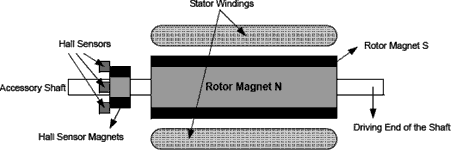

A brushless DC motor (BLDC) system is one of the most popular motor types used in the market (besides stepper motors, DC motors, etc). The internal structure of BLDC motors consist of a permanent magnet located at the rotor and the windings located at the stator.

Unlike DC motors, the stator windings are required to energise in sequence to enable smooth commutation within the BLDC motor. As a result, electronic and sensor feedback is required to make the location of the stator windings known with respect to the rotor magnet. A BLDC motor can be configured to be 2- or 3-phases regardless of the number of stator windings and the number of pole-pairs which are also configurable.

Conventional BLDC motors use the Hall sensor as a feedback system to get the location of the stator windings with respect to the rotor. This information is used to enable the electronics system to determine which winding to energise, in order to commutate the motor.

The Hall sensor is normally embedded into the stator or the non-driving end of the BLDC motor. An additional printed circuit board (PCB) is required to place the Hall sensors that are aligned with the rotor magnet. For servo applications, required position feedback is provided by an additional position encoder, which significantly increases the complexity and cost of the entire motor package. An example of the BLDC motor is illustrated in Figure 1.

To solve this problem, equivalent Hall sensor commutation outputs are integrated into the position encoder to significantly reduce the complexity and cost of the entire motor package. In addition, this feature will reduce alignment time and improve switching accuracy due to lower hysteresis, as compared to a conventional Hall sensor device.

6-channel optical encoder

Avago Technologies' state-of-the-art 6-channel optical encoder has been designed to help motor manufacturers to easily assemble the BLDC motor system. The optical encoder provides channel A, channel B, and channel I as position feedback and channel U, channel V, and channel W to emulate the Hall sensor feedback for commutation. All these output signals are generated from the optical sensors where the number of pole-pairs can be configured to the Codewheel pattern without any change to the complicated hardware design. This feature helps to significantly reduce the motor manufacturers design time-to-market. In addition, the switching accuracy is known to be much better than conventional Hall sensors where the commutation accuracy for Avago's 6-channel optical encoder is rated at ±1° mechanical.

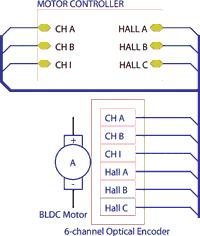

Avago Technologies' 6-channel optical encoder is available from 1000 CPR to 2500 CPR, and the shaft diameter is available from 3 mm up to 10 mm. An alignment tool is also available to ease the manufacturer in aligning the 6-channel optical encoder to the motor shaft. An example of a 6-channel optical encoder mounted BLDC motor is illustrated in Figure 2.

Comparison to conventional feedback

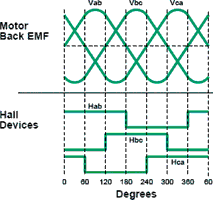

Since a conventional BLDC motor system uses a Hall sensor to detect the location of the stator with respect to the rotor, the sensors' outputs are related to the motor back-EMF. Figure 3 shows the relationship between the motor back-EMF and Hall sensors' outputs.

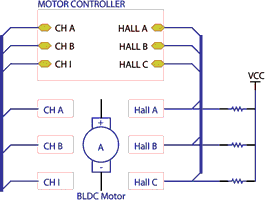

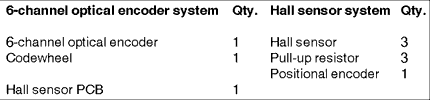

For a 3-phase BLDC motor, three Hall sensors are placed on a separate PCB spaced 120° apart. A conventional Hall sensor device is offered with an open-collector configuration that requires a pull-up resistor for each Hall sensor. This configuration further increases the motor system bill of materials; thus, increases the entire motor package costs. Figure 4 illustrates the conventional system with Hall sensor commutation feedback.

With the 6-channel optical encoder with integrated commutation outputs, only an optical encoder and Codewheel are needed as feedback for the BLDC motor. Figure 5 shows a simplified version of the same BLDC motor design as shown in Figure 4 with the 6-channel optical encoder.

By comparison, the illustration in Figure 5 clearly shows that the 6-channel optical encoder system is not as complex when compared to the system that uses the Hall sensor device. Table 1 shows the comparison between the bill-of-material for the 6- channel optical encoder and Hall sensor device.

Conclusion

Avago Technologies' 6-channel optical encoder provides position feedback for servo applications and commutation feedback. With these features, it shows that Avago's 6-channel optical encoder will help to significantly simplify BLDC motor design.

© Technews Publishing (Pty) Ltd | All Rights Reserved