Rework and repair of electronic components is still a must for production managers of modern factories; even the steadily growing production quality of high-precision machines and well established quality assurance procedures cannot completely compensate the necessity of rework and repair.

Thus, it is essential to make rework procedures more reliable and safe. However, the time is past when SMD components were recklessly desoldered from highly-integrated circuits by means of a modified hot air gun.

Repeatable rework quality ranks high for those responsible. According to the motto: If repair is necessary, then it must be quick, economical and reliable for the long term. So, only inveterate users of hot air fans will continue to use them. But for those looking for a gentle and high-quality system that also guarantees safe processes, there are a few systems that meet these requirements. Recently these systems have been established on the market in the field of high-channel SMD rework - especially now since BGA components have gained acceptance.

If one watches the market for such rework systems closely, one will realise that the manufacturers' R&D departments make much effort to meet the demands for a rework soldering process quality that corresponds with that quality achieved with a production line. There are high requirements:

* Rework soldering profiles within a determinable temperature range.

* Repeatable process quality on a constantly high level.

* Safe documentation of soldering results and process parameters without requiring any expert knowledge.

If these requirements are met, one keeps the quality principles and, at the same time, guarantees reliable production processes. Apart from fully automatic systems, which sometimes have complex programs, many manufacturers rely on semi-automatic systems to maintain process safety as well as flexibility which is important to the operator. The trend is that customers look for systems being easy to operate while also guaranteeing high-quality soldering joints. Technical efforts concerning hardware, software and maintenance must also be kept at a reasonable level.

Challenge: Technologies

However, the original competition between the technologies remains. The way in which heat is transferred to the component differs, of course, depending on whether radiators or hot air systems are used to deliver the process heat. With some hot air systems problems like uneven heat distribution, large space requirements of the nozzles as well as unwanted heating of neighbouring components remain open issues.

For years, Ersa has successfully been using infrared radiators over the long and medium wave infrared spectrums. This is why it was able to take a decisive step further towards process safety, which was only possible because the IR technology was maintained and optimised. The keyword being: 'reflow-process-control (RPC)'.

What lies behind this is the simple and obvious idea that the repair procedure can be facilitated by using the same technique used for decades in hand soldering, namely the observation of the soldering spot during the soldering process. To observe soldering joints of SMDs, especially those of BGAs and similar components, certain requirements have to be met.

First of all, the components and soldering spots may not be hidden by parts of the rework system, such as hot air nozzles. Further, due to today's grids, the area to be observed must be magnified for visualising reflow at the joint. This requires sufficient illumination of the relevant components.

With this technology, the heat radiating systems allow visual sight to components and a comfortable working distance between PCB and heat source, since they do not require nozzle enclosing parts. Using a high-resolution zoom camera equipped with an LED ringlight and a joint to swivel the camera in all axes, one can obtain descriptive images in virtually every case.

The informative value of temperature measurements

The weak spot in rework is temperature measurement at the soldering joint. During the actual rework process, temperature measurement directly at the soldering joint is usually impossible. Contacting heat sensors such as thermocouples do not really show the temperatures which are important for the creation of a soldering joint. And precise temperature measurement directly at the joint by using non-contacting heat sensors is, at least, impossible with the construction of hot air systems. The idea to determine the actual soldering joint temperature from a value measured with a noncontacting sensor has not existed so far. This gap is now filled by the RPC concept.

Precise temperature measurement by adjustment of visual and sensory data

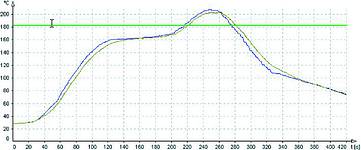

Thanks to Ersa's extensive work in the field of visual inspection of soldering joints, the knowledge gained on the creation of hidden soldering joints like those of BGAs and CSPs can immediately be used for the rework processes. The first source of information is the camera picture of the soldering joint or its immediate vicinity. (Figure 2). The second source of information is the surface temperature measured with the non-contact temperature sensor. It can further be taken for granted that one knows the melting temperature of the solder alloy used. The melting temperature of the common solder (Sn63Pb37) is 183°C. As lead-free soldering is the future, tin-silver alloys are also very important. Their melting temperatures range between 215°C to 220°C. The melting temperature is freely selected at the rework system depending on the solder used.

By means of the camera the operator watches the reflow of the solder joint on a monitor and adjusts, as soon as the solder melts, the displayed temperature of the sensor to the actual melting temperature at the soldering joint. In this way the operator ensures that the temperature is high enough to create a long-lasting, good soldering joint at the soldering spot. As per this temperature calibration it is guaranteed that the system will then always process such boards in the same manner - forming the basis for repeatable processes.

For every new job then, the operator can quickly find the best process parameters based on adjusting the temperature sensor information to the visual camera information. Thus, it does not matter whether many circuit boards are of the same type, as in rework, or always different, as in repair environments - the system is perfectly suited for both applications.

For desoldering tasks the system offers another technical highlight: As soon as the solder is liquid, the component is automatically lifted off the PCB by a spring-loaded vacuum pipette. At the same time, the temperature measured by the sensor and the actual melting temperature at the soldering joint are adjusted. Now the system 'knows' the actual melting temperature at the soldering joint and can use this information for the soldering process. The system establishes a new parameter set for this component type and will treat other components of the same type as per this parameter set.

Stored repeatability

Once a temperature profile is stored it ensures repeatable soldering processes with the same component types at constant ambient conditions. Corresponding PC software allows storing the profiles for each component. All process parameters are stored together with the component temperatures reached during desoldering. The rework system is fitted to the soldering job within seconds simply by downloading the process parameters. The temperatures reached during the soldering process are stored beside system and calibration data and thus completely meet the requirements for comprehensive process documentation, which rounds off the system.

Rework system solutions

Based on this RPC concept of visualising the reflow, Ersa developed a complete product line. The IR 550 A Rework System, combines IR radiator technology and non-contacting temperature measurement in processor-controlled temperature matches. To visually control soldering joints, modern motor zoom cameras and powerful LED light sources are available. The established fine pitch placer completes the rework system. A high-quality camera together with the high-contrast LED illumination forms the basis for deceptively simple component placement as well.

The systems are of modular design and can be arranged according to the customer's particular requirements: for newcomers to professional reworkers that require high-end solutions with visual process control, precise placement and controlled high-end soldering.

Summary

Despite all the efforts of the manufacturers, it will be impossible to avoid rework of electronic components in future. Ersa will stick to the principle of focusing on solutions for every budget, meeting the requirements for repeatable and high rework quality in electronic production. For the user's benefits, RPC technology offers unique rework systems in many respects.

| Tel: | +27 11 609 1244 |

| Email: | [email protected] |

| www: | www.zetech.co.za |

| Articles: | More information and articles about ZETECH ONE |

© Technews Publishing (Pty) Ltd | All Rights Reserved