Solder inspection system offers high magnification for accurate inspections

25 February 2004

Manufacturing / Production Technology, Hardware & Services

Incorporating the versatile Windows 2000 interface, Omron's VT-WIN II PCB solder inspection system can be used either in-line or off-line, for rapid, accurate identification of a variety of circuit board assembly defects. A zoom lens allows multiple magnifications down to 10 microns per pixel. According to the company, the VT-WIN II's magnification is the highest in the industry, allowing it to accurately inspect 0201 components. In addition, with its high speed digital camera and high speed motion control, it is also one of the fastest inspection systems around - and twice as fast as the previous VT-WIN model.

Figure 1. The VT-WIN II offers advances in solder inspection, component fault detection and process speed that gives manufacturers a competitive edge in productivity, waste reduction and quality control

Major improvements with VT-WIN II are: angled-view inspection to detect lifted leads on gullwing devices and heel fillets on SOJ and PLCC devices; industry-leading algorithms to accurately inspect lead-free solder; four times the inspection area and twice the speed; automatic colour extraction tool and other teaching aid functions dramatically reduce setup time.

First introduced in 1996, the original VT-WIN revolutionised in-line PCB inspection with a patented Colour Highlight System and colour image processing. Omron's VT-WIN II handles a variety of PCB styles, increasing production flexibility. The Colour Highlight System enables instant, consistently accurate recognition of solder quality, wettability and correct component placement. Accuracy is also enhanced through the system's position self-adjustment function. This function enables the system to automatically adjust solder land size inspection area allowing simplified programming of varying land sizes.

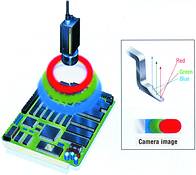

Figure 2. Omron’s Colour Highlight System projects red, green and blue light onto the PCB at different angles. The camera captures these reflected colours, producing a two-dimensional image that conveys three-dimensional information that allows the VT-WIN II to detect minute flaws that would commonly be missed

The Colour Highlight System uses a multicolour LED light source to project red, green and blue light onto the PCB at different angles. The camera captures these colours as they reflect off the board's surface, producing a two-dimensional image that conveys three-dimensional information. This image allows the VT-WIN II to detect minute flaws that would ordinarily be missed. Compared to gray-scale inspection methods, where solder fillet image settings are defined with numerical values for brightness and contrast, this process is significantly easier, reduces errors due to misinterpretation of data or colours, and ultimately reduces start-up time.

Another aspect of the VT-WIN II's functionality is its optical character recognition (OCR) capability, in which it distinguishes correct component values, thus preventing incorrect assemblies. The system also has advanced algorithms that enable proper inspection of leading technology processes such as lead-free solder. The software, which is programmed via CAD placement data, incorporates intelligent algorithms to reduce operator programming time. Omron's graphical user interface allows parameter settings to be defined via a 'point-and-click method' rather than requiring numerical values to be entered.

For more information contact Hawker Richardson, 011 792 2766.

Further reading:

20 years of precision, progress and purpose – the Jemstech journey

Jemstech

Editor's Choice Manufacturing / Production Technology, Hardware & Services

Twenty years ago, Jemstech began as a small, determined venture built on technical excellence and trust. Today, it stands among South Africa’s leading electronic manufacturing service providers.

Read more...

An argument to redefine IPC class definitions for class 1, 2, & 3 electronics

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

One of the most critical aspects of electronic assembly reliability is cleanliness. Contaminants left on a circuit board after the reflow process can lead to failures through mechanisms such as electrochemical migration or corrosion.

Read more...

Large platform stencil printer

Techmet

Manufacturing / Production Technology, Hardware & Services

GKG’s large platform stencil printer, the P-Primo, is designed to meet customer’s ultra-large printing requirements by supporting board dimensions up to 850 x 610 mm.

Read more...

Press-fit component inspection

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

In electronics manufacturing, optical inspection of press-fit components is crucial to ensure the quality, reliability, and performance of the final assembled product.

Read more...

A new era in wire bond inspection

Techmet

Editor's Choice Manufacturing / Production Technology, Hardware & Services

Viscom is developing a 3D wire bond inspection system that incorporates substantially improved sensors, a high image resolution, and fast image data processing.

Read more...

High-speed, high-resolution material deposition system

Manufacturing / Production Technology, Hardware & Services

ioTech recently unveiled the io600 inline digital laser material deposition system at productronica 2025.

Read more...

Mycronic’s MYPro A40 pick-and-place solution

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

Mycronic’s MYPro A40 pick-and-place solution, equipped with an MX7 high-speed mounthead technology, increases top placement speeds by 48% over the previous generation.

Read more...

Why ergonomics matters in digital microscopy

TANDM

Manufacturing / Production Technology, Hardware & Services

While magnification technology has kept pace with demand, the wellbeing of the people behind the microscopes has often been overlooked with technicians spending long hours in intense focus, leading to chronic strain, fatigue, and costly mistakes.

Read more...

From ER to effortless: The 15-year journey of Seven Labs Technology

Seven Labs Technology

Editor's Choice Manufacturing / Production Technology, Hardware & Services

What started as a business likened to an ‘ER’ for electronic components has today grown into a trusted partner delivering kitting services and full turnkey solutions – taking the effort out of electronics and helping customers truly ‘Move to Effortless.’

Read more...

Choosing the right electrical component supplier for reliability and scale

Rebound Electronics

Manufacturing / Production Technology, Hardware & Services

Selecting the right supplier extends beyond cost or delivery time; it is about ensuring long-term reliability, compliance, and scalability.

Read more...