unfortunately iron has a very low thermal conductivity and hinders thermal flow. The thicker the iron layer, the lower the heat transfer from the tip towards the soldering joint. The thinner the iron layer, the shorter the lifetime due to the solubility of iron in tin. Using other materials that are not soluble in tin will cause a non-wettable tip and poor soldering results.

Heating tips to high temperatures

The aggressiveness of the solubility of iron into tin increases with rising temperature. So also, the mechanical resistance of the tip's iron layer is reduced. When soldering, the tip is somehow always touching some part of the component and is in contact with the aggressive tin. Now, with lead-free soldering, the content of the tin in the solder is increased by 35%. This results in a 35% more aggressive solder towards the iron layer, simply causing reduction in life.

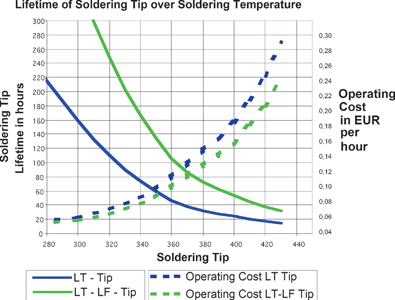

Now, standard tips have an average iron layer of 200 μm depending on the geometrical form. Weller's new LF tips carry an optimised layer of twice as much iron. More iron would cause a lower heat transfer and hinder the soldering process. Influence of the temperature to the lifetime and iron layer can be seen in Figure 1.

A general recommendation is to use a tip as large as possible, and if necessary, to improve the process by using a thinner solder-wire. For lead-free solder, the adjusted soldering temperature at the station should be in the range of 340-360°C, depending on the geometry of the tip. For further enhancement of tip lifetime 'Stop+Go' stands should be used.

| Tel: | +27 11 704 3020 |

| Fax: | 086 555 0111 |

| Email: | [email protected] |

| www: | www.ama-sa.co.za |

| Articles: | More information and articles about Allan McKinnon & Associates |

© Technews Publishing (Pty) Ltd | All Rights Reserved